- 34 -

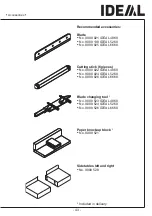

IDEAL 4860

•

IDEAL 5260

•

IDEAL 6660

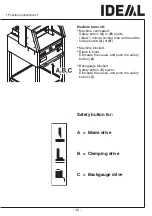

A

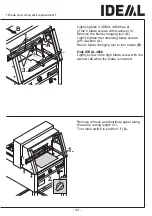

3.

.

.

2.

A

1.

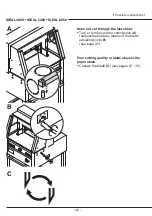

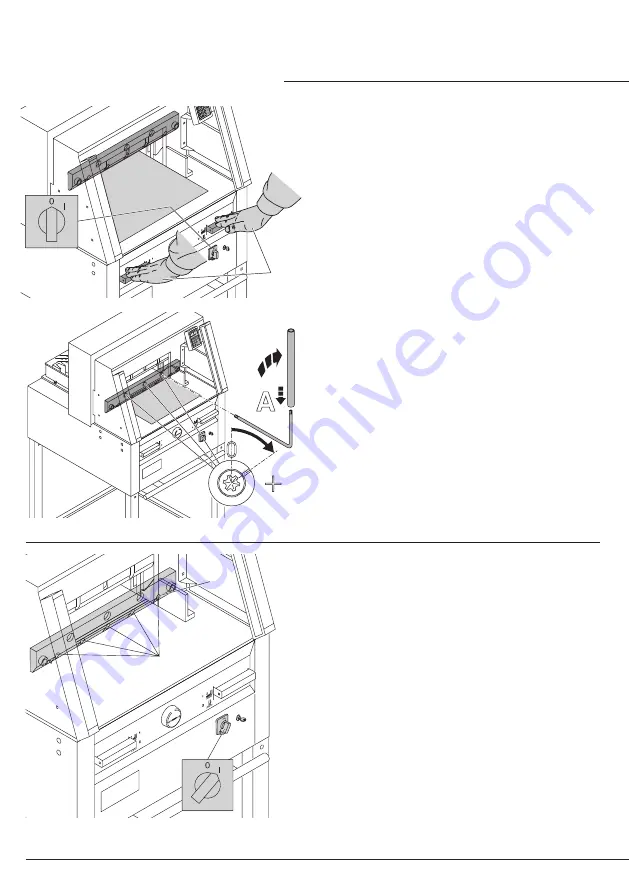

Lower the blade by pressing both cutting

buttons (

1.

). Keep one button pressed and

turn off the main switch (

2.

).

With the special wrench (

A)

the 3 eccentrics

should be screwed down (

3.

)until the paper is

cut along the entire length of the blade

(The blade must remain parallel, not too deep

into cutting stick).

•

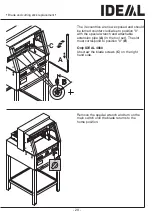

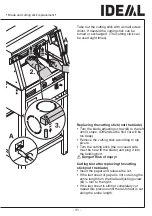

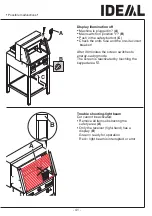

Blade and cutting stick replacement

•

Only IDEAL 4860

Tighten the blade screws (

A

) on the right hand

side.

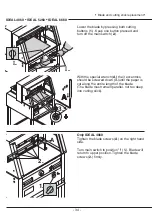

Turn main switch to position "I" (

1.

). Blade will

return to upper position. Tighten the blade

screws (

2.

) firmly.