4

Oct. 2018

A-2200IEH-XR

5. Keep everyone clear of the lift when the lift is moving, the locking mechanism is disengaged, or the

vehicle is in danger of falling.

6. Unauthorized personnel should never be in the shop area when the lift is in use.

7. Inspect the lift daily.

The lift should never be operated if it has damaged components, or is

malfunctioning.

Only qualified technicians should service the lift.

Replace damaged components

with manufacturer’s parts, or equivalent.

8.

Keep the area around the lift clear of obstacles.

9.

Never override the self-returning lift controls.

10. Avoid excessive rocking of the vehicle when it is on the lift.

11. To reduce the risk of personal injury, keep hair, loose clothing, fingers, and all body parts away from

moving parts.

12. To reduce the risk of electric shock,

do not

use the lift when wet, do not expose the lift to rain.

13. To reduce the risk of fire,

do not

operate equipment in the vicinity of open containers of flammable

liquids (gasoline).

14. Use the lift only as described in this manual,

use only manufacturer’s recommended attachments.

15. The maintenance procedures described in this manual can be done by the lift

’s owner/employer. Any

other procedure should only be performed by trained lift service personnel.

These restricted

procedures include, but are not limited to, the following: cylinder replacement, platform&

safety latch replacement, motor replacement, oil replacement& refilling and lubrication.

16. Anyone who will be in the vicinity of the lift when it is in use should familiarize themselves with

following Caution, Warning, and Safety related decals supplied with this lift, and replace them if they

are illegible or missing.

17. Never move the lift when the vehicle is loaded.

18. Only use on a level concrete surface with a recommended minimum thickness of 4

”. DO NOT install

on an asphalt surface.

19. Only remove the vehicle when the lift platform is at the lowest position.

20. Never lift the vehicle with person

’s riding on it.

Summary of Contents for A-2200IEH-XR

Page 5: ...5 Oct 2018 A 2200IEH XR 1 4 Caution and Warning Labels...

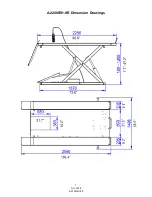

Page 7: ...7 Oct 2018 A 2200IEH XR A 2200IEH XR Dimension Drawings...

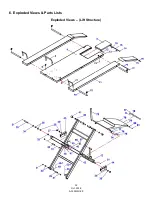

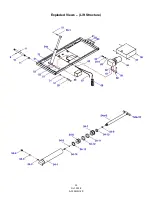

Page 14: ...14 Oct 2018 A 2200IEH XR 6 Exploded Views Parts Lists Exploded Views Lift Structure...

Page 15: ...15 Oct 2018 A 2200IEH XR Exploded Views Lift Structure...

Page 16: ...16 Oct 2018 A 2200IEH XR Exploded Views Lift Structure...