13

INSTALLATION

Classic

Slimline FF

-

Installation & Servicing

REAR FLUE OUTLET

Note.

If the

terminal is to be

sited within 25-

40mm of a corner

or vertical pipe

(refer to Table 3)

then the hole

MUST be

accurately cut and

the rubber

weather seal

trimmed around

the groove

provided.

The terminal wall

plate need not be

fitted.

Note.

Check all of the hole positions BEFORE drilling

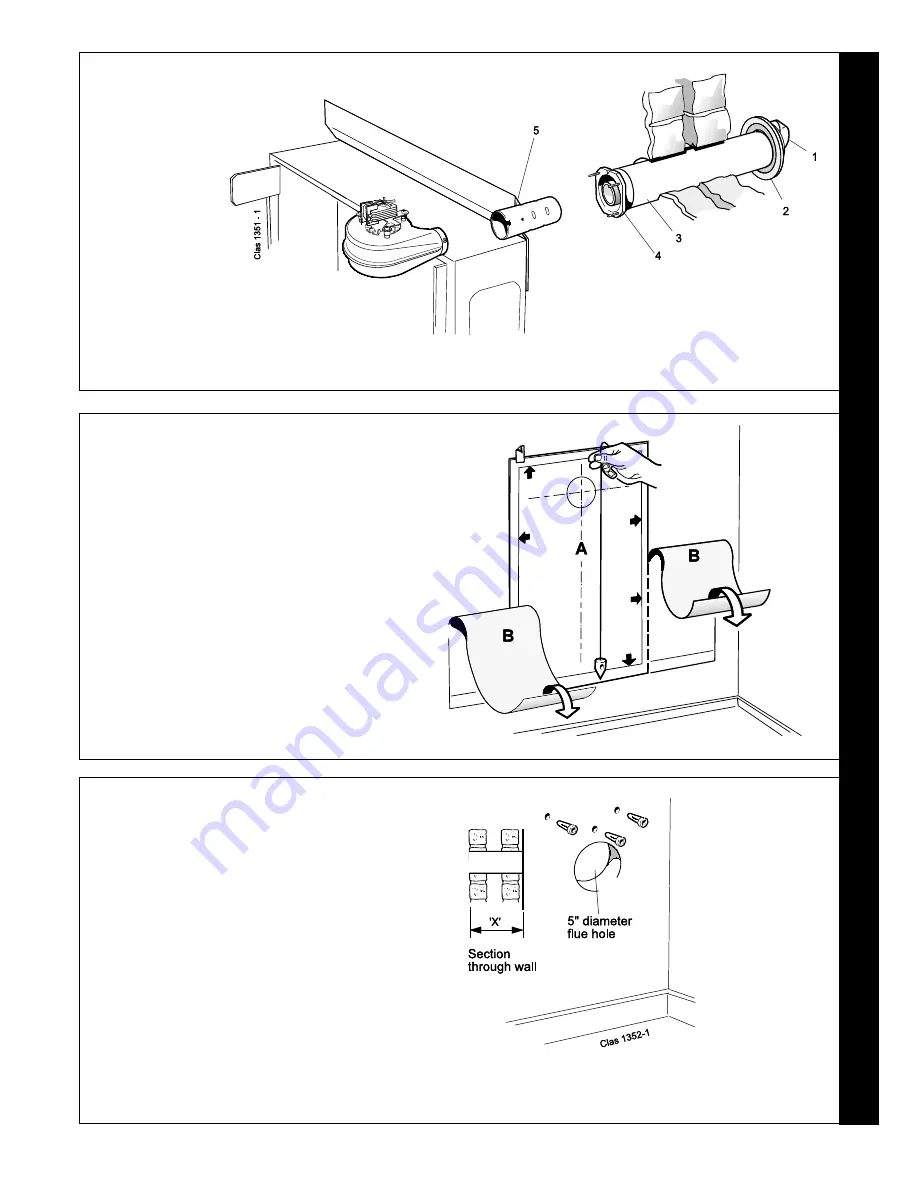

11 FLUE ASSEMBLY - Exploded View

LEGEND

1.

Terminal.

2.

Weather seal.

3.

Flue assembly.

4.

Boiler sealing ring.

5.

Flue extension tube.

1.

An optional flue

duct extension kit

is required for

wall thicknesses

greater than

600mm (23

1/2

")

Refer to Frame 10.

2.

When cutting the

ducts, always use

the cardboard

support rings

provided.

1.

Separate the templates.

2.

Tape the templates into the selected position.

3.

Ensure squareness by hanging a plumb line as shown.

4.

Mark onto the wall (if required) the following:

a.

The wall mounting plate screw positions (choose

one from each group).

Note.

Mark the centre of the

flue hole as well as the circumference.

b.

The position of the flue duct hole.

5.

Remove the templates from the wall.

IMPORTANT.

Ensure that, during the cutting operation,

masonry falling outside of the building does not cause damage

or personal injury.

1.

Cut the flue hole, preferably with a 125mm (5") core boring

tool, ensuring that the hole is square to the wall. If the hole

has been quite accurately cut with a drill then making good

the wall faces is not essential as seals are provided at both

ends of the flue. However, both wall faces immediately

around the cut hole should be flat; make good if necessary.

For less accurate holes make good to approximately

125mm (5") diameter at the 2 wall faces.

2.

Drill 2 holes for the wall mounting plate with an 8mm (

5/16

")

masonry drill.

3.

Drill 1 further hole above the flue hole for boiler fixing with

the same 8mm (

5/16

") drill.

4.

Insert the plastic plugs provided.

13 PREPARING THE WALL

12 WALL MOUNTING TEMPLATE