15

Classic LX, RS -

Installation

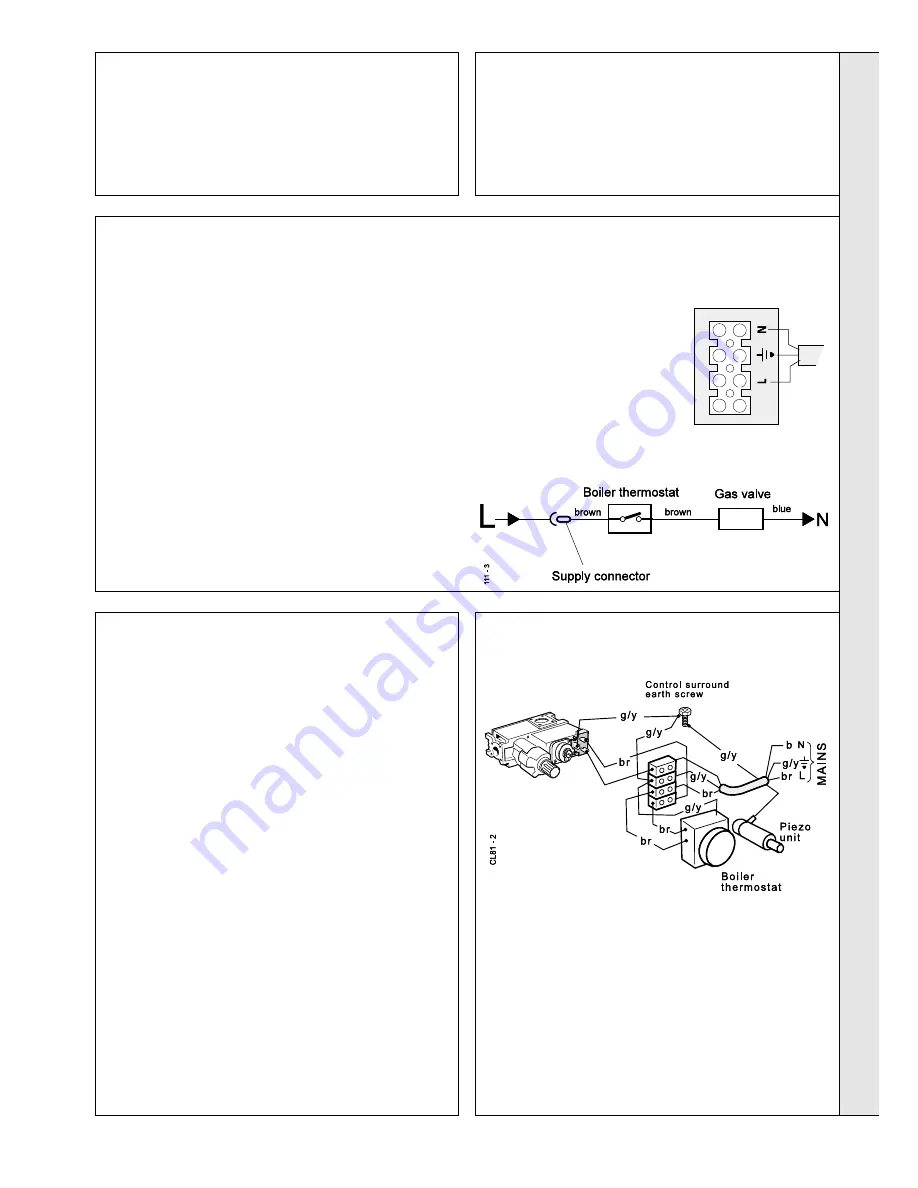

The internal wiring of the control box is shown in Frame 19.

DETAIL OF CONTROL BOX TERMINALS

Note.

In order to connect the incoming mains wires, first remove the

control box fixing screw then pull the box

forward and downward to disengage.

Ensure that the earth lead is longer than the

live and neutral so that if the cable slips in

its anchorage the current conductors

become taut before the earth conductor and

that the cable is routed through the strain

relief clamp. Ensure all cables are secure

and that no basic insulation is accessible

outside of the control box.

15 GAS CONNECTION

A MINIMUM gas pressure of 20 mbar (8 in.w.g.) MUST be

available at the boiler inlet, with the boiler operating.

The main gas cock is on the left hand side of the gas control

valve, as shown.

To facilitate connection the gas cock may removed from the gas

control valve.

16 WATER CONNECTIONS

1.

Remove the plastic plugs from the flow and return

pipes.

2.

Make all water connections and check for water

soundness.

LEGEND

b

blue

br

brown

g/y

green/yellow

INSTALLATION

INST

ALLA

TION

WARNING.

The appliance MUST be efficiently earthed.

A mains supply of 230 V ~ 50 Hz is required.

All external controls and wiring MUST be suitable for mains

voltage. Wiring should be in 3-core PVC insulated cable NOT

LESS than 0.75 mm

2

(24 x 0.2 mm) to BS.6500, Table 16.

Wiring external to the boiler MUST be in accordance with current

l.E.E. (BS7671) Wiring Regulations and local regulations.

Connection must be made in a way that allows complete isolation

of the electrical supply - such as a double pole switch, having a

3mm (1/8") contact separation in both poles, or a plug and socket

serving only the boiler and system controls. The means of

isolation must be accessible to the user after installation.

Note.

If the optional Programmer Kit is to be fitted, refer to

the instructions provided with the kit, ignore this frame and go

to Frame 18.

The wiring diagrams illustrated in Frames 20-23 cover the systems

most likely to be fitted to this appliance.

For wiring external controls to the

Classic RS

boiler, reference

should be made to the system wiring diagrams supplied by the

relevant manufacturer, in conjunction with the wiring diagrams shown

in Frames 19-23.

Difficulty in wiring should not arise, providing the following directions

are observed:

1.

Controls that switch the system ON and OFF, e.g. a time switch,

MUST be wired, in series, in the live mains lead to the boiler.

2.

Controls that override an ON/OFF control, e.g. a frost thermostat,

MUST be wired into the mains lead, in parallel, with the control(s)

to be overridden - refer to Frame 23.

3.

Controls that switch the circulation pump only ON and OFF, e.g. a

room thermostat, MUST be wired in series with the pump in the

live pump lead.

4.

If a proprietary system is used, follow the instructions supplied by

the manufacturer.

5.

SYSTEM DESIGNS FEATURING CONTROLS OR WIRING

ARRANGEMENTS WHICH ALLOW THE BOILER TO FIRE WHEN

THERE IS NO PUMPED OR GRAVITY CIRCULATION TAKING PLACE

SHOULD NOT BE FITTED.

Advice on required modifications to the wiring may be obtained from

the component manufacturers.

Notes 1.

Connections between a frost thermostat and the time

control should be made without disturbing other

wiring.

2.

A frost thermostat should be sited in a cool place in

the house, but where it can sense heat from the system.

19 PICTORIAL WIRING

FLOW WIRING DIAGRAM

18 EXTERNAL CONTROLS

17 ELECTRICAL CONNECTIONS

Summary of Contents for Classic LX RS 230

Page 1: ......