15

Concord CXC -

Installation

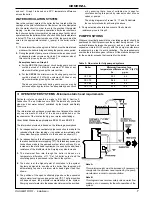

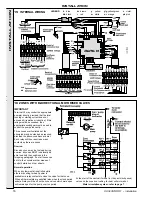

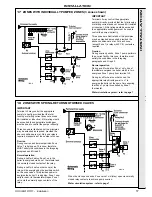

14 ELECTRICAL CONNECTIONS

WARNING.

This boiler must be efficiently earthed.

The internal wiring of the boiler control box is shown in Frame

15.

Connection must be made in a way that allows complete

isolation of the electrical supply - such as a double pole switch,

having a 3mm (1/8") contact separation in both poles, or a

plug and socket serving only the boiler and system controls.

The means of isolation must be accessible to the user after

installation.

This should serve only the boiler, together with its controls and

pumps. The supply must be wired direct to the boiler control

box and must not be interrupted by any system controls. The

pump(s) and any system controls must be wired back to the

boiler control box.

The control box incorporates a pump overrun device which is

necessary to dissipate residual heat after plant shutdown. It is

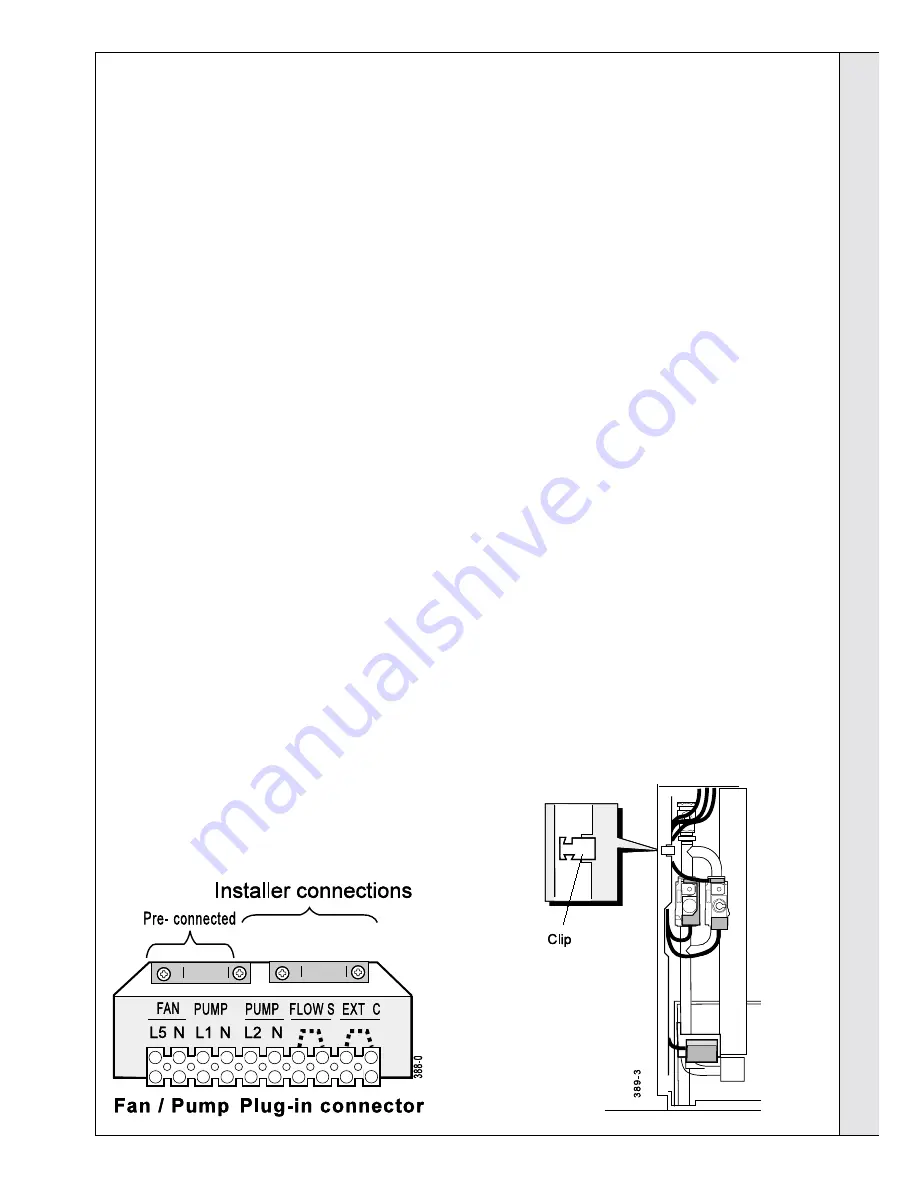

essential that the main pump is wired to the pump terminals

marked L2, N on the plug-in mains voltage connector shown

below and in Frame 15.

If no external controls are fitted it is essential that a link is

wired in place of one on the "Fan/pump plug-in connector".

The flow switch should be connected via volt-free contacts to

the 'Flow S' terminals. A link may be fitted in place of the flow

switch but the control will not be able to analyse the faulty flow

switch, if such a failure should occur. Either of the above must

be fitted or the boiler will not operate.

Any system controls should be connected, via volt free contacts,

to the terminals marked 'EXT C'. Do NOT connect an external

clock to these contacts or any mains voltage. If no external

controls are fitted a link must be fitted across EXT C.

The boiler provides frost protection via the boiler sensor. If an

external frost thermostat is required contact Caradon

Plumbing Limited.

Wiring should be PVC insulated cable, not less than 0.75mm

2

(24/0.2mm). All fuses must be ASTA approved to BS. 1362.

The length of the conductors between the cord anchorage

and the terminals must be such that the current conductors

become taut before the earthing conductor, if the cable or

cord slips out of the cord anchorage.

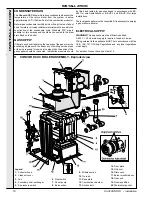

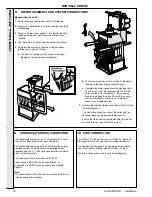

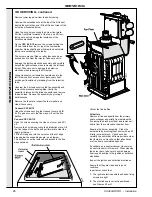

BOILER CONNECTIONS

Ensure the boiler is ELECTRICALLY ISOLATED.

The live supply cable should be fitted before assembly of the

jacket - see Frame 12 for details.

All wiring between entry at the rear of the boiler and the

connection box must be secured neatly under the cable

clips provided.

Wiring must never be allowed to come into contact with

any heated surfaces.

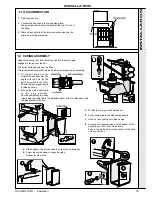

1. Check that the mains plug is pushed firmly into its socket.

2. Check that the temperature/float/air pressure plug-in

connector is fitted into the RH connection box.

3. Carefully route the electrical leads from the gas valve/

spark generator behind the LH panel return and secure

with the clip as shown.

Fit this plug-in connector into the bottom connection

box.

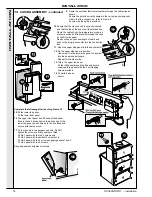

4. Route the fan and shunt pump cables through the clips

at the top of the LH side panel.

5. Wire the main system pump (L2 & N), flow switch and

external controls into the Fan/pump plug-in connector

(see below). The earth wires should be looped back

through the cable clamps and fixed to the earth post as

shown in Frame 13.

The earth connections MUST NEVER be omitted.

6.

Fit the fan/pump plug-in connector into the mains voltage

connection box behind the control box.

INSTALLATION

INST

ALLA

TION

Summary of Contents for Concord CXC 116

Page 1: ......

Page 38: ...38 Concord CXC Installation NOTES ...