20

Concord CXC -

Installation

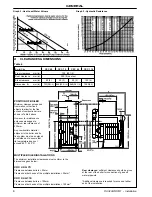

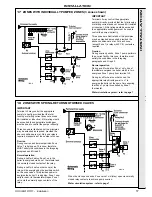

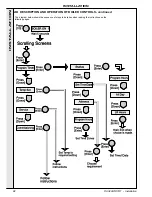

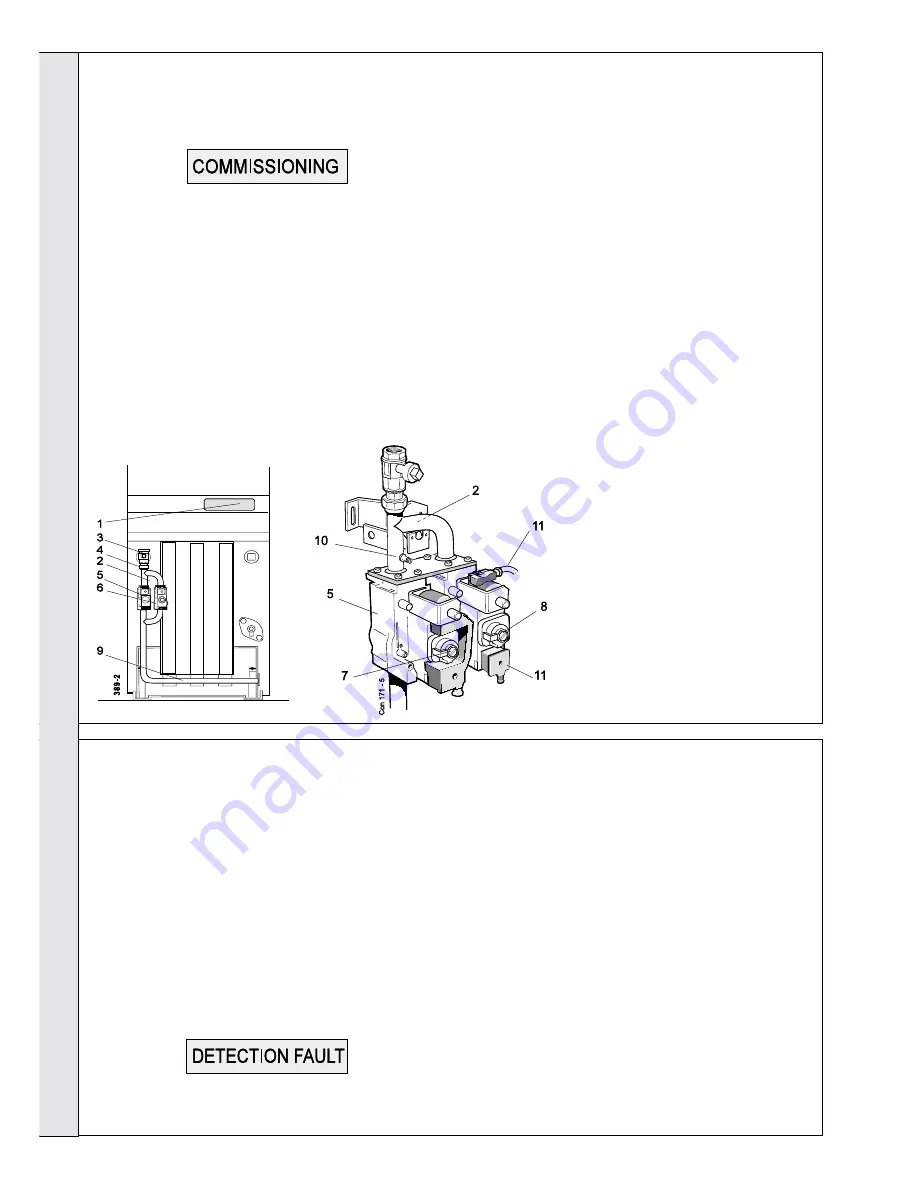

24 ADJUSTING THE MANIFOLD PRESSURES

1. Press the [ENTER] button on the fascia panel, then press

either the up or down arrow button until the display shows:

then press [ENTER]. The microprocessor is now in

commissioning mode. Failure to enter the commissioning

mode will result in a fault condition being detected when

the following actions are carried out.

2. If desired, it is possible to use the onboard commissioning

instructions using the up/down arrow buttons. However the

following paragraphs provide more detailed instructions

and are recommended until the installer is familiar with the

Concord CXC.

3. It is ESSENTIAL to adjust the LOW setting first.

4. Press the [0/1] button to turn the appliance OFF, then

disconnect the power leads from the right hand (HIGH)

gas valve.

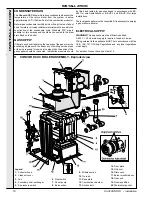

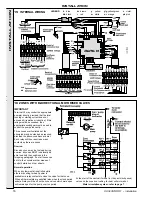

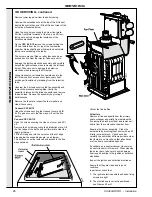

LEGEND

1. Fascia panel display.

2. Overheat thermostat reset button.

3. Main gas inlet cock.

4. Union.

5. Gas control valve low rate.

6. Gas control valve high rate.

7. Low rate adjusting screw.

8. High rate adjusting screw.

9. Burner setting pressure test point.

10. Inlet pressure test point.

11. RH (high) gas valve power

connector.

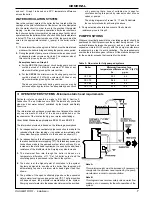

The Concord CXC features direct burner ignition, high/low

burner operation, and a microprocessor control system.

Upon a demand for heat, the controls start the fan, the air

pressure switch senses flow then the controls open the low

rate gas valve and provides a rapid spark at the ignition

electrode for up to 10 seconds.

The burner will light and remain at low rate for approximately 3

minutes before proceeding to high rate (when the

microprocessor opens the remaining gas valve).

If the boiler fails to light, the gas valve is closed and there will

be a delay of 1 minute before the cycle is repeated. If, after 5

attempts, the burner has failed to light, the boiler will go to

lockout and

will be displayed on the screen.

When the boiler flow temperature reaches the thermostat set

point, the controls will turn the burner to low rate. If the flow

temperature continues to rise, the burner and fan will be

turned off at 3

o

C above the set point.

If, however, the temperature falls below the set point whilst on

low fire, the controls will automatically turn the burner back up

to maximum rate.

This system has the advantages of ensuring that the boiler

accurately maintains the set temperature (without the large

temperature swings that can be associated with on/off

boilers), prevents rapid or short cycling, and provides more

efficient system operation.

CXC 94 & 116 ONLY

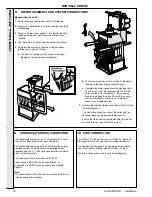

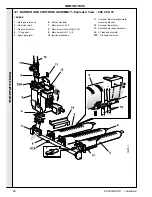

5. Press the [0/1] button again to light the burner. Allow the

burner to run at low rate for several minutes then check

that the low burner pressure is as shown in Table 1 for

the appropriate boiler size. If necessary, adjust the low

burner pressure adjusting screw (7).

6. Press the [0/1] button to turn the boiler off, reconnect the

power leads to the RH valve and press the [0/1] button

again to relight the boiler. Adjust the system controls to

allow the boiler to fire at high rate for several minutes,

then remove the dust cover and adjust the high burner

pressure adjusting screw (8). After setting to the indicated

pressure replace the dust cover and allow the boiler to

operate for about 5 minutes to stabilise then recheck the

burner pressure.

Note.

If high rate pressure is not achievable as above

check that the gas restrictor in the low-rate valve is fitted

(see Frames 39 & 42).

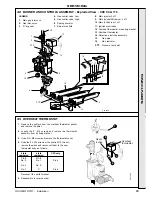

7. Press the [0/1] button to turn the boiler off, then refit both

pressure test point screws. Check for gas soundness.

8. Press [EXIT] to leave the commissioning mode and

return to the main menu.

9. Press [EXIT] again to return to the status displays.

INSTALLATION

INST

ALLA

TION

25 OPERATING INSTRUCTIONS

Summary of Contents for Concord CXC 116

Page 1: ......

Page 38: ...38 Concord CXC Installation NOTES ...