9

Concord CXC -

Installation

GENERAL

capacity to support the weight of the boiler (when filled with water)

and any ancillary equipment.

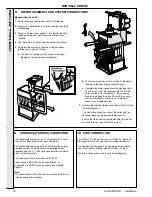

If the boiler is mounted on a plinth then the dimensions must exceed

the plan area of the boiler by at least 75mm on each side.

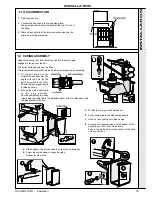

VENTILATION

Safe, efficient and trouble-free operation of conventionally flued

gas boilers is vitally dependent on the provision of an adequate

supply of fresh air to the room in which the appliance is installed.

Ventilation by grilles communicating directly with the outside air is

required at both high and low levels. The minimum free areas of

these grilles must be according to the scale in Table 6.

Position ventilation grilles to avoid the risk of accidental obstruction

by blockage or flooding. If further guidance on ventilation is required

then consult BS.6644.

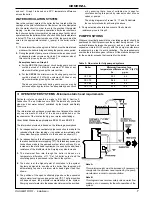

AIR SUPPLY BY MECHANICAL VENTILATION

The supply of air by mechanical means to a space housing the

boiler should be by mechanical inlet with natural or mechanical

extraction. Mechanical extract ventilation with natural inlet

must

not

be used.

Where a mechanical inlet and a mechanical extract system is

applied, the design ventilation flow rates should be as in Table 4 of

BS.6644.

The requirements for air supply by mechanical ventilation are given

in BS.6644.

Note.

For mechanical ventilation systems an automatic control

should be provided to cause safety shutdown or lockout of the

boiler(s) in the event of failure of air flow in either inlet or extract

fans.

IMPORTANT.

The use of an extractor fan in the same room as the

boiler (or in an adjacent, communicating room) can, in certain

conditions, adversely affect the safe operation of the boiler. Where

such a fan is already fitted (or if it is intended to fit an extractor fan

after installation of the appliance) the advice of the gas supplier

should be obtained.

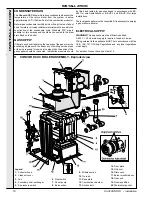

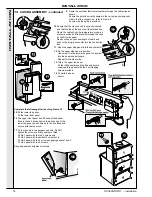

FLUE SYSTEM DESIGN

The

Concord CXC

condensing boiler is supplied with an integral

fan which is fully matched to the boiler in each case to provide

correct combustion air flow.

The power of this fan is such that there is a large reserve of pressure

available to overcome a significant length of the flue without

affecting the combustion performance of the boiler. The pressure

available at the base of the flue to overcome flue resistance is

0.25 mbar (0.1 w.g.) This is sufficient to overcome the resistance

of approximately 30 metres of 150mm diameter smooth, straight

flue pipe.

Material

The type of flue pipe used should conform BS.715: Section 2

Stainless Steel or be of equivalent corrosion resistance. Advice

regarding the availability of proprietary types of flue system can

be obtained by contacting

Caradon Plumbing Ltd.

All joints or

connections in the flue system must be impervious to condensate

leakage and also any low points in the flue system should be

drained using pipe of material resistant to condensate corrosion.

Care should also be taken in the selection of flue terminals as

these tend to accentuate the formation of a plume.

Care should be taken to ensure the specification of the chimney is

suitable for the application by reference to the manufacturers

literature.

Caradon Plumbing Ltd

can offer advice on the design

of suitable chimney systems.

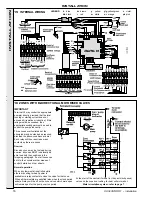

INSTALLATION REQUIREMENTS

The appliance must be installed by a CORGI registered installer,

identified by . The installation of the boiler must be in accordance

with the relevant requirements of the Gas Safety Regulations, current

IEE (BS.7671) Regulations, Model Water Bye-laws, local water

authority bye-laws and it should also comply with any relevant

requirements of the local gas supplier, local authority and the relevant

British Standard Codes of practice and building regulations.

Limitations of Intended Operating Environment

These appliances are

NOT

suitable for installation where they will

be exposed to the elements.

A boiler room shall be constructed or adapted to meet the

requirements of BS. 6644.

The maximum ambient temperature is 32° C at 1.5 metres from

the floor, with a maximum humidity of 90% RH.

FOR SMALL PIPE INSTALLATIONS:

BS. 6891:

Installation of low pressure pipework

FOR LARGE PIPE INSTALLATIONS

Gas Installations

IGE-UP-1:

Purging Procedures of Non-domestic Gas

Installations. Soundness Testing Procedures

for Industrial and Commercial.

IGE-UP-2:

Guidance notes on the Installation of Gas

Pipework, Boosters and Compressors in

Customer’s Premises Equal to or Greater

than 25mm (Non-domestic).

IGE-UP-10:

Installation of Gas Appliances in Industrial and

Commercial Premises.

BS.6644:

Installation of Gas Fired Hot Water Boilers

70kW to 1.8MW (net).

BS 6880 Pt 1-3: Control Heating by Low Pressure Hot Water.

CP342:2:

Centralised Hot Water Supply.

Model Water Bye-laws

Manufacturers notes must not be taken, in any way, as

overriding statutory obligations.

The appliance must be installed in a room separated from living

rooms and provided with appropriate ventilation direct to the outside

- see Table 6.

2.

Artificially softened water must not be used in the system, under

any circumstances.

3.

In all systems the fitting of a filter to the return pipework, in order

to prevent debris reaching the heat exchanger, is essential.

FOUNDATION

The boiler must stand on a non-combustible floor (i.e. concrete

or brick) which must be flat, level and of a suitable load bearing

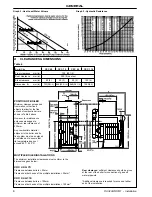

Table 6 - Ventilation Requirements

Required area (cm

2

) per kW of total rated input (net)

Boiler room

Enclosure

Low level (inlet)

4

10

High level (outlet)

2

5

Note: Where a boiler installation is to operate in summer

months (e.g. DHW) additional ventilation requirements

are stated, if operating for more than 50% of time (refer

to BS6644).

138423-7.pmd

11/7/2005, 9:48 AM

9

Summary of Contents for Concord CXC 116

Page 1: ......

Page 38: ...38 Concord CXC Installation NOTES ...