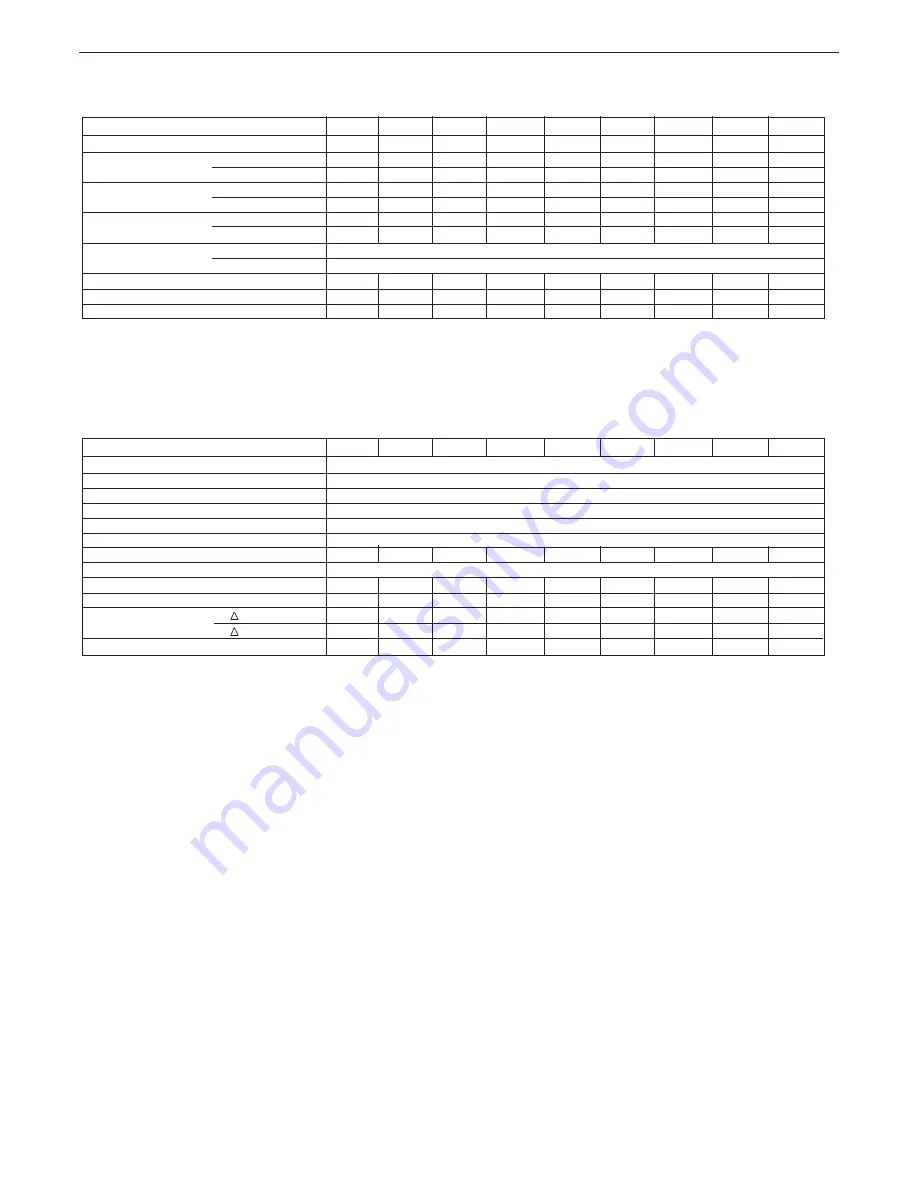

2

Concord ESi

- Installation and Servicing

GENERAL

Boiler

ESi 140

ESi 160

ESi 180

ESi 200

ESi 220

ESi 260

ESi 300

ESi 340

ESi 380

Number of Sections

8

9

10

11

12

14

16

18

20

Boiler Output

2nd stage kW 119-140 136-160 153-180 170-200 187-220 221-260 255-300 289-340 323-380

1st stage kW

83-98

95-112 107-126 119-140 131-154 155-182 179-210 202-238 226-266

Boiler Input

2nd stage kW

131,1-153 149,7-174,7 168,2-196,3 186,7-217,9 205,2-239,4 242,2-282,6 278,8-325,4 315,7-368,4 352,4-411,3

(Nett CV)

1st stage kW

93,1-108,9 106,3-124,3 119,4-139,7 132,5-155 145,6-170,4 171,9-201,1 197,9-231,5 224-262,1 250,1-295,6

Gas

2nd stage m

3

/h

13,88-16,1915,84-18,48 17,80-20,77 19,76-23,05 21,71-25,33 25,63-29,91 29,51-34,43 33,40-38,98 37,29-43,52

flow rate

1st stage m

3

/h

9,85-11,52 11,24-13,15 12,63-14,78 14,02-16,41 15,41-18,03 18,19-21,28 20,94-24,50 23,71-27,74 26,47-30,97

Burner pressure

2nd stage mbar

8.8 - 11.8

1st stage mbar

1st stage pressure = 0.5 x adjusted 2nd stage pressure

Approx. flue gas volume

m

3

/sec

0.115

0.123

0.148

0.163

0.171

0.209

0.228

0.247

0.304

Flue Gas Temperature

ºC

125

133

123

125

130

126

133

140

126

CO

2

%

6.4

7

6.3

6.4

6.8

6.5

7

7.5

6.5

Table 1 - Performance Data

Boiler

ESi 140

ESi 160

ESi 180

ESi 200

ESi 220

ESi 260

ESi 300

ESi 340

ESi 380

Main burner injector

m m

3, 9

Ignition burner injector

m m

0,8

Maximum flow temperature

ºC

90

Maximum operating pressure

bar

6

Electrical connection

V / Hz

230 / 50

Maximum electrical power

W

450

Gas connection

(inch BSP)

1"

1"

1"

1"

1"

1"

1

/

4

1"

1

/

4

1"

1

/

4

1"

1

/

2

Flow & return connections

(inch BSP)

2"

Flue outlet diameter

m m

250

250

300

300

300

350

350

350

400

Water content

litre

61

68

76

84

91

106

122

137

154

Water circuit

at T = 11 K mbar

66

87

110

136

164

229

305

392

489

resistance

at T = 20 K mbar

16

21

27

33

40

56

75

96

120

Dry weight

kg

575

635

690

750

805

920

1035

1150

1350

Table 2 - General Data

Note

:

The above tables show both 85% and 100% full output figures. The output is adjustable.