26

Concord ESi

- Installation and Servicing

INSTALLATION

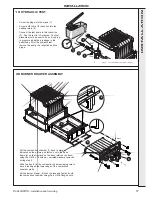

con9058

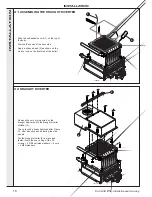

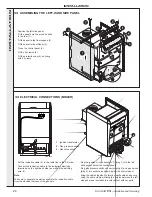

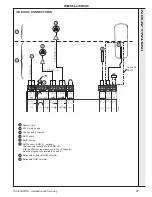

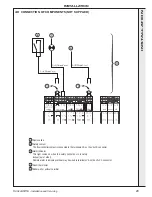

37 ELECTRICAL CONNECTIONS (EXTERNAL)

The electrical connections shall be made in compliance

with the instructions given in the electrical diagrams

supplied with the boiler and the guidelines provided in the

manual. The electrical connection must comply with the

standards in force.

Connection must be made in a way that allows complete

isolation of the electrical supply - such as a double pole

switch, having a 3mm (1/8") contact separation in both

poles, or a plug and socket serving only the boiler and

system controls. The means of isolation must be

accessible to the user after installation.

All the connections shall be made to the terminal block

provided for that purpose in the boiler control panel.

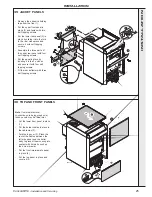

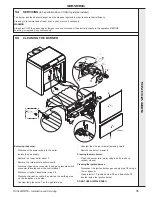

Proceed as follows to open the control panel (if required):

1.

Remove securing screws from boiler top panel.

2.

Remove boiler top panel.

3.

Unhook intermediate front panel.

4.

Remove securing screws from upper front panel.

5.

Remove upper front panel.

6.

Remove securing screws from control panel top cover.

7.

Remove control panel top cover.

8.

Remove securing screws from top of the control panel.

9.

Remove the securing screws from front of the control panel.

10.

Lower the control panel to access the connection terminal

strip.

con9056

con9057

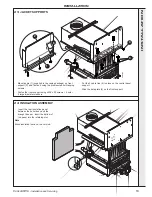

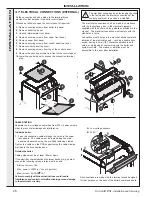

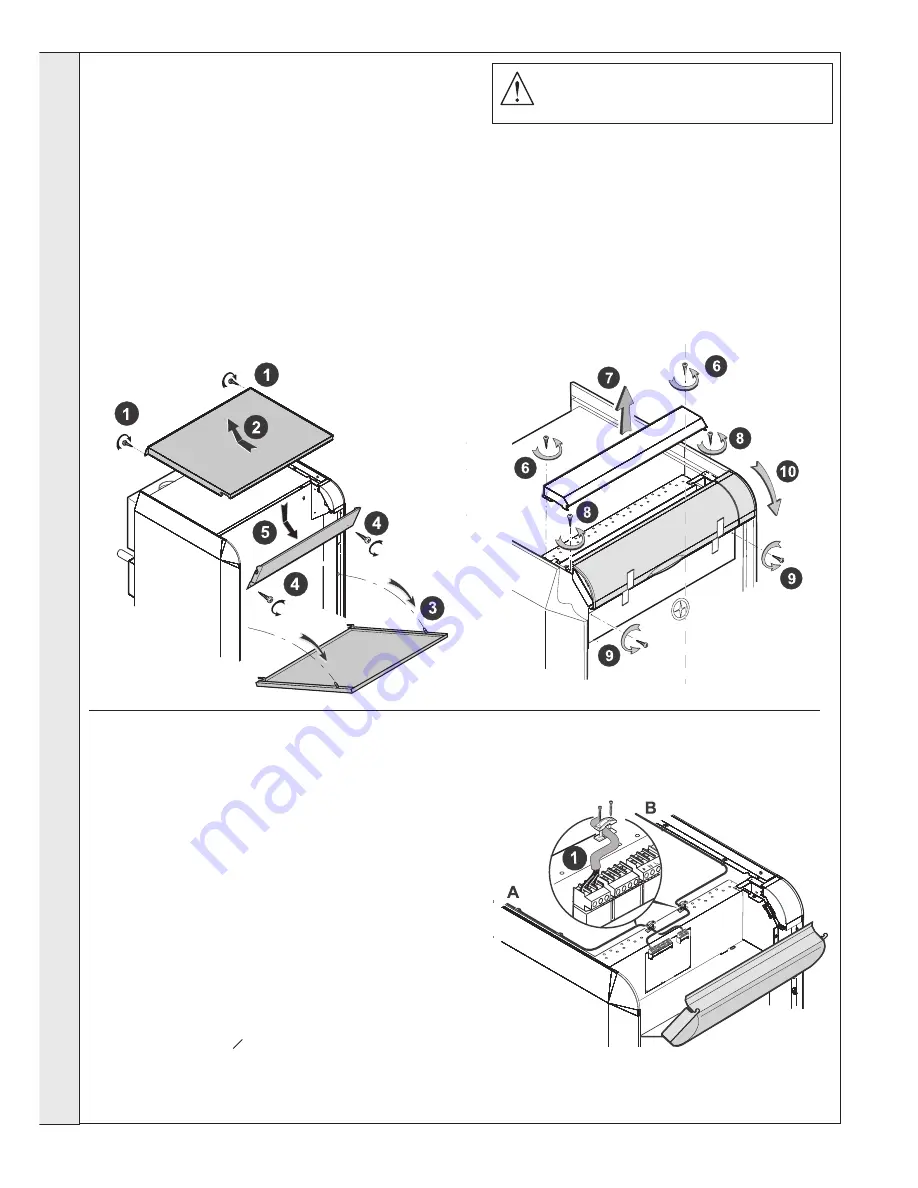

CABLE ROUTING

Separate the low voltage sensor wires from 230 V power wires in

order to prevent electromagnetic interference.

Inside the boiler:

1.

Feed the connection cables through the holes in the upper

rear panels. The cables must be routed along the side

panels and secured using the pre-fitted fastening clamps.

Tighten the cables on the PCB support using the cable clamps

provided in the accessories pack.

Outside the boiler:

Cable guides must be at least 100mm apart.

If the electrical characteristics of external devices (e.g. pumps)

exceed the following values a relay must be used.

- Start up current > 16A

- Max. power > 450W (or

1

/

2

cont. hp motor)

- Max. current > 2A COSO = 0.7

Failure to comply with these instructions could lead to

interference and control unit malfunctioning or even damage

to the electronic circuitry.

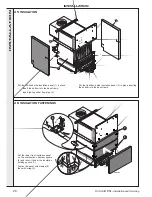

A.

Low voltage sensors

B.

230V

All connections are made with the terminal boxes designed

for that purpose on the back of the boiler's command board.

The electrical wiring has been thoroughly checked

in the factory and the internal connections of the

control panel must in no case be modified.

INST

ALLA

TION