30

Concord ESi

- Installation and Servicing

INSTALLATION

CON9061

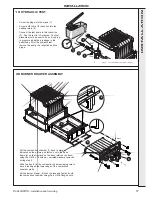

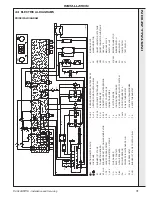

41 CONNECTING THE OPTIONAL FLUE GAS THERMOMETER KIT

(Package ID 28)

An optional flue gas thermometer may be

fitted to the front of the control panel.

Proceed as follows:

-

Cut the cover off with a knife along the

edges of the coloured rectangle.

-

Clip the thermometer into the opening.

-

Bring the sensor to the back of the

boiler via the cable channel and insert it

in the flue gas pipe.

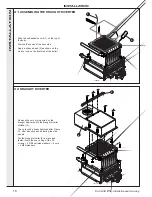

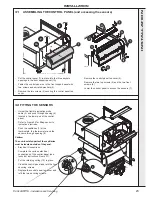

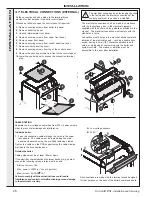

42 CONNECTING THE OPTIONAL HOUR RUN METER(S) KIT

(Package IC 8)

One or two optional hour run meters (stages 1 and 2) may be

fitted to the front of the control panel.

Proceed as follows:

-

Cut the cover off with a knife along the edges of the

coloured rectangle.

-

Pull out the 2 wires prepared in the control panel.

-

Connect the wires to the hour run meter (the wires are

interchangeable).

-

wires marked CH1 for the first stage.

-

wires marked CH2 for the second stage.

-

Clip the hour run meter into the control panel.

If the burner has 2 stages, the first stage hour run meter

displays the total burner operating time and the second hour

run meter displays the operating time of stage 2.

con9062

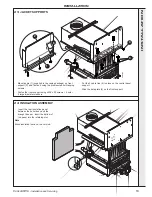

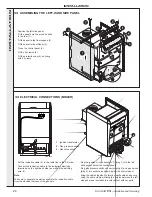

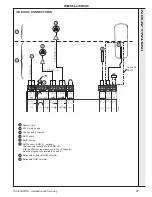

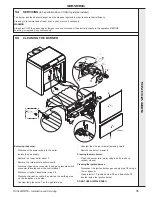

43 SETTING THE DHW PUMP OVERRUN AND LOAD TEMPERATURE LIMITER

con9063

1

2

Setting the DHW Pump Overrun

1.

The potentiometer on the PCB in the boiler is

used to adjust the DHW pump overrun.

The overrun can vary with an adjustment range

from 0 to 10 minutes (factory setting 4 min.)

Setting the Domestic Hot Water Load Temperature

Limiter

2.

The potentiometer on the P.C.B. in the boiler is

used to adjust the boiler temperature while

heating domestic hot water.

The load temperature setting can vary from 60 to

90

o

C (factory setting 75

o

C).

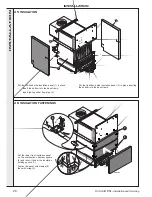

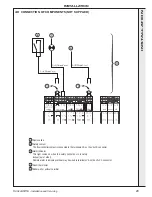

Reassembly

3.

At the end of the work, reassemble, as for access

but in the reverse order.

Note

.

Do not omit the serrated washers.

INST

ALLA

TION