Concord ESi -

Installation and Servicing

33

INSTALLATION

49

COMMISSIONING AND TESTING

GENERAL

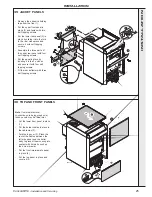

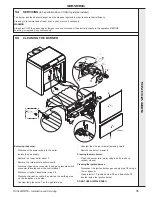

Check that all drain cocks are closed, that any stop valves fitted

to the flow and return pipes are open and that the system has

been filled and properly vented.

PURGING

Check that the electricity supply is switched OFF.

Remove the casing lower front panel.

Extinguish all naked lights and open all doors and windows.

DO NOT SMOKE. Check that the gas supply is turned ON at the

meter and open the main gas inlet cock. Loosen the union

and allow air to be purged from the gas line until gas is

smelled. Refer to BS 6891 or IGE-UP-1 for further details.

Re-tighten the union .

TESTING FOR GAS SOUNDNESS

Close the gas supply cock at the meter.

Connect a gas pressure gauge to the inlet test point. Take

particular care to ensure a gas-tight connection. Open the

gas supply cock at the meter and the appliance gas cock;

record the static pressure. Next, close the gas supply cock

at the meter. Wait for 1 minute for temperature stabilisation

then observe the pressure gauge over a period of 2

minutes.

Any leaks must be cured.

Replace all pressure test point screws.

Before turning the boiler on, make sure that the installation is

filled with water

.

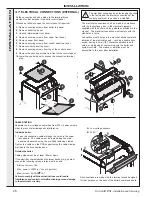

Carry out the start-up operations in the order indicated below:

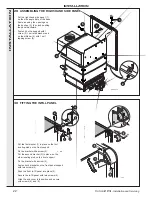

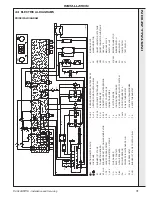

Refer to Frame 39 for identification.

•

Open the main gas shut-off valve.

•

Set the pump shutdown switch to .

•

Set the Summer / Winter switch

2

to the "Winter" position.

•

Switch on the electrical supply to the boiler.

•

Set all the controls (thermostats (7) and (12), external

controls etc.) so that heat is required.

•

Set the On / Off switch (1) to the "On" position.

•

The boiler will light and thermostat indicator light (8) will

illuminate. If it does not light the burner indicator (2) will be

illuminated. Press in and release the reset switch (2). The

controls will reset and attempt to light.

•

Check all connections for gas soundness, using leak

detection fluid.

50

INITIAL LIGHTING

48

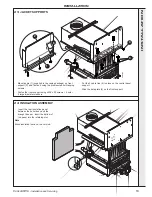

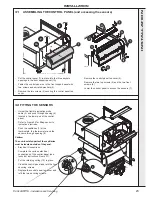

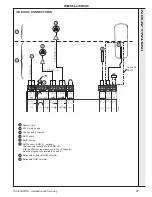

FLUE CONNECTION

1.

Complete the flue connection.

2.

Details of flue outlet sizes are given in Table 2.

3.

Seal with an approved boiler putty.

INST

ALLA

TION