34

Concord ESi

- Installation and Servicing

INSTALLATION

51

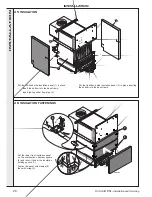

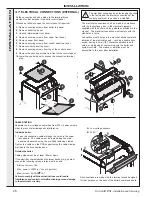

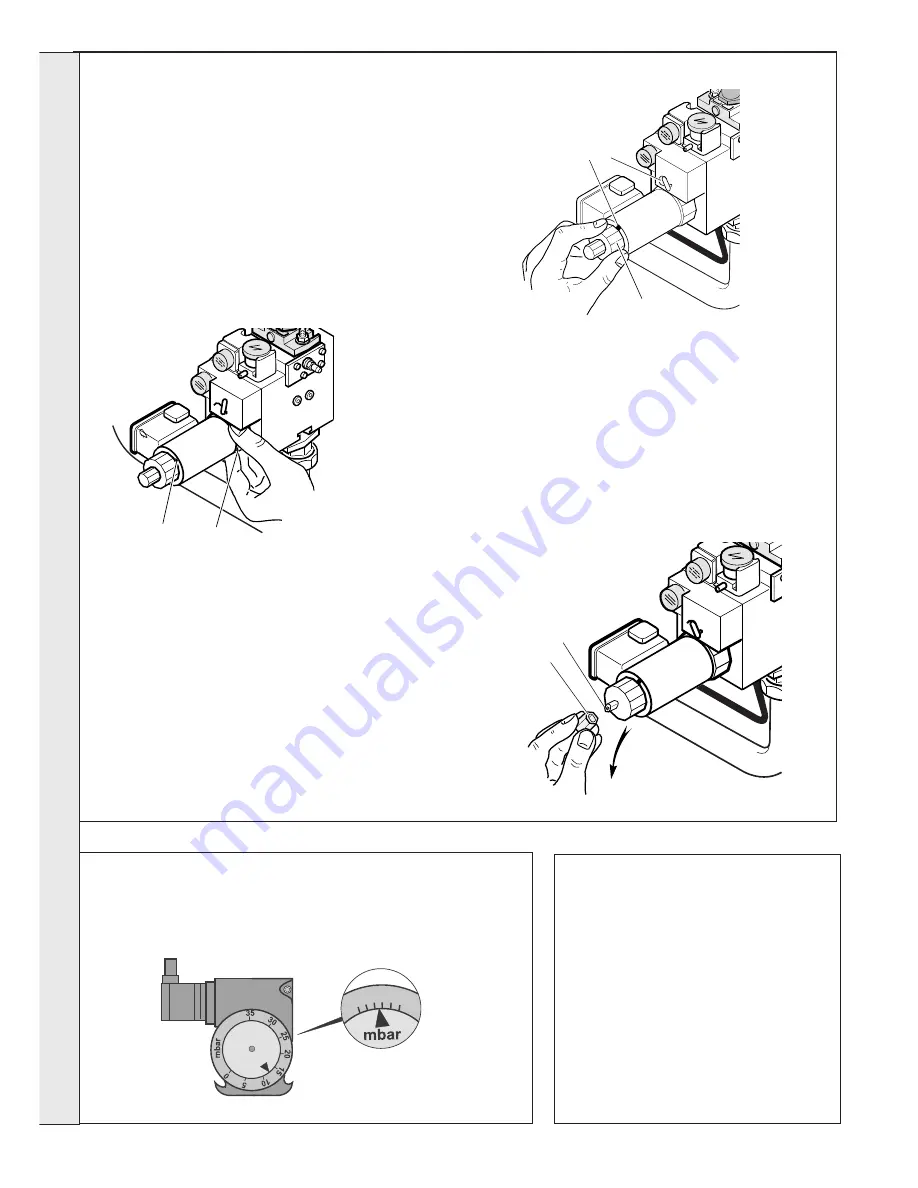

SETTING PROCEDURE

(all boilers)

+

,

*

CON5295

+

-

CON5296

/

0

CON5297

1.

Adjusting the 2nd stage pressure:

-

Connect the pressure gauge to the manifold pressure tapping.

-

Operate the boiler at the 2nd stage acting upon the thermostat(s).

-

Adjust the burner injector pressure indicated in Table 1 as follows:

• unscrew the slotted head screw

C

by approximately one turn and

unscrew completely the adjusting knob

D

(turning it counter-

clockwise), then tighten again screw

C

.

• adjust the injector pressure adjustment screw

B

of the regulator.

Clockwise rotation increases the pressure, counter-clockwise

rotation decreases it.

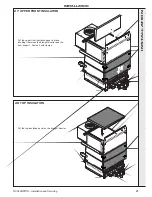

2.

Adjusting the 1st stage pressure:

-

Operate the boiler at the 1st stage acting upon the burner

operation selecting switch located on the boiler control panel.

-

Adjust the flow in order to obtain the injector pressure indicated in

Table 1 (0.5 x the 2nd stage pressure) as follows:

-

Adjust the 1st stage flow with the help of ring

E

. Clockwise rotation

decreases the pressure. Counter-clockwise rotation increases

the pressure

-

Tighten locking screw

C

.

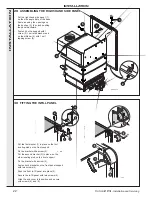

3.

Adjusting the starting rate (or initial flow):

Start rate is factory-set to the minimum (9 mb starting pressure).

Depending on the installation conditions, one may adjust the start rate

setting in order to ensure an optimal start of the boiler. The maximum

permissible is 12 mb.

Proceed as follows:

-

Unscrew protection cap

G

, turn it over and use it as a key to turn

adjusting spindle

H

until obtaining the initial flow required.

Counter-clockwise rotation increases the initial flow, clockwise rotation

decreases it.

-

After adjustment, put cap

G

back in place.

52

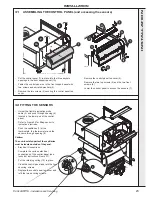

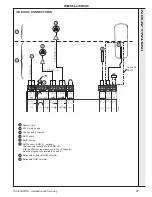

CHECKING GAS PRESSURE SWITCH

The minimum gas pressure switch fitted on the gas valve is factory set to

12.5 mbar. If the gas supply pressure drops, the minimum pressure

switch turns the boiler off.

53

SPILLAGE CHECK

Check there is no spillage of combustion

products from the boiler draught diverter by

carrying out a spillage test, as detailed in

BS. 5440:1.

con9065

INST

ALLA

TION