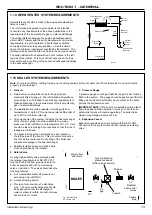

1.11 ELECTRICAL SUPPLY

Wiring external to the appliance MUST be in accordance with

the current I.E.T. (BS7671) Wiring Regulations and any local

regulations which apply. For Ireland reference should be made to

the current ETCI rules for electrical installations

The point of connection to the mains should be readily accessible

and adjacent to the boiler.

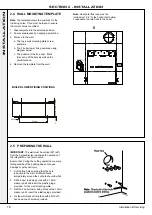

1.12 CONDENSATE DRAIN

Refer to 19

A condensate drain is provided on the boiler. This drain must be

connected to a drainage point on site. All pipework and fittings in

the condensate drainage system MUST be made of plastic -

no

other materials may be used.

IMPORTANT.

Installation must be in accordance with BS 6798.

The drain outlet on the boiler is sized for standard 21.5mm

overflow pipe. It is a universal fitting to allow use of different

brands of pipework.

11

Installation & Servicing

SECTION 1 - GENERAL

Summary of Contents for EVOMAX 2 30

Page 4: ...4 Installation Servicing...

Page 75: ...75 Installation Servicing NOTES...

Page 76: ...76 Installation Servicing NOTES...

Page 77: ...77 Installation Servicing NOTES...

Page 78: ...78 Installation Servicing NOTES...