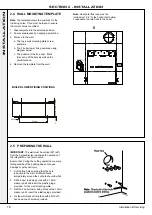

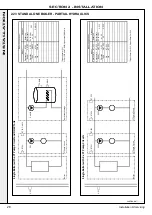

Feed/expansion

cistern

500mm

minimum

3000mm

minimum

System

flow to

pump

Inverted cold

feed entry

Cold

Feed

Water

level

(cold)

Open vent

System

return

Connections

to boiler

ima5351

3000

minimum

1.14 OPEN VENTED SYSTEM REQUIREMENTS

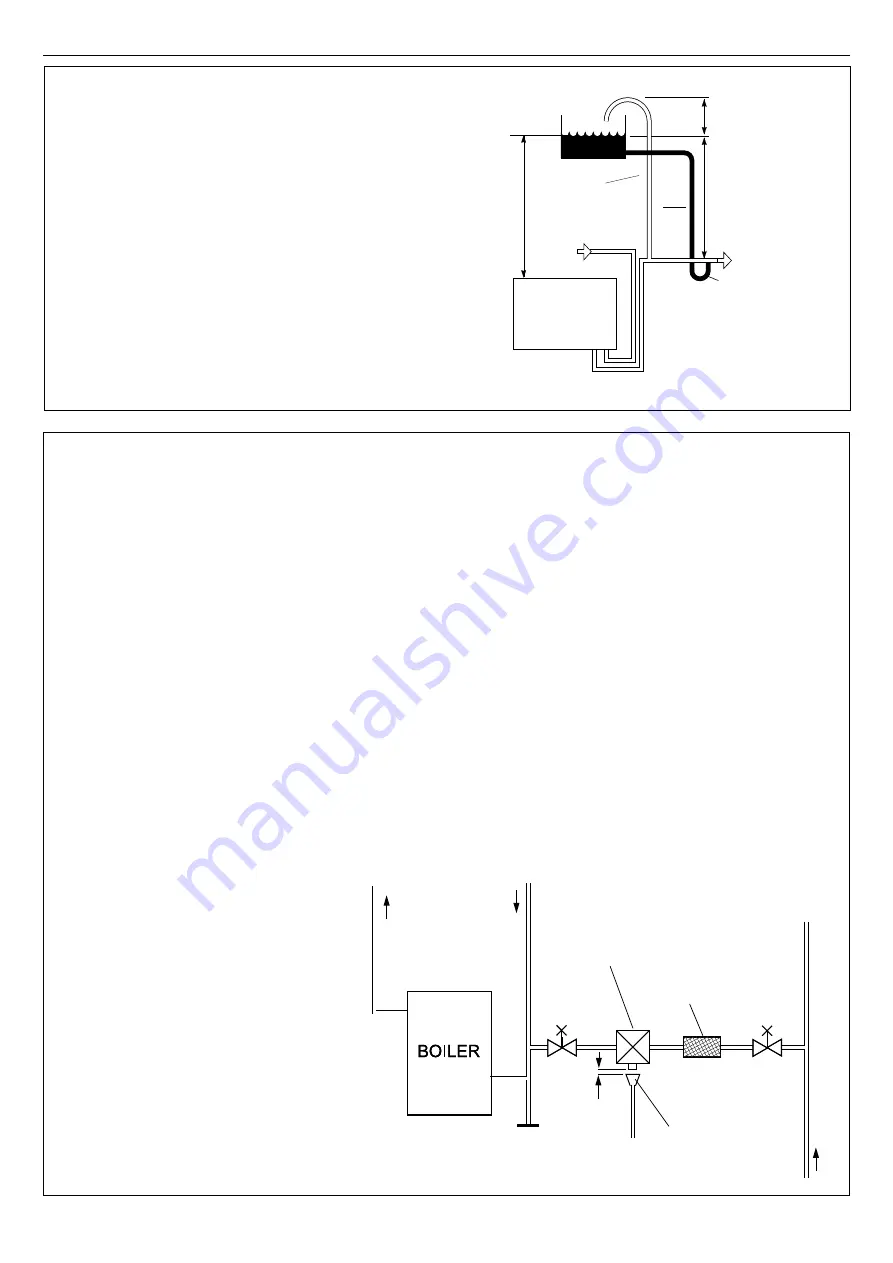

1.15 SEALED SYSTEM REQUIREMENTS

Detail reference should be made to the appropriate standards

listed on page 8.

The information and guidance given below is not intended

to override any requirements of the above publications or the

requirements of the local authority, gas or water undertakings.

The vertical distance between the pump and feed/expansion

cistern MUST comply with the pump manufacturer’s minimum

requirements, to avoid cavitation. Should these conditions

not apply either lower the pump position or raise the cistern

above the minimum requirement specified by Ideal Boilers. The

isolation valves should be fitted as close to the pump as possible.

The boiler is fitted with an automatic air vent, located in the left

top side of the interior. This air vent must never be shut off, as

this could result in dry firing of the boiler and subsequent damage

to the heat exchanger.

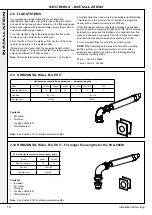

CV

CV

Resillient

seat control

valves

Supply

pipe

DT

CV = Control Valve

DT = Drain Tap

Air

gap

Tundish

Strainer

Type BA backflow

prevention device

(RPZ valve assembly)

primary flow

and return

ima7349

Note.

The method of filling, refilling, topping up or flushing sealed primary hot water circuit from the mains for a non-domestic

property is shown below.

1. General

a. Detail reference should be made to the appropriate

standards listed on page 8. The information and guidance

given below is not intended to override any requirements of

these publications or the requirements of the local authority,

gas or water undertakings.

b. The installation should be capable of working with flow

temperatures of up to 90

o

C and a temperature differential of

up to 35

o

C at minimum rate only.

c. All components of the system, including the heat exchanger

of the indirect cylinder, must be suitable for a working

pressure of 6 bar (87lbf/in

2

) and temperature of 110

o

C. Care

should be taken in making all connections so that the risk of

leakage is minimised.

d. The boiler is fitted with an automatic air vent, located in

the left top side of the interior. This air vent must never be

shut off, as this could result in dry firing of the boiler and

subsequent damage to the heat exchanger.

e. Suitable isolation valves and drain points

must be provided by the installer.

2. Safety Valve

A spring loaded safety valve complying with

the relevant requirements of BS. 6759 Pt. 1

must be fitted in the flow pipe as close to the

boiler as possible and with no intervening

valve or restriction. The valve should have the

following features:

a.

A non-adjustable preset lift pressure not

exceeding 6 bar (87lbf/in

2

).

b.

A manual testing device.

c.

Provision for connection of a discharge

pipe. The valve or discharge pipe should

be positioned so that the discharge of

water or steam is visible, but will not cause

hazard to user or plant.

3. Pressure Gauge

A pressure gauge covering at least the range 0-6 bar must be

fitted to the system. The gauge should be easily seen from the

filling point and should preferably be connected at the same

point as the expansion vessel.

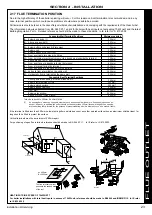

IMPORTANT NOTE:

If the boilers are installed on to an Ideal

frame & header kit and operated in excess of 3 bar then all

safety relief valves will require upgrading. The boiler has a

maximum operating pressure of 6 bar.

4. Expansion Vessel

Expansion vessels used must comply with BS. EN 13831.

Connection to the system must not incorporate an isolating

valve.

13

Installation & Servicing

SECTION 1 - GENERAL

Summary of Contents for EVOMAX 2 30

Page 4: ...4 Installation Servicing...

Page 75: ...75 Installation Servicing NOTES...

Page 76: ...76 Installation Servicing NOTES...

Page 77: ...77 Installation Servicing NOTES...

Page 78: ...78 Installation Servicing NOTES...