3.11

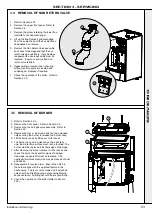

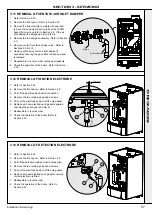

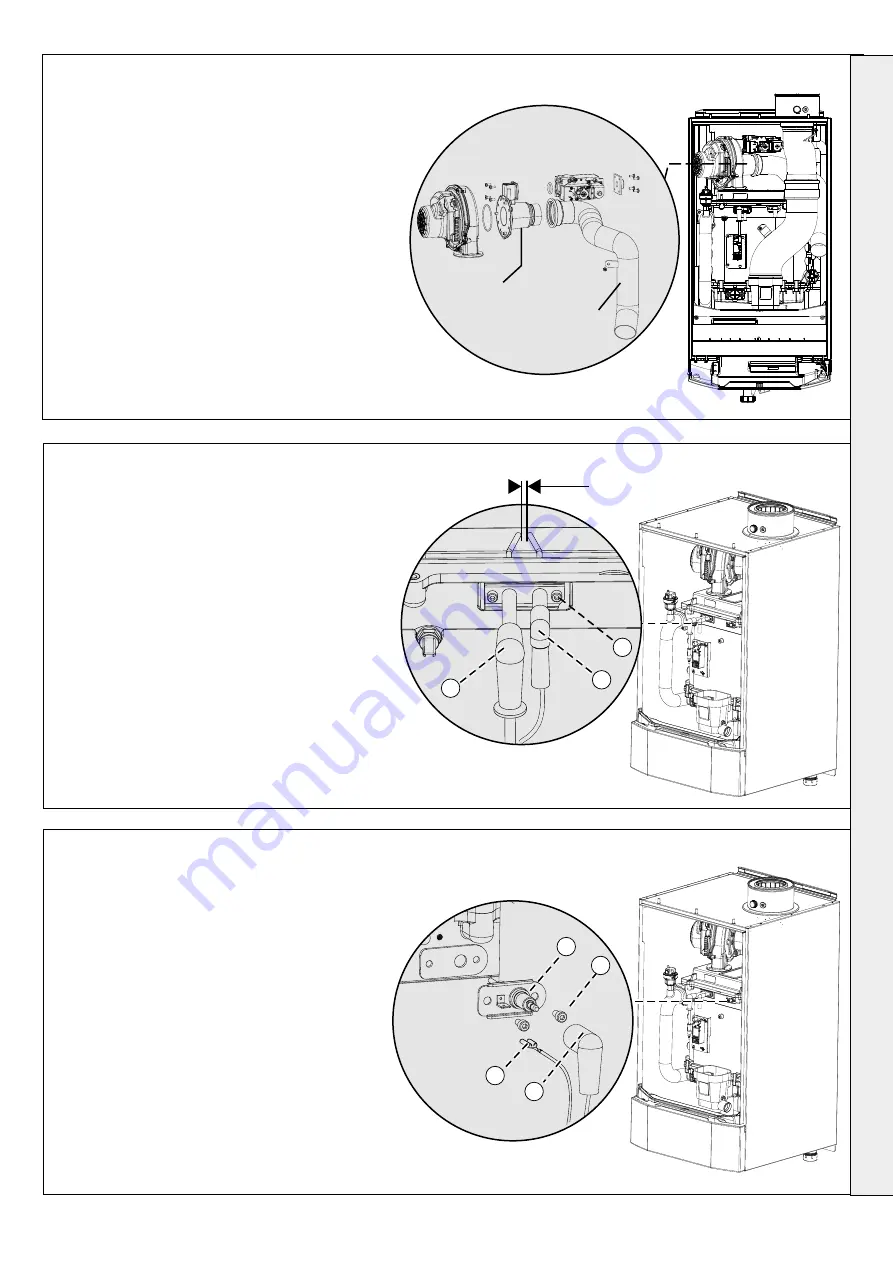

REMOVAL OF VENTURI / AIR INLET DAMPER

1. Refer to Section 2.33.

2. Remove the front panel. Refer to Section 3.2.

3. Remove the flue manifold complete with seal and

remove the air damper Section (all but the 150kW

have a fixing screw) refer to Section 3.4. If the air

inlet damper is damaged go to points 6-8.

4. Remove the fan and gas assembly. Refer to Section

3.3.

5. Remove venturi from fan and gas valve. Refer to

Sections 3.9 & 3.10.

6. Replace with new venturi/ air inlet damper if

necessary ensuring the gas orifice is fitted and seal

is replaced.

7. Reassemble in reverse order replacing all gaskets.

8. Check the operation of the boiler. Refer to Section

2.33

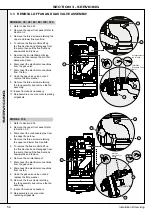

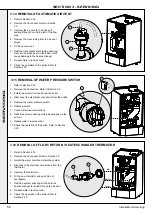

3.13 REMOVAL OF DETECTION ELECTRODE

1. Refer to Section 2.33.

2. Remove the front panel. Refer to Section 3.2.

3. Pull off the spark lead and earth connection.

4. Remove the two retaining cap head screws.

5. Pull out the electrode and pull off the old gasket.

6. Replace with new electrode and gasket supplied

checking the spark gap is 3.5mm ±1.

7. Reassemble in reverse order.

8. Check the operation of the boiler (Refer to

Section 2.33.

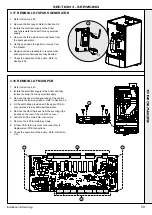

1. Refer to Section 2.33.

2. Remove the front panel. Refer to Section 3.2.

3. Pull off the detection lead and earth connection.

4. Remove the two retaining cap head screws.

5. Pull out the electrode and pull off the old gasket.

6. Replace with new electrode and gasket ensuring

correct electrode is fitted.

7. Reassemble in reverse order.

8. Check the operation of the boiler. Refer to

Section 2.33.

3.12 REMOVAL OF IGNITION ELECTRODE

3.5mm ±1

3

5

4

3

3

5

4

Air inlet damper

Venturi

57

Installation & Servicing

SECTION 3 - SERVICING

SER

VICING

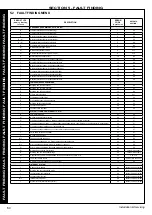

Summary of Contents for EVOMAX 2 30

Page 4: ...4 Installation Servicing...

Page 75: ...75 Installation Servicing NOTES...

Page 76: ...76 Installation Servicing NOTES...

Page 77: ...77 Installation Servicing NOTES...

Page 78: ...78 Installation Servicing NOTES...