37

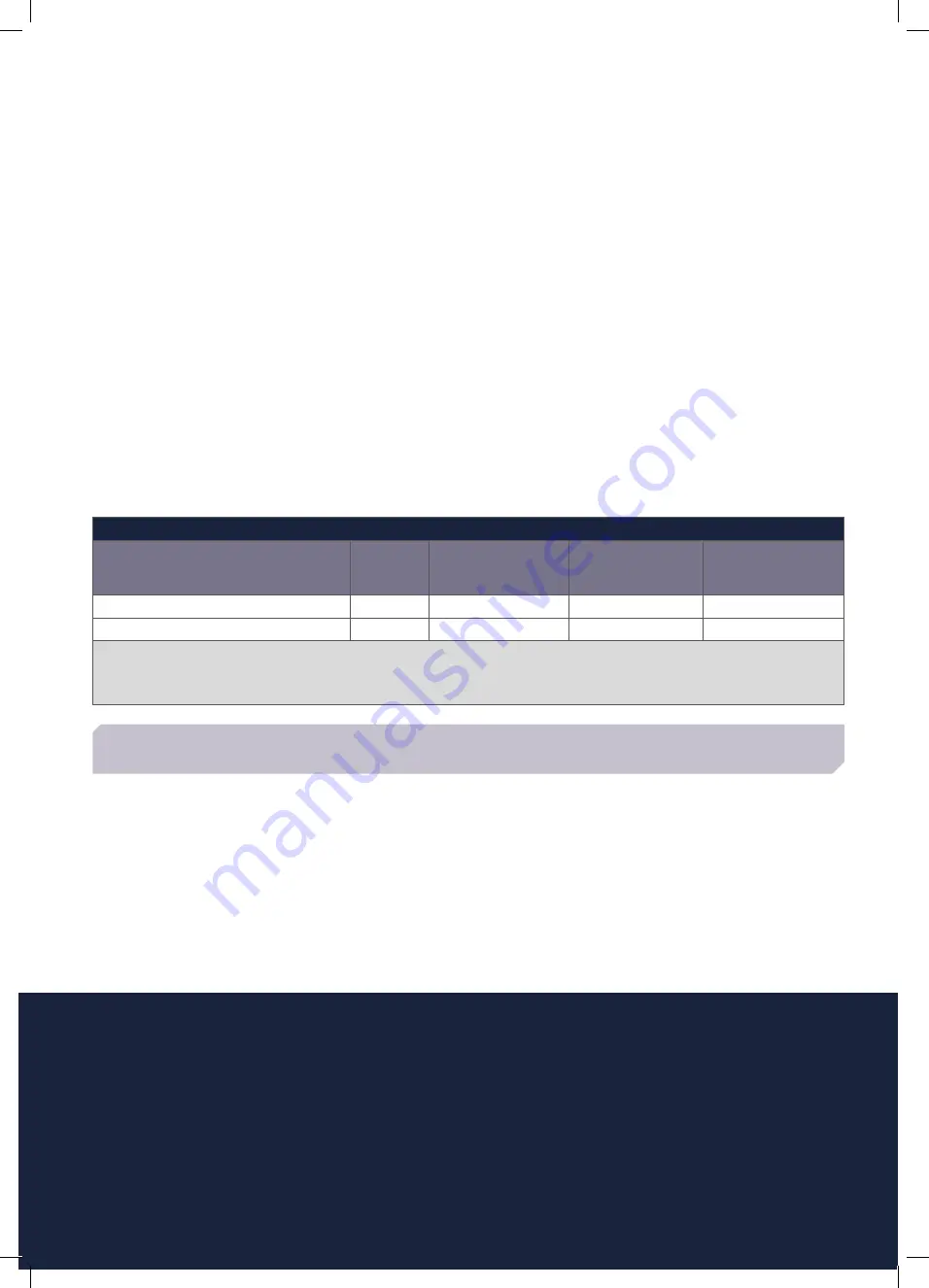

MINIMUM QUANTITY OF MECHANICAL VENTILATION

Mechanical ventilation m

³

/hr per kW net heat input

(A) Min

inlet air

m

³

/hr

(B) Difference

between inlet and

extract air

†

m

³

/hr

Summer usage

††

greater than 50%

up to 75%

Summer usage

††

greater than 75%

up to 100%

Boiler(s) with draught diverter

2.8

2.07

±

0.18

+0.72

+1.44

Boiler(s) without draught diverter†††

2.6

1.35

±

0.18

+0.72

+1.44

†inlet air minus ventilation 2.8 - 2.07 = 0.73m

³

/hr

††For boilers in use for more than 50% of the time during the summer months, additional mechanical ventilation needs to be

added to those columns A and B

††† with or without draught stabilisers

• High level ventilation openings shall be located as high as is reasonably practicable and preferably within 15% of the

building height from the ceiling.

• Low level ventilation openings shall be within 1m of the floor for Natural Gas and within 250mm of the floor for LPG.

• For LPG it is preferable that low level ventilation openings are located at floor level.

• Ventilation to an internal space is not generally recommended unless a Risk Assessment has been completed.

• The air supplied for boiler room ventilation shall be such that the maximum temperature within the boiler house is:

• 25

˚

C at floor level (or 100mm above floor level)

• 32

˚

C at mid level (1.5 m above floor level)

• 40

˚

C at ceiling level (or 100mm below ceiling level)

MECHANICAL VENTILATION

• Mechanical ventilation can be a combination of mechanical inlet and outlet or mechanical inlet and natural

ventilation outlet.

• The fans shall be selected and controlled so as to not cause a negative pressure (relative to the outside atmosphere)

developing in the boiler room.

• Interlocked to the gas appliance.

IMPORTANT

The application of any other treatment to this product may

render the guarantee of Ideal Boilers Invalid.

Ideal Boilers recommend Water Treatment in accordance with

the Benchmark Guidance Notes on Water Treatment in Central

Heating Systems.

If water treatment is used Ideal Boilers recommend only the

use of Scalemaster Gold 100, Fernox, MB-1, Adey MC1,

Sentinel-X100, CALMAG CM100 inhibitors and associated water

treatment products, which must be used in accordance with

the manufacturers’ instructions.

NOTES

1.

It is most important that the correct concentration of the

water treatment products is maintained in accordance with the

manufacturers’ instructions.

2.

If the boiler is installed in an existing system any unsuitable

additives MUST be removed by thorough cleansing. BS

7593:2006 details the steps necessary to clean a domestic

heating system.

3.

In hard water areas, treatment to prevent lime scale may be

necessary - however the use of artificially softened water is

NOT permitted.

4.

Under no circumstances should the boiler be fired before

the system has been thoroughly flushed.

FOR FURTHER INFORMATION CONTACT:

Fernox Alent plc

Forsyth Road, Sheerwater, Woking, Surrey

GU21 5RZ

Tel: +44 (0) 870 601 5000

Sentinel Performance Solutions

7560 Daresbury Park

Daresbury, Warrington

Cheshire

WA4 4BS

Tel: 0800 389 4670

www.sentinelprotects.com

Scalemaster Water

Treatment Products

Emerald Way, Stone, Staffordshire

ST15 0SR

Tel: 01785 811636

Calmag Ltd.

Riverview Buildings

Bradford Road, Riddlesden,

Keighley, West Yorkshire

BD20 5JH

Tel: +44 (0) 1535 210 320

Adey Professional

Heating Solutions

Gloucester Road,

Cheltenham GL51 8NR

Tel: +44 (0) 1242 546700

WATER TREATMENT

Summary of Contents for EVOMAX 2 30

Page 1: ...EVOMAX 2 CONDENSING BOILER PRODUCT FLUE GUIDE...

Page 5: ...5...

Page 12: ...12 EVOMAX 2 CASCADE 30 900kW...

Page 18: ...18 EVOMAX 2 FLUE OPTIONS...

Page 19: ...19...

Page 41: ...41...

Page 43: ...43 NOTES...