18

xtra

-

Installation & Servicing

INSTALLATION

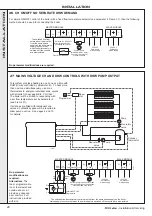

REAR VIEW

RETURN

FLOW

(Must be

connected

opposite side

to flow

connection)

(Must be

connected

opposite side

to return

connection)

im8482

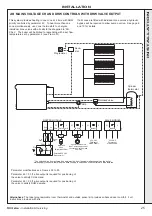

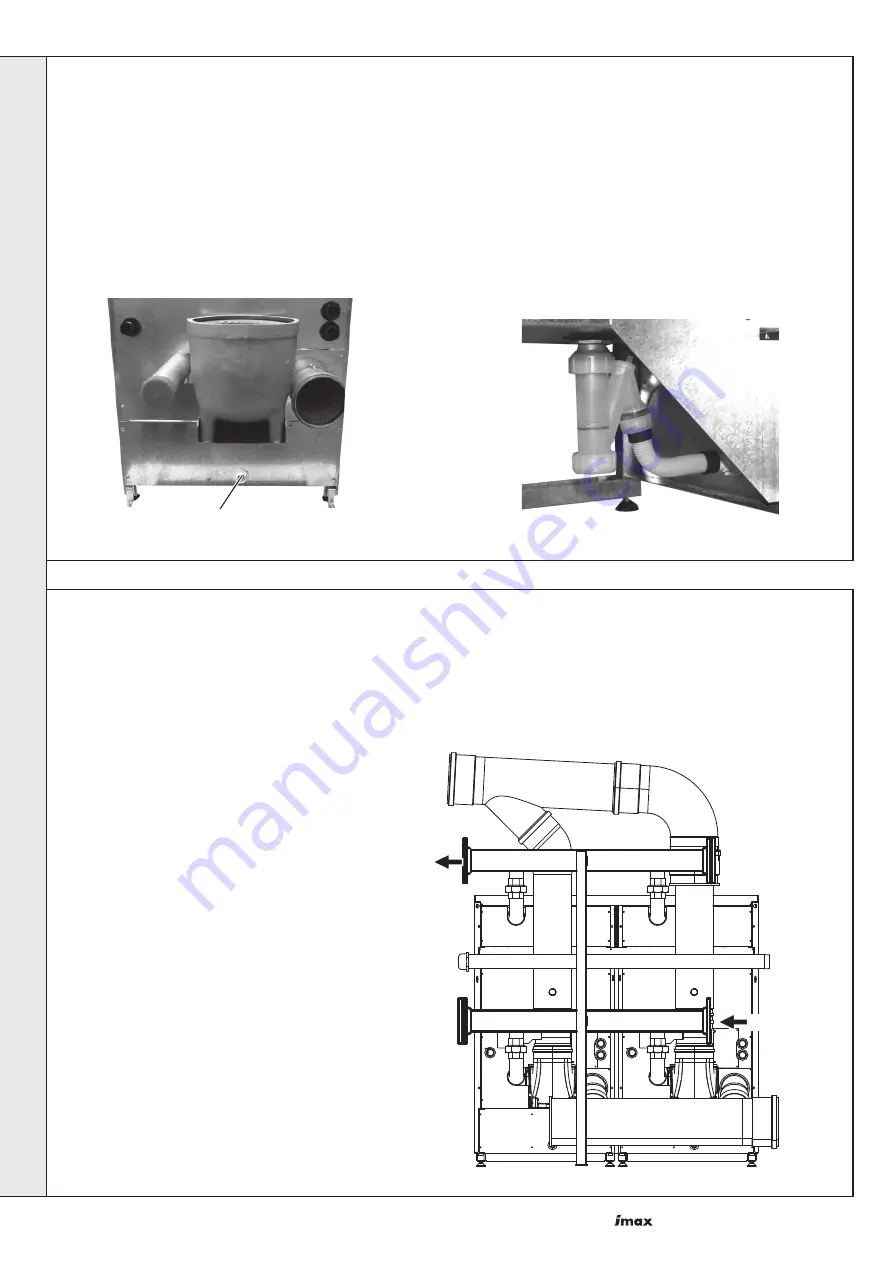

13 CONDENSATE DRAIN (Slave and Master)

A condensate drain must be connected to the

condensate bulk head connector on the back of each

module and then connected to a drainage point,

preferably within the building.

The pipe size from the condensate connector on the

lower rear panel is 21.5mm.

The routing of the drain must be made to allow a

minimum fall of 1 in 20 away from the boiler, throughout

its length.

14 BOILER WATER CONNECTIONS

The boiler flow and return pipes are terminated with 2 x R2" BSP male

connections at the rear of the appliance. Water returning from the system

should be connected to a lower header pipe, with the flow water connection

coming from a top header pipe. An optional pre-

fabricated header pipe kit is available.

Refer to Frames 1 and 2 for dimensional

positions.

All flow and return pipework must be

independently supported.

Plastic plugs fitted on the open ends of the flow

and return pipes must be removed before

connecting the system pipework.

An air vent must be provided immediately after the

flow connection.

If installing the boiler onto an existing system it is

strongly recommended that the system be

thoroughly flushed before connecting the boiler.

When connecting to a new system it is still

important to flush the whole system in accordance

with the relevant standards.

Condensate Bulkhead Connector

If the vertical flue header is specified the flue manifold

condensate drain connection must also be connected in the

same manner.

IMPORTANT.

Any external runs must be kept to a minimum

and insulated. This is to avoid freezing in cold weather

causing blocking.

All pipework and fittings in the condensate drain system

must be made of plastic. No other materials may be used.

Note.

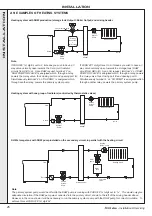

Connection to the boilers using manifolds must

use a reverse return principle to ensure equal flow

distribution through both of the modules, see

example below.

Connection of opposing flow and return points can

be made either on the LH side or RH side,

dependent upon the particular needs of the boiler

installation.

INST

ALLA

TION