19

xtra

-

Installation & Servicing

INSTALLATION

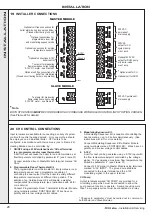

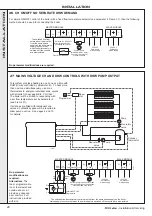

18 INSTALLING THE MAINS AND CONTROL WIRING (MASTER AND SLAVE MODULES)

1.

Route all 230V circuits in at the rear, through

conduit no. 1 on both Master and Slave

Modules.

2.

Route all low voltage remote sensor/control

cables for the master module through conduit

no. 2.

3.

Secure the cables with the cable clamps

provided on the main controls panel.

2

1

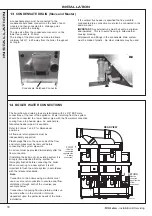

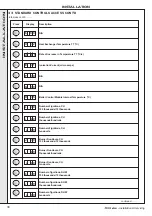

16 GAS CONNECTIONS

The boiler gas supply pipe is terminated in 2 x R1" BSP male

taper connections on the left-hand sides of the modules.

A gas header kit is available to combine the inlet connections

to a 2" manifold.

All gas supply pipework must be independently supported.

A minimum working gas pressure of 15mbar (6" w.g.) must

be available at the boiler inlet with the boiler firing.

Fit a gas supply pipe NOT LESS THAN 2" BSP to the boiler.

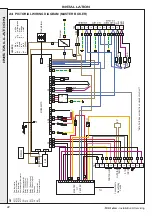

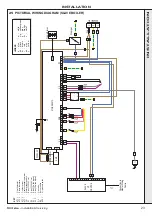

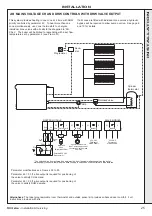

17 ELECTRICAL CONNECTIONS

Warning

. This appliance MUST be efficiently earthed.

A mains supply of 230V 50Hz is required to be fitted to both the

Master and Slave Modules (see terminals marked 'Mains In'

Frame 19). External controls should NOT be wired in series

with these mains inputs. Controlling the boiler in this way will

prevent the pump over-run sequence and may cause damage

to the modules. The supply wiring MUST be suitable for mains

voltage. Wiring should be 3 core PVC insulated cable NOT

LESS than 0.75mm

2

(24 x 0.2 mm) and to BS. 6500, Table 16.

The fuse rating should be 7A.

Wiring external to the boiler MUST be in accordance with the

current I.E.E. (BS7671) wiring Regulations and any local

regulations. For Ireland reference should be made to the

current ETCI rules for electrical installations.

Connection should be made in a way that allows complete

isolation of the electrical supply - such as a double pole

switch, having a 3mm (1/8") contact separation in both poles,

or a plug and unswitched socket serving only the boiler and

system controls. The means of isolation must be accessible

to the user after installation.

When making mains electrical connections to the modules it

is important that the wires are prepared in such a way that the

earth conductor is longer than the current carrying conductors,

such that if the cord anchorage should slip the current carrying

conductors become taut before the earthing conductor.

WARNING. Sensor cables must be separated from cables in

the 230V circuit. For this purpose three conduits are

provided. Refer to Frame 19 for terminal strip connections.

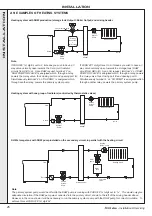

15 FROST PROTECTION

The boiler has built into its control system the facility to protect

the boiler only against freezing.

If the boiler flow temperature T

1

, falls below 7

o

C the pump will

be activated without the boiler firing.

If the flow temperature falls below 5

o

C the boiler will fire until

the flow temperature exceeds 10

o

C. The pump will stay

running for a further 5 minutes.

Central heating systems fitted wholly inside the building do

not normally require frost protection as the building acts as a

'storage heater' and can normally be left at least 24 hours

without frost damage. However, if parts of the pipework run

outside the building or if the boiler will be left off for more than

a day or so, then frost protection for the system is

recommended.

INST

ALLA

TION