20

xtra

-

Installation & Servicing

INSTALLATION

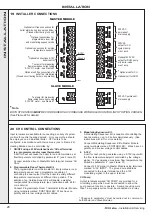

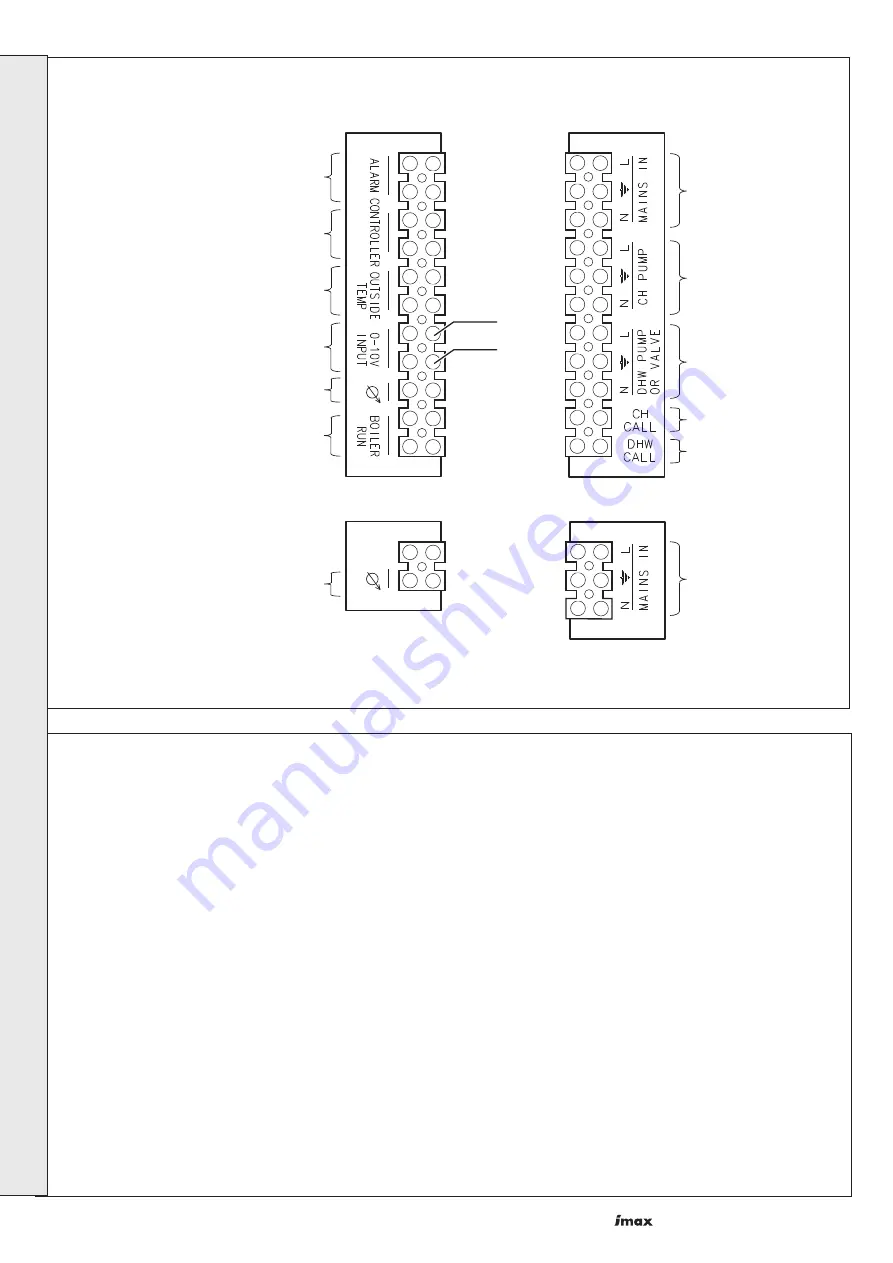

19 INSTALLER CONNECTIONS

230V AC

permanent

mains supply

230V AC permanent

mains supply

230V AC

output for CH

system pump.

max 1 amp

Optional 230V AC

output for DHW pump

or divertor valve.

max 1 amp.

*

Optional call for CH

Optional call for DHW

im8483

MASTER MODULE

SLAVE MODULE

*

Optional connections for

programmable room stat

and modulating sequencer kits

Optional volt free connections for

boiler alarm during lock out condition.

(Closed circuit during lock out)

Optional connections for outside

temperature sensor kit

*

Optional connections 0-10V

boiler control

Test point for measuring

flame ionisation current using

0-10V DC meter - see Frame 61

Test point for measuring

flame ionisation current using

0-10V DC meter - see Frame 61

Optional volt free connections for

boiler 'run' inidication

(Closed circuit during burner on operation)

0-10V

Ground

*

Note.

BOTH OT CENTERS

MUST

BE CONFIGURED IN ACCORDANCE WITH BOILER CONTROL INPUT OPTION CHOSEN.

(See Frame 22 for details)

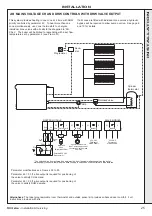

Input terminals are available for connecting a variety of system

controls for central heating demand. Only one method should

be employed on an individual boiler. OT Centers to be

configured in accordance with choice mode (see to Frame 22).

Heating demand can be controlled by:

1. ON/OFF using a 230V switched live to 'CH call' terminal.

(e.g. programmer and/or room thermostat).

A call for heat will cause the boiler to run and maintain a set

flow temperature controlled by parameter 4* (see Frame 31).

Connect switched live to Master Module terminal marked 'CH

CALL'.

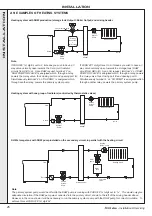

2. Programmable Room Thermostat Kit.

The programmable room thermostat kit incorporates a room

temperature sensor and a programmer capable of

controlling the heat output from the boiler to satisfy different

temperature requirements at different time periods. The

addition of an Outside Sensor Kit will enable a weather

compensated flow temperature (see Instructions with kit for

more details).

Connect Programmable Room Thermostat to Master Module

using terminals marked 'CONTROLLER'. Wires have no

polarity and are low voltage control cables.

3. Modulating Sequencer Kit.

A Modulating Sequencer Kit is capable of controlling the

heat demand on up to 5 boilers simultaneously. (See

instructions with kit for more details.)

Connect Modulating Sequencer Kit to Master Module

using terminals marked 'CONTROLLER'. Wires have no

polarity and are low voltage control cables.

4. 0-10V

A call for heat can be generated using a 0-10V input with

the flow temperature setpoint controlled by the voltage

signal. 10V generates a maximum flow temperature top

limited by parameter 4* (see Frame 31).

Connect 0-10V signal to Master Module using terminals

marked '0-10V INPUT'. The ground wire should be

connected to the lower terminal and the 0-10V

modulating signal to the upper terminal.

CH Pump

Output terminals marked 'CH PUMP' are provided for a

circulating pump which must be connected to allow the

pump overrun function to operate. A pump requiring more

than 1 amp supply current must be connected via a relay.

20 CH CONTROL CONNECTIONS

* Changes to parameter 4 must be carried out in common to

both Master and Slave Modules.

INST

ALLA

TION