4

xtra

-

Installation & Servicing

GENERAL

INTRODUCTION

The

xtra

boilers are fully automatically controlled, floor

standing, fanned, super efficient condensing appliances.

The imax xtra comprises of 2 modules, Master and Slave.

The comprehensive boiler controls built into the appliance

include:

-

0-10V Boiler control input

-

Volt free 'alarm' contacts (lockout)

-

Volt free 'boiler run' contacts

-

Burner hours run meters

-

System temperature indication

The boilers can draw their combustion air from the room or via

ducting from outside.

Through a sophisticated control system combined with premix

burner technology and an aluminium heat exchanger, the boilers

are capable of high operating efficiencies of 93% (gross) and low

emissions.

These boilers are certified to meet the requirements of the EC

Gas Appliance Directive, Boiler Efficiency Directive, EMC and Low

Voltage Directive.

OPTIONAL EXTRA KITS

•

Modulating Sequencer

- DHW Sensor

- Room Sensor

•

Programmable Room Stat

•

Outside Sensor

(only suitable for use in conjunction with Prog. Room Stat)

•

Water and Gas Header Pack

•

RS Air Duct Connector

(F320 and F400 only)

•

Horizontal Flue Header

*

•

Vertical Flue Header

*

* A flue header kit (horizontal or vertical) must be fitted to boiler.

SAFETY

Current Gas Safety (Installation and Use) Regulations or rules in

force

The appliance is suitable only for installation in GB and IE and

should be installed in accordance with the rules in force.

In GB, the installation must be carried out by a CORGI Registered

Installer or in IE by a competent person. It must be carried out in

accordance with the relevant requirements of the:

•

Gas Safety (Installation and Use) Regulations

•

The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland), Building

Regulations (Northern Ireland).

•

The Water Fittings Regulations or Water byelaws in Scotland.

•

The Current I.E.E. Wiring Regulations.

Where no specific instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a Competent Person

and installed in accordance with the current Building Regulations

and reference should be made to the current ETCI rules for

electrical installation.

The boilers have been tested by Gastec and conform to EN483

and EN677 for use with Natural Gas.

Detailed recommendations are contained in the following

Standards and Codes of Practice:

BS. 5854

Flue and flue Structures in Buildings.

BS. 6644

Installation of gas fired hot water boilers of rated

inputs between 70kW and 1.8MW (net) (2nd and

3rd family gases).

BS. 6880

Low temperature hot water heating systems of

output greater than 45kW.

Part 1

Fundamental and design considerations.

Part 2

Selection of equipment.

Part 3

Installation, commissioning and maintenance.

IGE/UP/1

Soundness testing and purging of industrial and

commercial gas installations.

IGE/UP/2

Gas installation pipework, boosters and

compressors on industrial and commercial

premises.

IGE/UP/10

Installation of gas appliances in industrial and

commercial premises.

SAFE HANDLING OF SUBSTANCES

No asbestos, mercury or CFCs are included in any part of the

boiler or its manufacture.

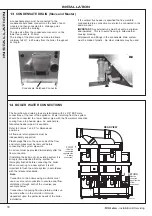

FOUNDATION / LOCATION OF BOILER

The boiler must stand on a floor which must be flat, level and of a

suitable load bearing capacity to support the weight of the boiler

(when filled with water) and any ancillary equipment.

Ideally the boiler should be placed on a plinth exceeding the plan

area of the boiler by 75mm on each side and at least 100mm high.

The boiler must not be fitted outside.

GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an adequate

supply of gas. An existing service pipe must NOT be used without

prior consultation with the local gas supplier.

A gas meter can only be connected by the local gas supplier or by a

registered CORGI engineer or in IE by a competent person.

An existing meter should be checked, preferably by the gas

supplier, to ensure that the meter is adequate to deal with the rate

of gas supply required. A minimum working gas pressure of

15mbar MUST be available at the boiler inlet for Natural gas.

Do not use pipes of smaller size than the boiler inlet gas

connection.

The complete installation MUST be tested for gas soundness and

purged in accordance with the appropriate standards.

Gas Boosters

A gas booster is required if the gas pressure available at the boiler

is lower than that required by the boiler manufacturer to attain the

flow rate for maximum burner input rating.

Location of the booster requires careful consideration but should

preferably be closer to the burner rather than the gas meter.

Ventilation should also be considered to ensure ambient

temperature do not exceed designed recommendations. Further

guidance is provided in IGE/UP/2.