50

xtra

-

Installation & Servicing

SERVICING

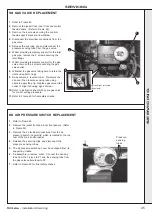

69 MOTORISED DAMPER MOTOR REPLACEMENT

70 AIR DAMPER REPLACEMENT

1.

Refer to Frame 49.

2.

Loosen 2 securing screws from motor

cover and remove cover.

3.

Disconnect electrical connections.

4.

Remove 2 x M5 nuts and washers

located behind mounting plate and

remove motor.

5.

Replace with new motor.

6.

Re-assemble and re-wire in reverse

order.

7.

Refer to Frame 49 for final safety

checks.

2

3

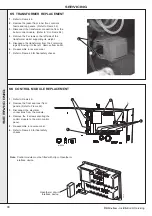

1.

Refer to Frame 49.

2.

Remove front and inner front panels (Refer to

Frame 52).

3.

If replacing Slave Module air damper first remove

boiler LHS panel (Refer to Frame 52).

4.

Remove 4 x M6 nuts, bolts and washers locating

air duct flange to venturi assembly on the module

that the air damper is to be removed.

5.

Remove 2 x M5 nuts retaining air duct lower

support bracket on module that the air damper is

to be removed. Remove bracket.

6.

Pull air duct assembly forward and pull air duct

flanges out of automatic air duct inlet and outlet

connections.

Inspection and Replacement:

7.

Check butterfly flaps within air damper move

freely without sticking. Remove any dust/debris

with a soft brush. Check integrity of O-ring seals

within flange connectors.

8.

Re-fit damper ensuring it is orientated such that

the butterfly flaps open inwards towards the front

of the boiler module. Also ensure inspection

window faces uppermost.

9.

Re-fit ductwork in reverse order to disassembly.

Check venturi flange O-ring seal is in good

condition and correctly located in its groove

during assembly.

10.

Refer to Frame 49 for final safety checks.

4

9

5

SER

VICING