7

Falcon GTE -

Installation & Servicing

GENERAL

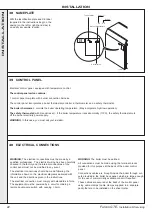

3

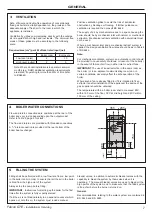

VENTILATION

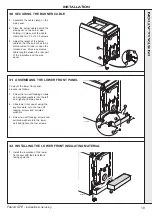

Safe, efficient and trouble-free operation of conventionally

flued gas boilers is vitally dependent on the provision of an

adequate supply of fresh air to the room in which the

appliance is installed.

Ventilation by grilles communicating directly with the outside

air is required at both high and low levels. The minimum free

areas of these grilles must be according to the following

scale:

5

FILLING THE SYSTEM

Position ventilation grilles to avoid the risk of accidental

obstruction by blockage or flooding. If further guidance on

ventilation is required then consult BS 6644.

The supply of air by mechanical means to a space housing the

boiler should be by mechanical inlet with natural or mechanical

extraction. Mechanical extract ventilation with natural inlet must

not be used.

Where a mechanical inlet and a mechanical extract system is

applied, the design ventilation flow rates should be as in Table 4

of BS 6644.

Note.

For mechanical ventilation systems an automatic control should

be provided to cause safety shutdown or lockout of the boiler(s)

in the event of failure of air flow in either inlet or extract fans.

IMPORTANT.

The use of an extractor fan in the same room as

the boiler (or in an adjacent communicating room) can, in

certain conditions, adversely affect the safe operation of the

boiler.

Where such a fan is already fitted (or if it is intended to fit an

extractor fan after installation of the appliance) the advice of the

gas supplier should be obtained.

The temperature within a boiler room shall not exceed 25

o

C

within 100 mm of the floor, 32

o

C at mid height and 40

o

C within

100 mm of the ceiling.

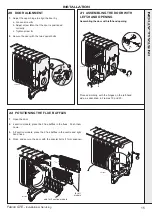

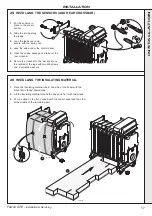

Filling shall be performed with a low flow rate from a low point

in the boiler room in order to ensure that all the air in the boiler

is bled from the high point of the system.

Always stop the pump before filling.

IMPORTANT.

Instructions for starting up the boiler for the first

time after the system is fully or partly drained:

If all the air is not bled naturally to an expansion vessel which

opens out onto the air, the system must include manual

bleeder valves, in addition to automatic bleeder valves with the

capability to bleed the system by themselves when it is

operating. The manual bleeder valves are used to bleed all the

high points of the system and to make sure that the filled system

is free of air before the burner is turned on.

General

Recommendations relating to the water system are contained in

BS. 5449 and BS. 6880.

4

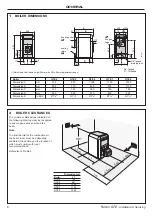

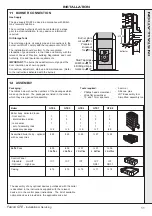

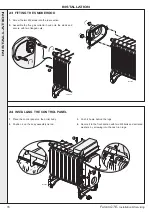

BOILER WATER CONNECTIONS

Flow and return connections are positioned at the rear of the

boiler and vary in size depending upon the output model.

Refer to Table 2, page 2 for sizes.

The flow and returns are provided with threaded connections.

A

3

/

4

" drain connection is provided at the rear bottom of the

boiler heat exchanger.

189

188

753

355

205

165

=

=

fal5921

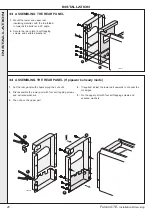

Required area (cm

2

) per kW of total rated input (net)

Boiler room

Enclosure

Low level (inlet)

4

10

High level (outlet)

2

5

Note: Where a boiler installation is to operate in summer

months (e.g. DHW) additional ventilation requirements

are stated, if operating for more than 50% of time (refer

to BS6644).