8

Falcon GTE -

Installation & Servicing

GENERAL

7

SEALED (PRESSURISED) SYSTEMS

6

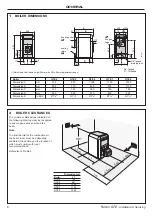

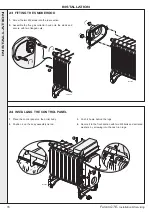

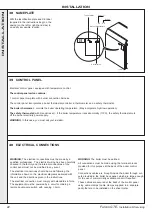

OPEN VENTED SYSTEM REQUIREMENTS - minimum static head requirements

The Falcon GTE boiler has a minimum static head requirement of

5.0 metres (16.5 feet approx.) depending on the particular

characteristics of the system design (see diagram). The information

provided is based on the following assumptions.

1.

An open vent/safety pipe connection is made immediately after

the flow connection.

2.

A cold feed/expansion pipe connection is made to the system

return pipe within 0.75m of the boiler return connection.

3.

The maximum flow rate through the boiler is based on a

temperature difference of 11

o

C (20

o

F) at full boiler output with the

circulating pump positioned in the flow of the system.

4.

The boiler is at the highest point of the system. Systems

designed to rise above the flow connections will, of course,

automatically require a minimum static head higher than shown.

5.

The position of the open vent/safety pipe above the expansion

cistern water level is given as a guide only. The final position will

depend upon particular characteristics of the system. Pumping

over of water into the expansion cistern should be avoided.

6.

Both open vent/safety pipe and cold feed/expansion pipes must

be of adequate diameter to suit the output of the boiler (see table

below).

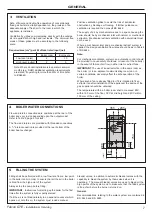

Working pressure 4 bar maximum.

Particular reference should be made to BS. 6644: Section 2;

Subsection 11 and Guidance note PM5 "Automatically

controlled steam and hot water boilers" published by the

Health and Safety Executive.

The information and guidance given below is not intended to

override any requirements of either of the above publications

or the requirements of the local authority, as or water

undertakings.

In general commercial closed pressurised systems are

provided with either manual or automatic water make up.

In both instances it will be necessary to fit automatic controls

intended to protect the boiler, circulating system and ancillary

equipment by shutting down the boiler plant if a potentially

hazardous situation should arise.

Examples of such situations are low water level and operating

pressure or excessive pressure within the system.

Depending on circumstances, controls will need to be either

manual or automatic reset. In the event of a shutdown both

visual and audible alarms may be necessary.

Open vent

safety pipe

750mm

Cold feed/

expansion pipe

H = 5.0m

To

pump

FLOW

RETURN

Shunt pump

(if required)

Note: Height, H, MUST be

increased if necessary to

comply with the min.

head required by the

pump manufacturer

BOILER

This diagram does not show safety valves & water

flow switches etc necessary for safe operation

Expansion

cistern

FAL7405

Boiler Output kW

Open Vent (mm)

Cold Feed (mm)

30 to 60

25

20

60 to 150

32

25

Expansion vessels used must comply with BS. 4814 and must

be sized on the basis of the total system volume and initial

charge pressure.

Initial minimum charge pressure should not be less than 0.5

bar (7.2psi) and must take account of the static head and

specification of the pressurising equipment. The maximum

water temperatures permissible at the point of minimum

pressure in the system are specified in Guidance Note PM5.

When make up water is not provided automatically it will be

necessary to fit controls which shut down the plant in the event

of the maximum system pressure approaching to within

0.35bar (5psi) of the safety valve setting.

other British Standards applicable to commercial sealed

systems are:

BS. 6880: Part 2

BS. 1212

BS. 6281: Part 1

BS. 6282: Part 1

BS. 6283: Part 4