19

FP14KC-X

JAN 2023

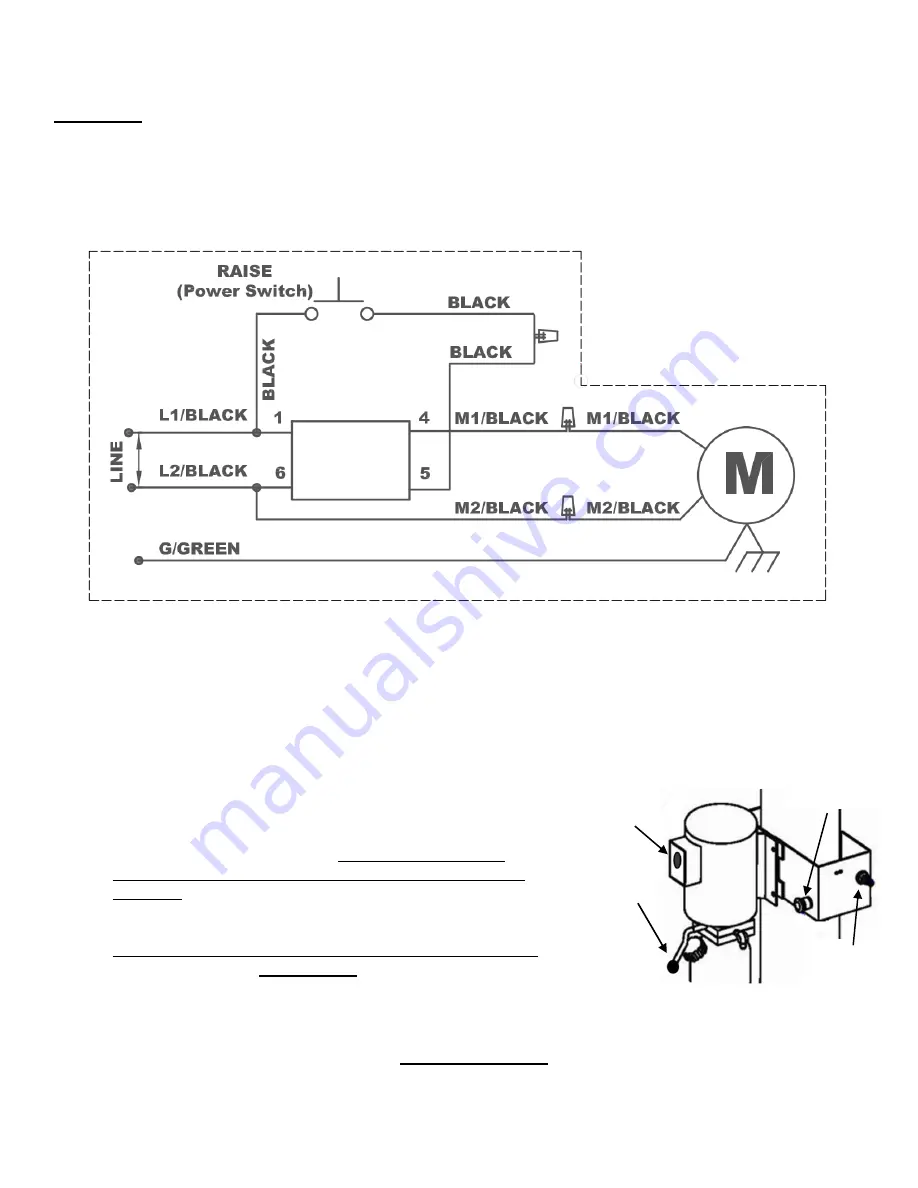

Step 7: Power Unit Electrical Connection

WARNING: Electrical Wiring must comply with local code. Use separate circuit for each power

unit and protect each circuit with time delay fuse. For 208V-230V single phase, use 20 amp fuse.

1)

Have a Certified Electrician make the electrical connection from power supply to the power unit. Use

separate circuit for each power unit,

Fig. 29

.

208 - 230VAC, 1PH, 60Hz

Fig. 29

CAUTION!

Never operate the Power Unit in-line voltage less than 208VAC, as motor damage

may occur. Never operate Power Unit with no hydraulic oil, as pump damage may occur.

Step 8: Cycle Testing & Bleeding Hydraulics

CAUTION!

DO NOT place Vehicle on Lift for the following Test Steps.

1) To Cycle Test Lift

, first turn on 220VAC electrical supply

to Power unit and connect shop air to Quick Disconnect

Air Fitting on Control Bracket. Ensure shop air supply

to Air Fitting is between 90 - 115 PSI for proper Latch

operation,

Fig. 30

.

2)

Press the START/UP button on the motor to slightly raise lift, but

only until the steel cables are tensioned in each Post, then release

START/UP button.

IMPORTANT

:

Inspect & confirm the steel cables

are properly engaged in grooves of all cable pulleys

-

Ref. Figs 7 & 8

.

Fig. 30

3) To Bleed Hydraulics

, cycle the lift

‘Up & Down’ fully 2 to 3 times to bleed (remove air) from the hydraulic

system or until the lift lowers smoothly.

OPERATION NOTE: To Lower Lift press the Manual Release

Lever to release hydraulic pressure, while at the same time pressing the ‘Red’ Button on the Air

Valve to release latches allowing lift to lower without engaging Latch Racks,

Fig 30

.

START / UP

Button

Manual

Release Lever

Shop Supply

Air Fitting

Air Valve

Button