INSTALLATION

21

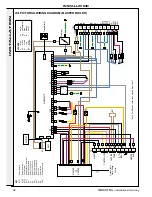

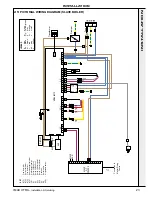

IMAX XTRA -

Installation & Servicing

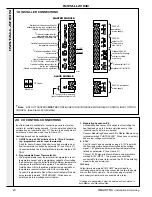

S1

S2

Rear of OT Center

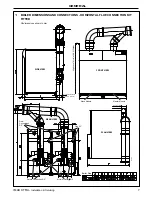

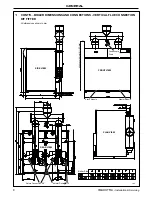

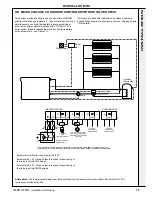

23 FITTING OT CENTER

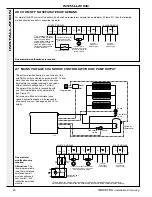

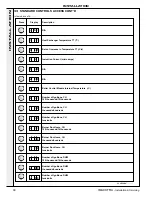

22 OT CENTER CONFIGURATION

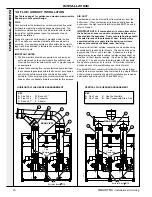

The OT Centers on each module are factory pre-set as master

and slave units for CH ON/OFF call for heat.

To check the settings or to configure for alternative control

options remove the OT Center and set switches "S1 and "S2"

according to the tables below (See Frame 67 for details of how

to remove and replace OT Centers).

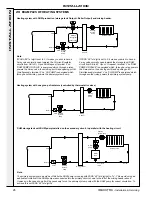

If the boiler is providing both CH and DHW, and the CH circuit

is to operate for periods at a reduced temperature (i.e. weather

compensated), then it is necessary to differentiate between CH

and DHW heat demands. For this purpose a DHW demand

can be placed on the boiler using the method shown below.

A demand for DHW has priority over CH by parameter 43 (see

Frame 38).

A call for DHW will cause the boiler to run and maintain a set

flow temperature of 80

o

C.

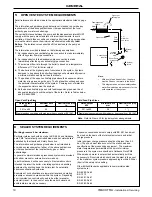

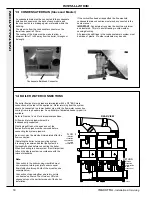

21 DHW CONTROLS CONNECTIONS

DHW heat demand can be controlled by:

1. ON/OFF using a 230V switched to live 'DHW

call' terminal (e.g. a cylinder thermostat and/ or

programmer).

A call for heat will cause the boiler to run and maintain a set

flow temperature of 80

o

C.

Output terminals are provided for a DHW pump or valve. This

output can be used to control the diversion of flow to the DHW

circuit. A pump or valve requiring more than 1 amp supply

current must be connected via a relay.

* Changes to parameter 4 must be carried out in common to

both Master and Slave Modules.

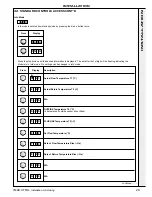

Position S2 Function

1

Master - Module

2

Slave Module

Position S1 Function

1 N/A

2 N/A

3

Opentherm programmable

room stat or sequencer kit

4

CH ON-OFF call for heat

5

0 to 10 V Input

Note.

Both OT Centers (Master and Slave Modules) must

be configured similarly.

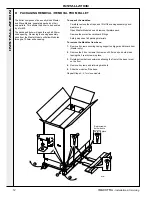

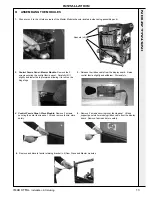

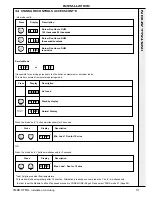

1.

Locate the communication lead attached to the OT Center on the Master Module.

2.

Route cable through grommet, and across behind control panels and back out

through grommet.

3

3

2

3.

Plug remaining end into either

socket on Slave Module OT

Center.

INST

ALLA

TION