SERVICING

39

IMAX XTRA -

Installation & Servicing

48 HANDING OVER

ROUTINE OPERATION

Full instructions covering routine lighting and operation of the

boiler are given on the Lighting and Operation Instruction Label

located behind the lower front door.

Draw the attention of the boiler owner or his representative to

the Lighting and Operating Instruction Label. Give a practical

demonstration of the lighting and shutting down of the boiler.

Describe the function of the boiler and system controls and

show how they are adjusted and used.

Hand these Installation and Servicing Instructions/User's

Instructions and Log book to the customer and request him

to keep them in a safe place for ready reference. For IE, it is

necessary to complete a "Declaration of Conformity" to indicate

compliance to the appropriate standard.

IMPORTANT.

Point out to the owner that the boiler must have regular

maintenance and cleaning, at least annually, in order to ensure

reliable and efficient operation. Regular attention will also

prolong the life of the boiler and should preferably be performed

at the end of the heating season.

After servicing, complete the service section of the log book and

return to the owner or their representative.

Recommend that a contract for this work should be made with

the regional gas authority or a Gas Safe Registered Engineer. In

IE servicing work must be carried out by a competent person.

49 SAFETY

It is the law that any service work must be carried out by a Gas

Safe Registered Engineer. In IE service work must be carried out

by a competent person.

WARNING

. Always turn off the gas supply at the gas service

cock, and switch off and disconnect the electricity supply to

the appliance and any external controls before servicing or

replacing components.

NOTE.

When the burner switch is in the off position the boiler

control module remains live.

IMPORTANT. After completing the servicing or replacement of

components always:

• Test for gas soundness.

• Test the burner manifold flanges for soundness. This can be

done with leak detection spray whilst operating the boiler. The

gas valve and controls must be shielded from the spray.

• Check the water system is correctly filled and free of air.

Air in the boiler could cause damage to the heat exchanger.

For this reason if an automatic air vent is fitted it must

never be shut off.

• Check the inner front and outer jacket panels are correctly

fitted.

• With the system hot examine all water connections for

soundness.

• Check the gas rate and measure the combustion CO/CO

2

content. Refer to Frame 51 for reference on how to force

the burner to maximum and minimum gas rates. The CO/

CO

2

ratio of the flue gas on each module should not be

greater than 0.004 ratio. The CO

2

values should be correct

to the figures in Table 1 on Page 2.

• Carry out functional checks as appropriate.

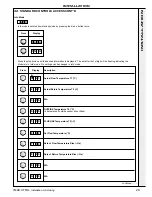

50 SERVICING SCHEDULE

To ensure the continued safe and efficient operation of the

appliance it is recommended that it is checked at regular

intervals and serviced as necessary. The frequency of servicing

will depend upon the installation condition and usage but should

be carried out at least annually.

Ideal Boilers

does not accept any liability resulting from

the use of unauthorised parts or the repair and servicing of

appliances not carried out in accordance with the Company's

recommendations and specifications.

Note

.

Some aluminium oxide build-up within the heat exchanger

assembly is quite usual with this type of condensing boiler.

Though removal and cleaning is recommended annually, the

heat exchanger, sump and condensate trap must be inspected

and cleaned after a maximum of 2 years operation.

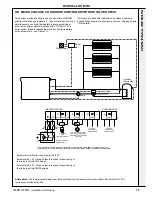

1.

Light the boiler and carry out function checks, noting any

operational faults.

2.

Run the boiler for 10 minutes and then check the gas

consumption rate. Refer to Frame 51 for reference on how

to force the burner to maximum and minimum rates.

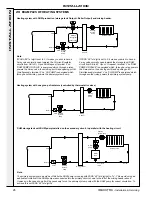

3.

For correct boiler operation the CO/CO

2

ratio of the flue gas

on each module should not be greater than 0.004 ratio and

the CO

2

values should be correct to the figures in Table at

front of book. If this is the case and the gas input is at least

90% of the nominal, once compliance with the note above is

ensured, then no further action need be taken. If not proceed

to 4. Refer to Frames 52 to 58 for guidance.

4.

Refer to Frame 49.

5.

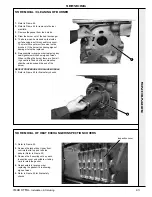

Remove and inspect the fan/venturi assembly. Refer to

Frame 53.

6.

Remove the burner manifold and inspect the electrodes and

sightglass. Refer to Frames 54 and 61.

7.

Remove and clean the burner. Refer to Frame 55.

8.

Inspect the heat exchanger through the burner opening.

Optionally remove the inspection covers on the left hand side

of the heat exchanger. If there are signs of aluminium oxide

build up, spray water down the flueways taking care not to get

water on the gas valve and controls. Refer to Frame 56.

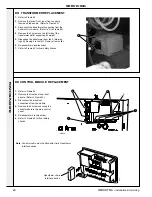

9.

Remove the sump cover and scrape out any deposits. Refer

to Frame 57.

10.

Clean the condensate trap. Refer to Frame 58.

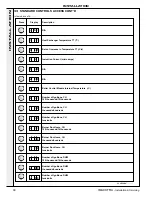

11.

Check that the flue terminal and air inlet are unobstructed and

that the fluing and ducting are correctly sealed.

REPEAT PROCEDURE FOR BOTH SLAVE AND MASTER

MODULES.

12.

After servicing refer to Frame 49 for final safety checks.

SER

VICING