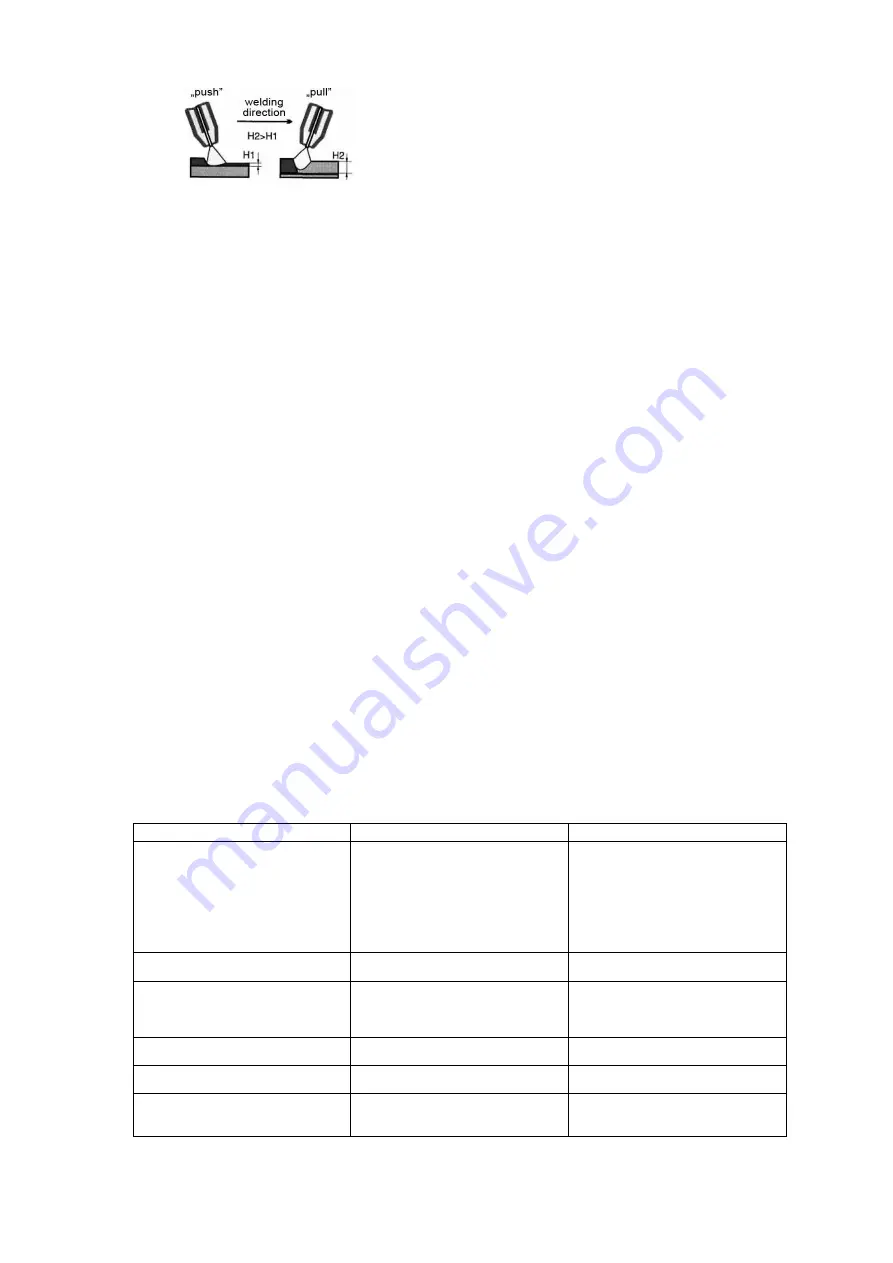

The penetration depth can differ according to welding

technique and torch position

H1, H2

– penetration depth

10. Welding using MMA process

The welding device can also be used for a stick electrode welding. To use that process turn the

MIG/TIG/MMA switch to MMA position. Connect the electrode holder plug into the positive socket

( + ) and the ground cable plug into the negative socket ( - ) leaving the polarization selector

unconnected. Using the welding current regulation knob (A) set the desirable welding current.

Please note that different electrode manufacturers may advise other polarization connections. In

such case please refer to electrode manufacturers information.

11. Cleaning and maintaining the device

The protection class of this device is IP21S. Do not use the device in the rain, nor expose it to

extensive moisture.

WARNING!

Device based on electronic components. Metal grinding and cutting close to the welder may

cause contamination of the inside of the device, thus causing its damage.

The damage mentioned above is not covered by the warranty. If you need to work in such

an environment, please clean device before use by blowing the inside of the welding

machine with compressed air.

To prolong the life and reliable operation of the device, several rules must be observed:

1. The device should be placed in a well-ventilated room where there is free air circulation.

2. Do not place the device on a wet surface.

3. Use a wire diameter and spool weight according to the table.

4. Check the technical condition of the device and welding cables.

5. Remove any flammable materials from the welding area.

6. Use suitable protective clothing for welding: gloves, apron, safety boots and welding helmet

12. Troubleshooting

Symptoms

Possible cause

Remedy

Wire feed does not feed the wire or

feeding is irregular (feeder motor is

working)

-

Feeding roll grooves are dirty

-

Contact tip is damaged

-

Locking mechanism is not

tighten

-

Torch liner is stuck with debris

-

Feeder roll type is wrong

-

Contact tip diameter is wrong

-

Clean or change roll

-

Change contact tip

-

Tighten the locking mechanism

-

Clean or change the liner

-

Mount appropriate roll

-

Check the contact tip and

change for a right one if needed

Wire feed does not feed the wire

(feeder motor is not working)

-

Faulty feeding motor

-

Control module failure

-

Turn directly to the service

centre

Arc is not igniting

-

Ground clamp not connected or

connected improperly

-

Polarization selector cable not

connected

-

Check the connection of the

ground clamp

-

Plug the selector to the

appropriate socket

Arc is too long and irregular

-

Welding current is to high

-

Wire feed is too slow

-

Adjust the current value

-

Change wire feed speed

Arc is too short

-

Welding current to low

-

Wire feed to fast

-

Adjust the current value

-

Change wire feed speed

ON/OFF button does not light up

-

No electric supply

-

Fuse failure

-

Switch malfunction

-

Check the power connections

-

Replace the fuse

-

Replace the switch