12

Response FF80

- Installation

Boiler

FF80

Max CH Output

kW

17.6

(Btu/h)

(60 000)

Water flow rate

l/sec

0.382

(gal/min)

(5.04)

Temperature

o

C

11

differential

(

o

F)

(20)

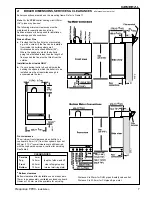

Head available for

m.w.g.

2.75

system pump, pos.3

(ft.w.g.)

9.0

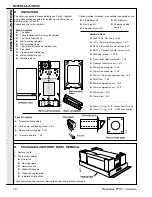

GENERAL

7. Thermostatic radiator valves.

Caradon Ideal Limited

support the recommendations

made by leading manufacturers of domestic heating

controls that heating systems utilising full thermostatic

radiator valve control of temperature in individual rooms

should also be fitted with a room thermostat controlling the

temperature in a space served by radiators not fitted with

such a valve. Such an arrangement will provide for a more

efficient control of the environment and will also avoid the

continuous running of the circulation pump during

programmed heating ON periods, saving electrical energy.

It is therefore strongly recommended that, when

thermostatic radiator valves are used, the space heating

temperature control over a living/dining area or a hallway,

having a heat requirement of at least 10% of the boiler

output, is achieved using a room thermostat whilst other

rooms are individually controlled by thermostatic radiator

valves.

However, if thermostatic radiator valves are fitted to

all

radiators then a bypass MUST be fitted. This should

consist of 22mm (

3/4

") pipe for the FF 80 positioned as far

from the boiler as possible and incorporating a balancing

valve

which cannot be adjusted by the householder.

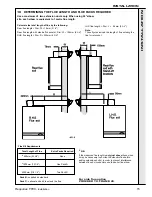

For adjustment refer to Frame 45

a.

The total length of pipework

A, B, C & D

MUST NOT

be less than 3m (10') and must not include any other

valves.

b.

The balancing valve MUST be at least one turn open.

8. Hydraulic resistance

Having subtracted the hydraulic resistance of the boiler the

head available to overcome system resistance at

MAXIMUM CENTRAL HEATING OUTPUT, with an 11

0

C

(20

0

F) temperature differential, is shown in Table 7.

9. Draining the system

Draining taps MUST be located in accessible positions to

permit the draining of the whole central heating system,

including the central heating side of the boiler. The taps

should be at least

1/2

" BSP nominal size and be in

5

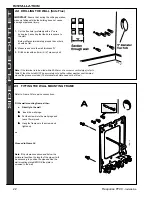

SEALED SYSTEM REQUIREMENTS - Central Heating - continued

1.

The domestic hot water service must be in accordance

with BS 5546 and BS 6700.

2.

For the minimum and maximum working pressures of the

FF80 domestic hot water circuit refer to Table 1, page 3.

3.

The cold water supply pipe should be flushed before fitting

the boiler.

4.

The boilers are suitable for connection to most types of

washing machine and dishwashing appliances.

6

DOMESTIC HOT WATER REQUIREMENTS

Table 7 - Water Flow Rate and Pressure Loss

5.

When connecting to suitable showers, i.e. those designed

for modulating domestic hot water, ensure that:

a.

The cold inlet to the boiler is fitted with an approved

anti-vacuum or syphon non-return valve.

b.

Hot and cold supplies are of equal pressure.

6. Hard water areas

In areas where the water is 'hard' it is recommended that a

proprietary scale-reducing device is fitted into the boiler

cold supply - within the requirements of the local water

company.

accordance with BS 2879. The boiler flow and return

service valves (fitted to the piping frame) have drain

plugs to drain the BOILER ONLY, in the event of the

system drain tap being unable to do so.