33

Response FF80

- Installation

45 GENERAL CHECKS

INSTALLATION

INST

ALLA

TION

1.

Hand the User's Instructions to the householder and

explain his or her responsibilities under the Gas Safety

(Installation and Use) Regulations 1994.

2.

Draw attention to the Lighting Instruction label affixed to

the inside of the lower front door.

3.

Explain and demonstrate the lighting and shutting down

procedures.

4.

The operation of the boiler and the use and adjustment of

ALL system controls should be fully explained to the

householder, to ensure the greatest possible fuel economy

consistent with household requirements of both heating

and hot water consumption.

5.

Advise the user of the precautions necessary to prevent

damage to the system and to the building, in the event of

the system remaining inoperative during frosty conditions.

6.

If a programmer kit is fitted, draw attention to the

Programmer Kit User's Instructions and hand them to the

householder.

7.

Stress the importance of regular servicing by a CORGI

registered installer and that a comprehensive service

should be carried out AT LEAST ONCE A YEAR.

8.

Emphasise to the user

that the boiler may stop

working if the system pressure is lowered by draining

radiators to decorate behind them. In particular,

explain to the user how the domestic hot water

temperature varies with flow rate. This is especially

important when water is drawn off while the boiler is

already running for central heating (refer to

'CAUTION' in User's Instructions, page 2).

After completing the installation and commissioning of

the system, the installer should hand over to the

householder by the following actions:

46 HANDING OVER

If an optional programmer kit is fitted refer to the instructions supplied with the kit.

Make the following checks for correct operation:

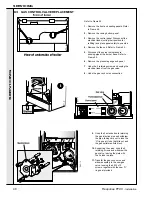

1. Hot water:

a.

Fully open all DHW taps in turn and ensure that water

flows freely from them.

b.

Close all taps except the furthest one from the boiler

and check that the boiler is firing at maximum rate.

c.

Use a screwdriver to turn the DHW flow adjuster

clockwise

to reduce the DHW flow rate until a DHW

temperature of approximately 35

o

C rise is obtained at

the tap. This corresponds to a flow rate of about 9.6 l/

min. (2.1 gpm).

d.

Turn off the DHW tap.

2. Central heating:

Operate each control separately and check that the main

burner or circulating pump, as the case may be, responds.

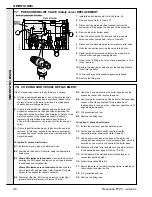

3. Gas rate:

Check the boiler gas rate when the boiler is at full output

(i.e. serving HW at a flow rate of at least 8 litres per minute,

open more than one tap if necessary).

The gas rate will normally be between 43.1 and 47.7 litres

per minute (1.52 to 1.68 cu/ft min.), checked at the gas

meter, with no other appliance in use. If this check is not

possible, ensure that the burner pressure lies in the range

13.3 to 16.4 mbar). These figures apply at the nominal UK

mains voltage of 230V: if the voltage is significantly higher,

the fan will speed up slightly and cause the gas valve to

pass slightly more gas. Conversely, very long flues reduce

the air flow, and gas rate, slightly.

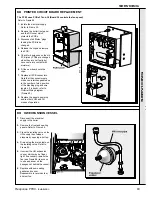

4. Water circulation system:

Note.

Fernox Superfloc flushing solution should be used

during the flushing procedure.

a.

With the system HOT examine all water connections

for soundness.

b.

With the system still HOT, turn off the gas, water and

electricity supplies to the boiler and drain down, to

complete the flushing process.

c.

Refill the system, adding inhibitor (see 'Water

Treatment'), if required.

Vent as necessary to clear all air and, again, check for

water soundness. After venting, repressurise as

required.

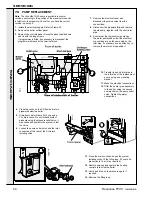

d.

Balance the system.

It is suggested that, initially, all radiator handwheel

valves (or TRVs if fitted) be set fully open, that all

lockshield valves be set a half-turn open and the

bypass a half-turn to one turn open (a minimum of one

turn open is recommended when TRVs are used.)

Make minor adjustments to each radiator to achieve

the same differential on all.

Lastly, set the bypass to eliminate any boiler noise,

without compromising radiator temperatures.

5.

Finally, set the system controls to the user’s requirements.