41

Response FF80

- Installation

SER

VICING

SERVICING

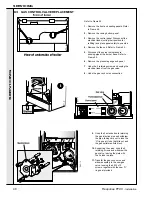

64 GAS CONTROL VALVE REPLACEMENT - continued

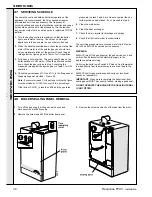

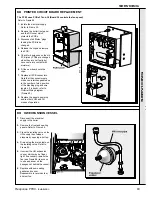

65 WATER PRESSURE GAUGE

5.

Disconnect the capillary at the

CH flow pipe boss.

6.

Squeeze the tabs to release the

pressure gauge.

7.

Fit the replacement gauge and

reassemble in reverse order.

8.

Close all drain cocks and open

both isolating valves.

9.

Fit the filling loop. Fill the boiler

with water and pressure to 1 bar

(as appropriate). Reconnect

services.

10.

After satisfactory test firing and

removal of air from the system,

remove the filling loop.

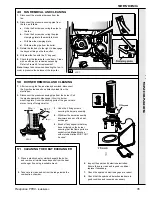

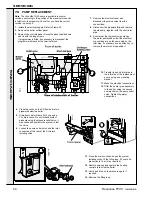

1.

Disconnect the electrical supply to the boiler.

2.

Remove the bottom panel.

3.

Remove the controls panel. Swing the panel upside down

and fix with the long screws.

4.

Close the isolating valves on CH flow/return at base of

boiler then, release CH system pressure by opening one of

the CH drain cocks on the isolating valves.

It is not advisable to release system pressure using the

safety valve.

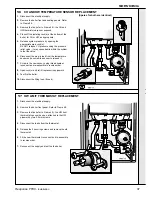

12.

Offer the gas valve to the plate, making sure that the

stud feeds in to the corresponding hole the rear of the

metal plate.

Fix the gas valve and plate in place, using the 4 M5 x

10 pozi pan screws.

Refit the manifold block and injector pipe, checking that

gasket and 'O' ring are undamaged.

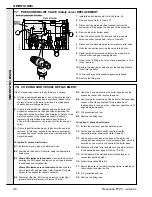

13.

Check the operation of the new gas valve.

14.

Operate the boiler for at 10 minutes at full rate and

check the burner pressure against the value shown on

the date plate for CH or HW as appropriate.

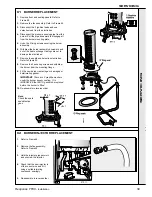

15.

Fit the new gas valve in reverse order, ensuring that the

gas injection pipe 'O' ring seal is refitted.

16.

Check the operation of the new gas valve.

17.

Operate the boiler on HW for at least 10 minutes at full

rate and check the burner pressure against the value

shown on the data plate or in Table 3.