44

Response FF80

- Installation

SERVICING

SER

VICING

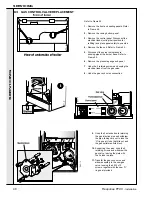

70 PUMP REPLACEMENT

Note.

The Grundfos 15/60 pump is available in several

versions, according to the position of the electrical connector

in relation to the pipework. Check that you have the correct

version - see step 9.

1.

Isolate the electrical supply. Refer to Frame 55.

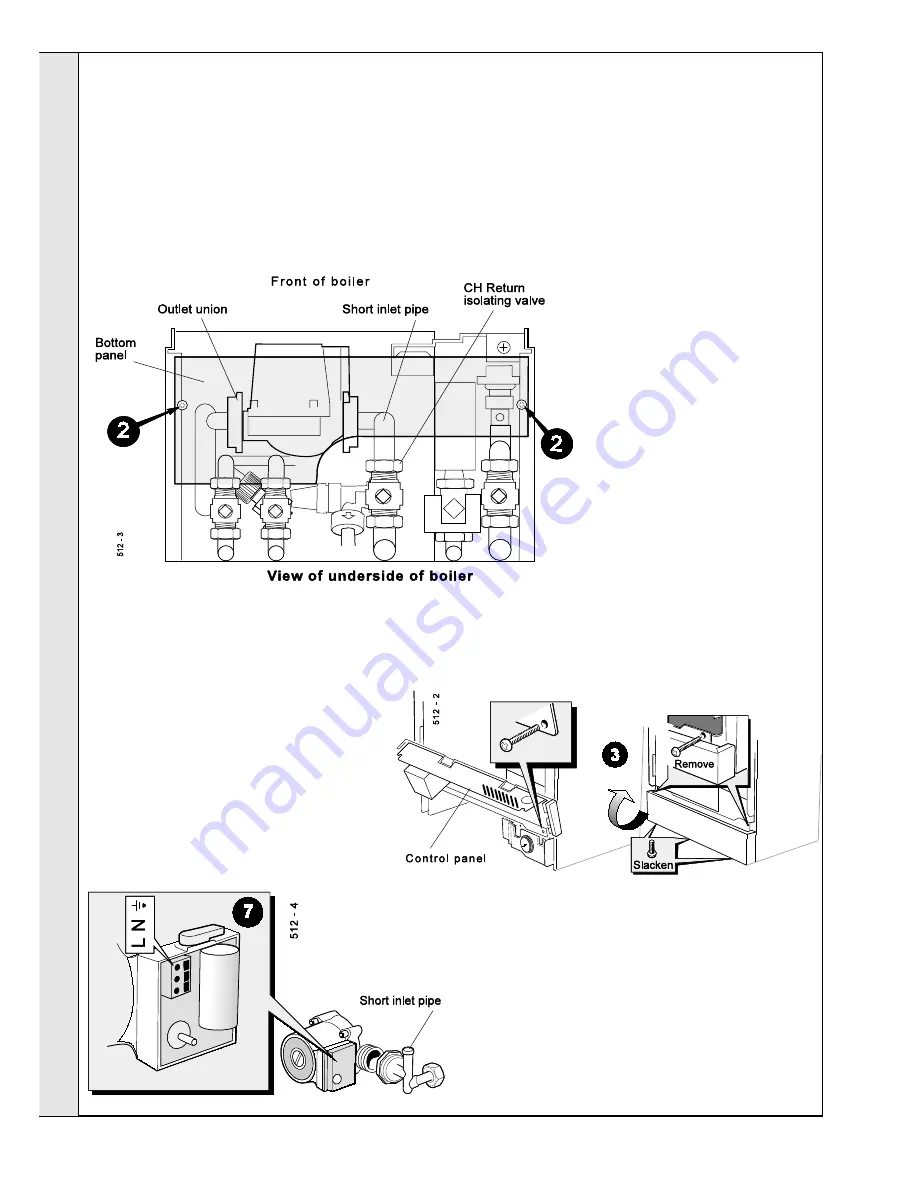

2.

Remove the boiler bottom panel.

3.

Remove the controls panel. Swing the panel upside down

and fix with the long screws.

If programmer is fitted, its necessary to disconnect the

programmer harness at the terminal block.

4.

Close the cocks on the CH flow and return

pipework below the boiler.

5.

Drain down (refer Frame 52) by opening

CH. drain cocks. Do not release system

pressure using the pressure relief valve, it

may cause debris within the system to foul

the valve.

6.

Loosen the pump outlet union and the inlet

connection at the rear of the CH return

isolating valve.

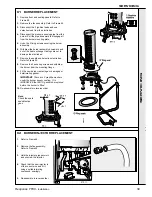

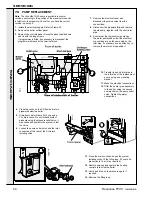

13.

Close the drain cocks and open the system

isolating cocks, fit the filling loop, fill, vent and

pressurise to 1bar (or as required).

14.

Restore services and operate the heating

controls to test-fire the boiler.

15.

Vent air and top up the pressure again, if

required.

16.

Remove the filling loop.

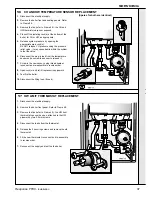

10.

Transfer the short inlet pipe to

the

inlet

side of the replacement

pump, using a new sealing

washer.

11.

Make the electrical connections.

12.

Offer the pump / pipe assembly

to the boiler, using the second

new washer on the pump outlet

union. Tighten the water

connections.

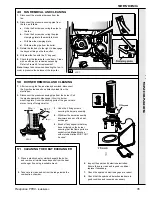

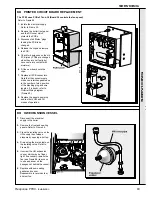

7.

Remove the electrical cover and

disconnect the mains wires from the

connections.

8.

Disconnect the pipework fully and remove

the old pump, together with the short inlet

pipe.

9.

Ensure that the replacement pump has

the motor positioned

so that the electrical

connections are on the same side as the

inlet pipe.

If necessary, use an Allen key to

remove the motor and reposition it.