45

Response FF80

- Installation

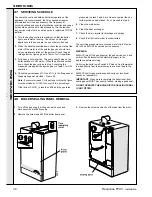

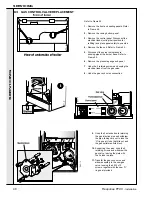

71 HEAT EXCHANGER REPLACEMENT

SERVICING

SER

VICING

withdraw the assembly downwards, taking care not to

damage the electrodes - refer to Frame 61.

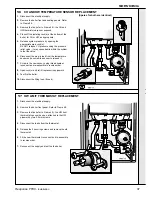

12

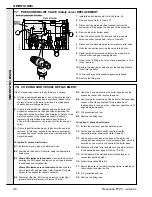

. Unplug the electrical leads from both CH and HW

temperature sensors and disconnect the leads from the HW

overheat thermostat. Unscrew the CH temperature sensor

and remove it, to avoid damage to it - refer to Frames 56

and 57.

13.

Loosen the top and bottom connections on the 22mm CH

pipes to the heat exchanger.

14

. Loosen the bulkhead connectors at the lower end of the

15mm HW pipes, together with the hexagon socket screws

retaining the upper ends of these pipes. The inlet pipe can

now be swung round and withdrawn, complete with HW

expansion vessel.

The straight outlet pipe cannot be removed until later - see

paragraph below.

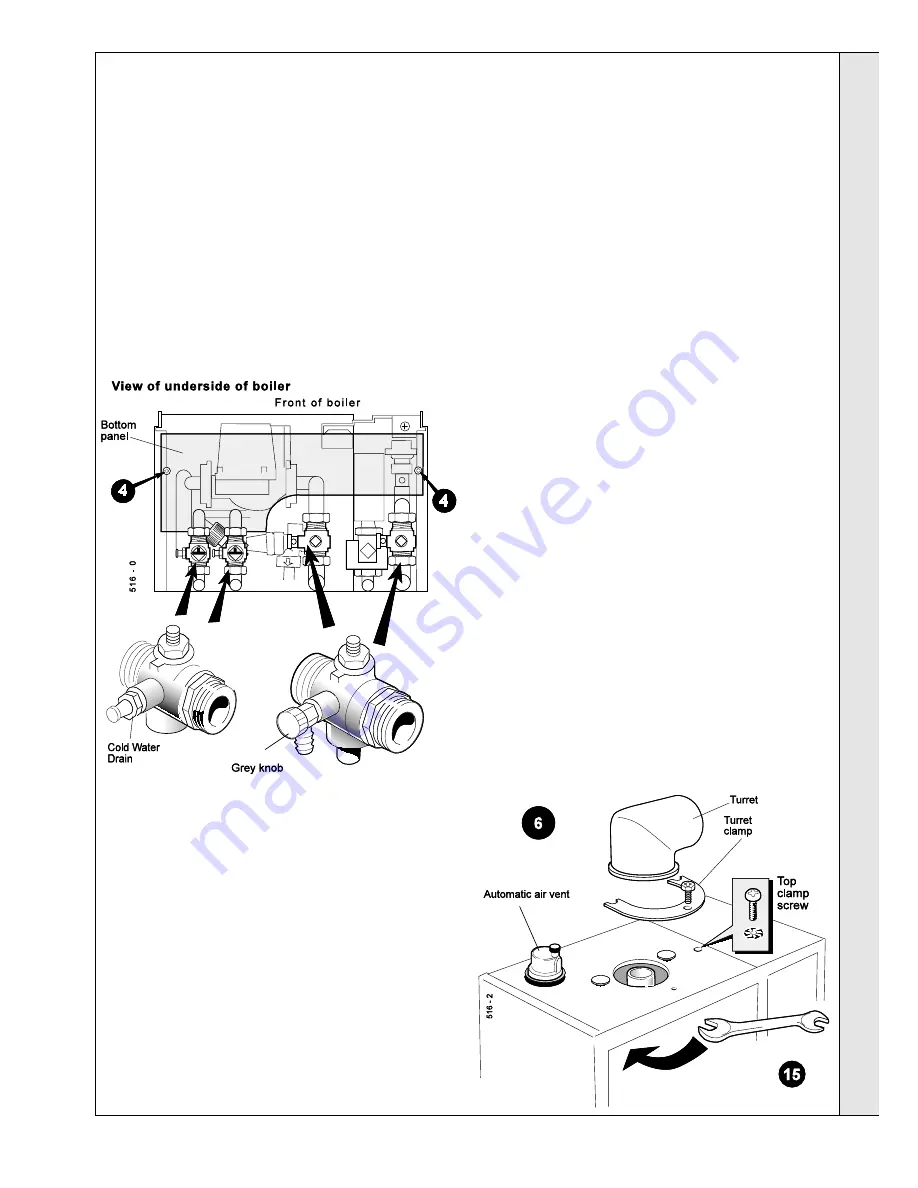

15

. Unscrew the automatic air vent on the top of the heat

exchanger. This should be done inside the jacket in order

not to unscrew merely the top off the air vent.

16.

Next remove the 2 screws securing the heat exchanger

from below, together with the top clamp screw.

17.

The heat exchanger is now free and should be supported

whilst removing the HW outlet pipe.

18.

Remove heat exchanger from the boiler.

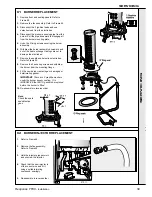

19.

Re-assemble in reverse order, using new gaskets as

appropriate.

20.

Before refitting the fan, check that the wires have been

reconnected to the CH sensor (mauve pair), HW sensor

(grey), overheat 'stat (black) and flame detection electrode

(yellow).

21.

When re-assembly is complete, fit the filling loop, close all

drain points, open all isolating valves and ensure that the

boiler is filled, vented of air and pressurised before

attempting to fire it.

22

. After a satisfactory test firing, remove the filling loop (this is

a requirement of the water bylaws).

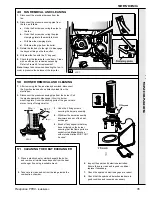

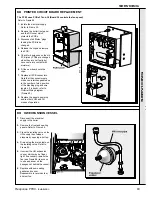

6.

While the boiler is draining, release the turret clamp on top

of the boiler, together with the screw securing the turret to

the flue pipe. Remove the turret.

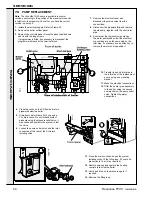

7.

Disconnect the fan pressure sensing pipe by removing the 2

screws at the fan end and the screws of the securing plate

at the gas valve end. Remove the pipe- refer to Frame 66.

8.

Unplug the wiring harness from the fan. Release the clip

securing the fan and rotate the fan towards you until it is

free of its bayonet mounting socket (the fan may

alternatively be removed complete with harness) - refer to

Frame 66.

9.

The second pressure sensing pipe, which is connected via

an 'O' ring seal to the burner base may now be carefully

withdrawn downwards.

10.

Disconnect the spark electrode leads and the flame sensing

electrode lead at the burner base - refer to Frame 59.

11.

Remove the 3 screws securing the burner assembly and

WARNING.

This will necessitate disconnection of all services,

including the flue turret.

Refer also to Frame 7 - 'Boiler Exploded View'.

1.

Isolate the electrical supply to the boiler.

2.

Isolate the water and gas supplies by closing all 4 cocks

below the boiler.

3.

Remove the boiler front panel and inner sealing panel -

refer to Frame 48.

4.

Remove the bottom panel.

5.

Attach drain pipes to the 4 boiler drain points, one on each

isolating valve. Open the CH drains by turning the grey

knobs and the HW drains by slackening the drain nipple.

Note the marking on the bottom of the valves. Refer to

Frame 52