B-2048-1(1)

INSTRUCTION SHEET - HS1T Series

Solenoid Type Safety Switch

( 3 / 9 )

2019.07

4

Precautions for Operation

(Actuator deviation) + (Door movement)

≤ 3.8mm

≤ 3.8mm

HS9Z-A11T

HS9Z-A12T

For Mounting

• Do not apply an excessive shock to the safety switch when opening or closing the

door. A shock to the safety switch exceeding 1,000 m/s

2

may cause failure.

• Provide a door guide, and ensure that force is applied on the safety switch only in

the actuator insertion direction.

• Do not pull the actuator while it is locked. Also, regardless of door types, do not use

the safety switch as a door lock. Install a separate lock as shown in section 3.

• Ensure that the safety switch is installed on a flat

mounting surface, and provide

sufficient strength

to the mounting surface so that it will not be distorted during

operation. Make sure that no foreign objects are caught between the safety switch

and mounting surface. Uneven surface, distorted surface, or foreign objects may

result in the malfunction of safety switch.

• Entry of foreign objects in the actuator entry slot may affect the mechanism of the

switch and cause a breakdown. If the operating atmosphere is contaminated, use a

protective cover to prevent the entry of foreign objects into the switch

through the actuator entry slots.

• Make sure to install the product in a place where it cannot be damaged.

Make sure to conduct a proper risk assessment evalua ion before using

the product, and use a shield or a cover to protect the product if need be.

• While the solenoid is energized, the switch temperature rises approximately 40°C

above the ambient temperature (to approximately 95°C while the ambient tempera-

ture is 55°C). Keep hands off to prevent burns. If cables come into contact with the

switch, use heat-resistant cables.

• Solenoid has polarity. Be sure to wire correc ly. Do not apply voltage that exceed the

rated voltage, otherwise the solenoid will be burnt out.

• Do not fasten and loosen the conduit at he bottom of the safety switch.

• Use the dedicated actuators only. Other actuators will cause damage to the switch.

• Be careful not to injure yourself with the screwdriver tip when wiring the terminals.

• Be careful not to damage the square-shaped screwdriver port when inserting the

driver into it in order to wire the terminals. Inserting the screwdriver with too much

strength may damage the product.

• Before using the following accessories, be sure to refer to the instruc ion manual for

the respective accessory and follow the instructions in the manual to ensure correct

use. HS9Z-FL5

CAUTION

• HS1T Series Safety Switches are Type 2 low-level coded interlocking devices (EN

ISO / ISO14119). The following system installation & mounting instructions are EN

ISO / ISO14119 requirements to prevent function failure from the interlock switch.

1. Using permanent fixing methods (e.g. welding, rivets, special screws...etc) to

prevent dismantling or de-positioning of the interlock device. However, perma-

nent fixing methods are not an adequate solution if you expect the interlock

device to fail during the machinery lifetime, or if you need to replace the prod-

uct in quick manner. In these situations, other measures (see 2.) should be put

in place to reduce the risks of function failure.

2. At least one of the following measures should be applied to prevent function

failure.

(1) Mounting the interlock device in a place out of reach from workers

(2) Using shielding protection to prevent physical obstruction of the device

(3) Mounting the interlock device in a hidden position

(4) Integrate status monitoring & cycling testing of the device to the control

system to prevent product failure.

• Regardless of door types, do not use the safety switch as a door stop. Install a

mechanical door stop to the end of the door to protect the safety switch against

excessive force.

• Mount the actuator so that it will not hit the operator when the door is open, other-

wise injury may be caused.

• Pay attention to the management of spare actuator. Safety function of door inter-

lock switch will be lost in case the spare actuator is inserted into the interlock

switch. Ensure that the actuator is firmly fastened to the door (welding, rivet, special

screw) in the appropriate location, so that the actuator cannot be removed easily.

• Do not cut or remodel the actuator, otherwise failure will occur.

• If multiple safety components are wired in series, the Performance Level to

ISO13849-1 will be reduced due to the restricted error detection under certain

circumstance.

• The insulation of the cable has to withstand environmental influences.

• The entire concept of the control system, in which the safety component is

integrated, must be validated to ISO13849-2.

• When there is a displacement of safety switch and actuateor, the actuator may hit the

entry slot of safety switch hardly, thus damaging the entry slot and acutuator. The

rubber cushions on the HS9Z actuator prevent the actuator from damaging the entry

slot by absorbing the shock with movement flexibility. Do not, however, exert

excessive shocks, otherwise the failure of safety switch may be caused.

• The rubber cushions may deteriorate depending on the operating enviroment and

conditions. Immediately replace the deformed or cracked rubber cushions with new

ones.

For Type HS9Z-A11T/A12T actuator

Name or Use

For mounting the safety switch (M5 screw) *7

For mounting the cover(M3screw)

For Rotation Stopper Screw of the Head (M4screw)

For mounting the rear unlock button

(M3 sems screw)

For mounting the actuator

(HS9Z-A11T/A12T : two M5 screws) *8

Screw Tightening Torque

3.2 to 3 8 N•m

0.5 to 0.7 N•m

0.1 to 0.3 N•m

0.5 to 0.7 N•m

2.7 to 3.3 N•m

Recommended Screw Tightening Torque

Safety

Switch

Center

Center

*7 When the torque is not enough to recommended screw tightening torque, make

sure that the screw do not become loose by using adhesive sealants etc. to

keep right operation and mounting posi ioning.

CAUTION

WARNING

• Turn off the power to the safety switch before starting installation, removal, wiring,

maintenance, and inspection on the safety switch. Failure to turn power off may

cause electrical shocks or fire hazard.

• Do not disassemble or modify the switch. Also do not attempt to disable the

interlock switch function, otherwise a breakdown or an accident will result.

Actuator Mounting Tolerance

• Mounting tolerance of the actuator is 0.5 mm in the four lateral directions.

• Make sure the actuator can be inserted into he entry slot without any issue.

Actuator Mou ting Tolerance

M unting t leran e f the a tuat r is 1 0 mm in the four lateral dire ti ns

• Make sure he actuator can be inserted into he entry slot without any issue

• When closing the door, the actuator is inserted and locked within a certain distance

from the reference position. After the actuator has been locked, the contact operation

is not affected by the actuator movement in the locked state.

HS9Z-A12T

HS9Z-A11T

3.8mm

3.8mm

±0.5mm

±0.5mm

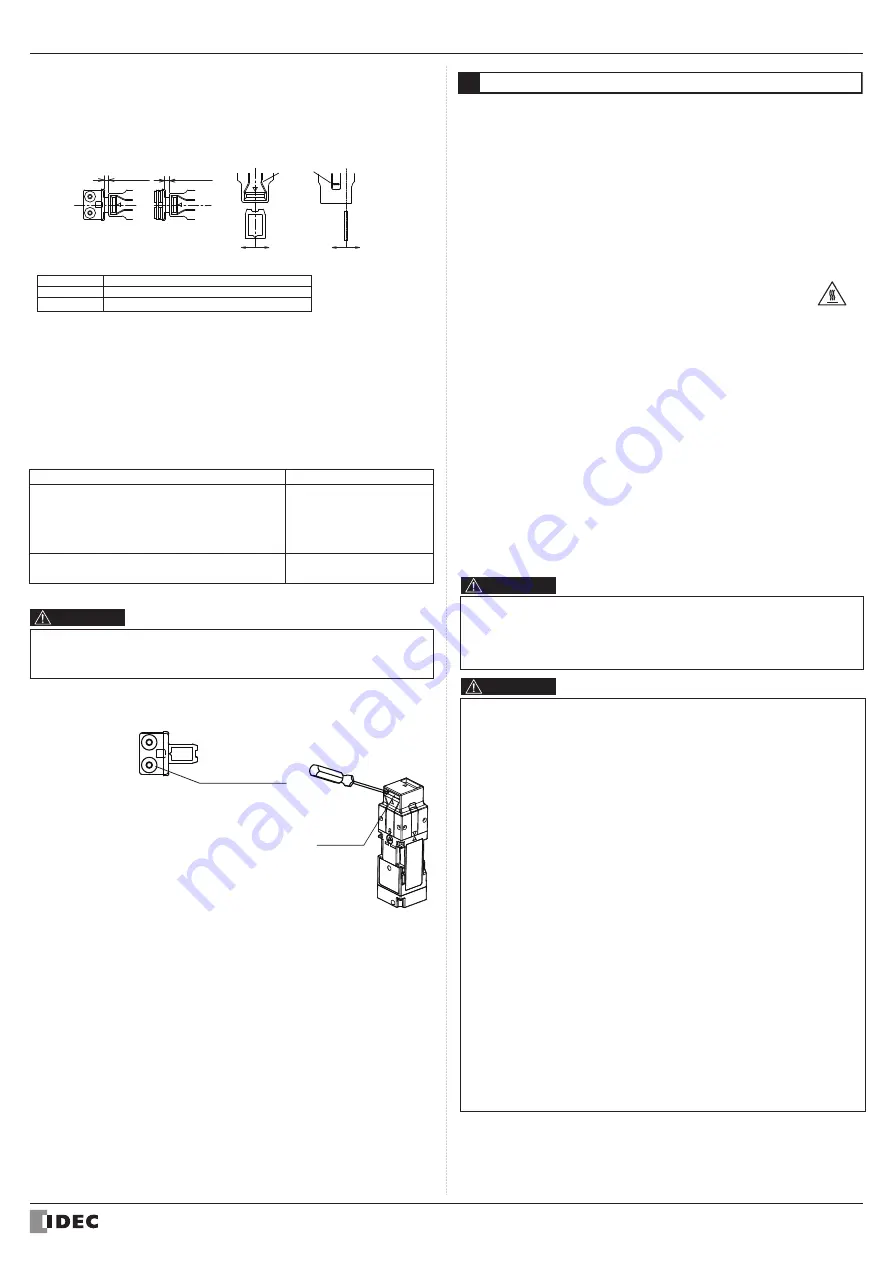

Slot plug

・

When not in use, close up the safety switch

actuator entry slots with slot plugs to prevent

dust from entering.

・

Actuator entry slots on the front come closed up

wi h slot plugs at time of shipment. When replacing,

please use the tool as shown.

●

Installing the slot plug

Rubber Cushions

*8: When rubber cushions (and spacers) are not used, use M6 screws and tighten to a

torque of 4.5 to 5.5 N

・

m.