B-2048-1(1)

INSTRUCTION SHEET - HS1T Series

Solenoid Type Safety Switch

( 4 / 9 )

2019.07

5

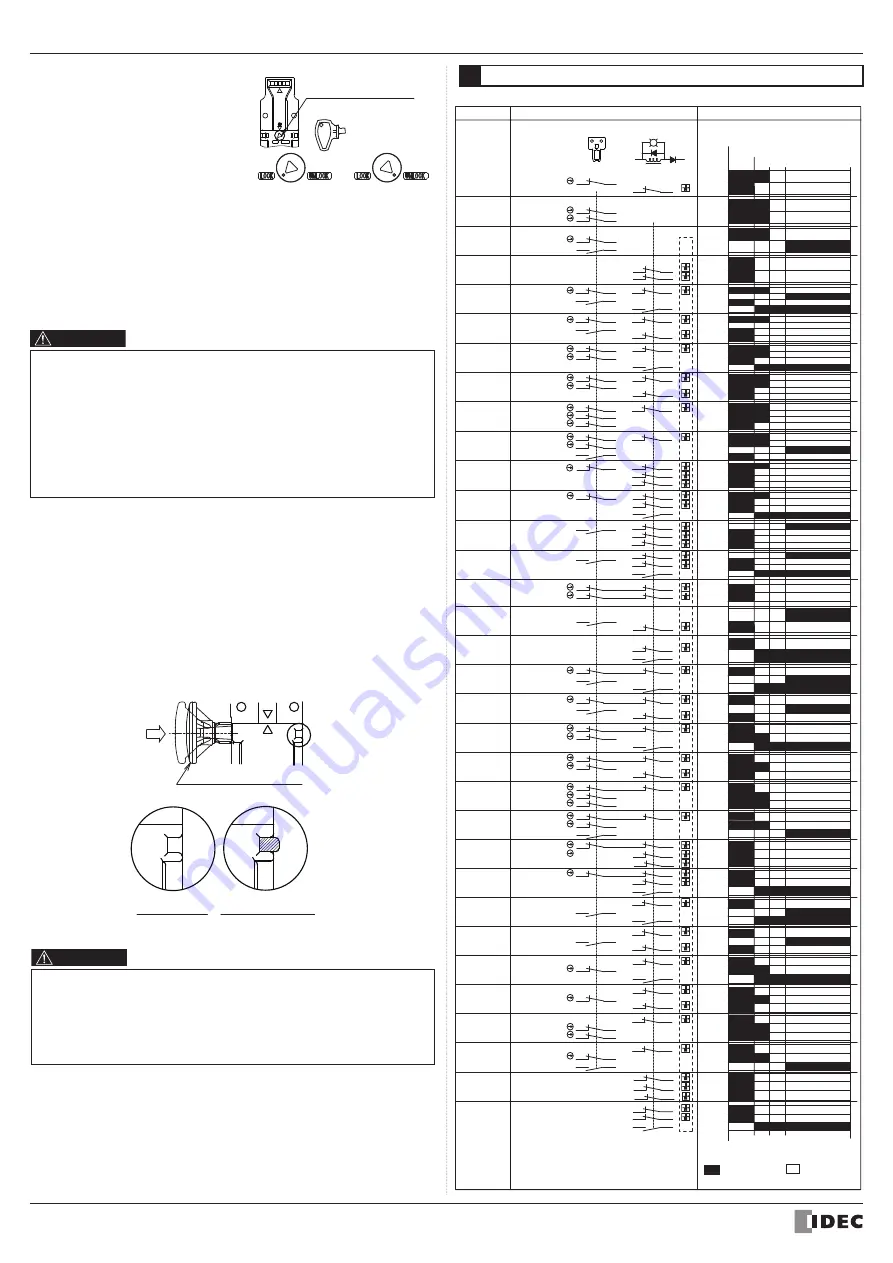

Contact Operation

(Actuator

Completely Inserted)

(Actuator

Pulled Out)

:

Contact Closed

:

Contact Open

Approx. 4 2 (Lock)

0 (Actuator Mounting Reference Position)

Approx.

28.5

Approx

.9.8

Approx.

11.6

(Travel: mm)

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

(Type HS1T-

□

4)

The HS1T allows manual unlocking of the actuator to precheck proper door opera-

tion before wiring or turning power on, as well as for emergency use such as a power

failure.

(Type HS1T-

□

7Y)

If the actuator is not unlocked althoug the solenoid is deenergized, the actuator can

be unlocked manually.

CAUTION

• Before manually unlocking the safety switch, make sure the machine has come to a

complete stop. Manual unlocking during operation may unlock the switch before the

machine stops, and the function of safety switch with solenoid is lost.

• While the solenoid is energized, do not unlock the actuator manually (solenoid lock

type).

• Do not apply excessive force (0.45 N•m or more) to he manual unlock key. Otherwise

the manual unlock switch will be damaged. Do not attach the key to the switch

intentionally (the key is designed to fall off when the operator's hand is off the key).

• Do not leave the manual unlock key attached to the switch during operation. This is

dangerous because the switch can always be unlocked while the machine is in

opera ion.

CAUTION

• Install the HS1T to ensure that a worker can operate the rear unlock button from

inside the safety hedge (the dangerous area). It is dangerous to install the HS5L in

the position where the rear unlock button can be operated from outside the the

safety hedge (the dangerous area), because it is possible to unlock while the

machine is opera ing.

• Use hand to press the button, and do not use a tool. Do not apply excessive force

to the rear unlock button.

• To change the normal position to the

manual unlocking position as shown

above, turn the key fully (90 degrees)

using the special key included with the

switch.

• Using the switch with the key being not

fully turned(less than 90 degrees) may

cause damage to the switch or errors.

• When manually unlocked, the switch will

keep the main and lock monitor circuit

disconnected and the door unlocked.

For Manual Unlocking

Normal

Position

Manual

Unlocking

Position

Manual Unlock Key

attached to the

safety switch

Manual Unlock Key Hole

For the Rear Unlock Button and Indicator

(Type HS1T-

□

L)

• The rear unlock button is used for an emergency escape when he worker is confined in he

safety hedge (the dangerous area).

(The rear unlock button is according to EN ISO / ISO14119, GS-ET-19)

• The lock is released when the rear unlock button is pressed, and the door can be opened.

• To return to the locked status, pull back the button. While the rear unlock button is

depressed, the main circuit remains open and the door is unlocked.

• Each time the rear unlock button is pressed, the indicator is displayed on the side of he

safety switch.

Enables checking of the unlock status from outside he safety hedge.

• Use the rear unlock indicator by attaching it to the display area on either side of the safety

switch.

The Rear Unlock Button

Lock

Release

Rear Unlock Status

Normal Status

●

Contact Configuration and Operation

Contact Congifiguration *11

※

9

[

HS1T-TJ

□

]

[

HS1T-TG

□

]

[

HS1T-TF

□

]

[

HS1T-TD

□

]

[

HS1T-TC

□

]

[

HS1T-TB

□

]

[

HS1T-TA

□

]

[

HS1T-J

□

]

[

HS1T-G

□

]

[

HS1T-F

□

]

[

HS1T-D

□

]

[

HS1T-C

□

]

[

HS1T-B

□

]

[

HS1T-A

□

]

[

HS1T-XB

□

]

HS1T-DD

□

HS1T-VG

□

HS1T-VH

□

HS1T-VF

□

HS1T-VD

□

HS1T-VC

□

[

HS1T-VB

□

]

HS1T-VA

□

HS1T-XH

□

[

HS1T-XG

□

]

[

HS1T-XF

□

]

HS1T-XD

□

11

23

24

53

54

42

11-42

23-24

53-54

23

11

24

51

52

42

11-42

23-24

51-52

11

21

22

53

42

54

11-42

21-22

53-54

11

21

22

51

42

52

11-42

21-22

51-52

11

21

33

22

34

42

11-42

21-22

33-34

11

21

31

22

32

42

11-42

21-22

31-32

11

63

51

64

52

42

11-42

51-52

63-64

21

11

42

52

11-42

21-52

23

11

12

24

41

53

42

54

11-12

23-24

41-42

53-54

11

23

24

12

41

51

42

52

11-12

23-24

41-42

51-52

21

11

12

22

53

41

54

42

11-12

21-22

41-42

53-54

21

11

22

12

51

41

52

42

11-12

21-22

41-42

51-52

31

21

11

32

22

12

41

42

11-12

21-22

31-32

41-42

33

21

11

34

22

12

41

42

11-12

21-22

33-34

41-42

11

21

12

22

11-12

21-22

11

23

12

24

11-12

23-24

51

41

52

42

41-42

51-52

11

12

41

42

11-12

41-42

13

14

41

42

13-14

41-42

13

14

53

54

41-42

13-14

53-54

41

42

11

12

51

52

41-42

11-12

51-52

41

42

21

11

22

12

41-42

11-12

21-22

41

42

63

51

64

52

41-42

51-52

63-64

41

42

23

11

24

12

41-42

11-12

23-24

41

42

14

51

52

41-42

13-14

51-52

41

42

13

11

12

53

54

41-42

11-12

53-54

41

42

HS1T-VJ

□

HS1T-VW

□

HS1T-VX

□

11

12

63

51

41

64

52

42

11-12

41-42

51-52

63-64

[

HS1T-XJ

□

]

53

41

54

42

41-42

53-54

A1

A2

(

+

)

(

-

)

11

12

61

51

41

62

52

42

61

51

41

62

52

42

13

14

13

14

63

51

41

64

52

42

13-14

41-42

51-52

63-64

13-14

41-42

51-52

61-62

11-12

41-42

51-52

61-62

[

HS1T-H

□

]

[

HS1T-TH

□

]

11

42

51

52

61

62

11-42

51-52

61-62

41

42

51

52

61

62

41-42

51-52

61-62

Type *10

Contact Operation (reference)

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Monitor Circuit:

Main Circuit:

Main Circuit: