( 6 / 9 )

B-2048-1(1)

INSTRUCTION SHEET - HS1T Series

Solenoid Type Safety Switch

2019.07

Note : Confirm the outside diameter of the multi-core cable, the connector type

depends on the outside diameter of multi-core cable.

Note : When using ST-M20×1.5, use with gasket GP-M (Type No: GPM20, made by

LAPP).

Note : If you use HS1T as Type 4X

Indoor Use Only

, please use M20 connectors that are

certified the following.

Plastic connector: Type 4,4X, 6 or 6P

Metal connector: Type 4X or 6P

Note : To unwire the terminals, disassemble the product in the following order:

turn off the power → loosen connecter B → remove the terminal cover →

remove the waterproof gasket from connecter A* → loosen connecter A

* Please remove the water-proof gasket carefully with tools such as tweezers.

Be careful when removing the gasket as damages may affect its waterproof

properties. Also, loosening connecter A without removing the gasket first may

damage the cable and provoke connection issues. Please make sure you

re-insert the waterproof gasket properly into connector A when re-assembling

the product.

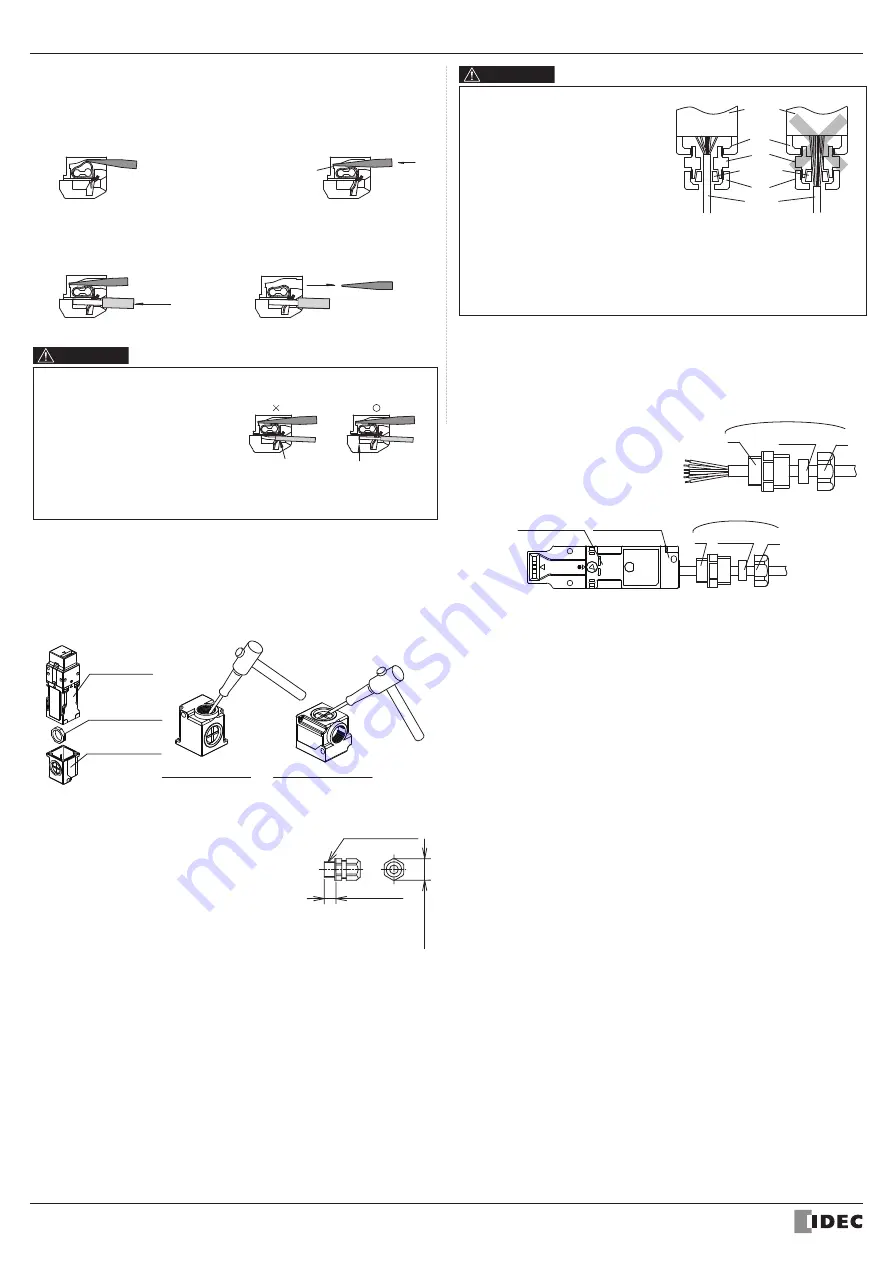

• Wiring Instructions

1. Insert the applicable screwdriver into

the square-shaped port as shown,until

the screwdriver tip touches the bottom

of the spring.

3. While the screwdriver is retained in

the port, insert the wire or ferrule into

the round-shaped wire port. Each wire

port can accommodate one wire or

ferrule.

Bottom of the Port

Safety Switch Terminal Cover

Gasket

Connecter

(To buy separately)

How to open conduit port (cable side-routed type)

• Before use, knock in the conduit port where the connector is to be connected, using

a tool such as screwdriver as shown in the figures.

• Before opening the conduit port, remove the terminal cover from the HS1T Safety

Switch main unit, and remove the locking ring for the cable gland installed in the

terminal cover.

• Be sure to remove any crack or burrs on the conduit port, as it will impair waterproof

performance.

Safety switch

Straight orientation

Horizontal orientation

Locking ring

for cable gland

Terminal cover

A

B

4. Pull out the screwdriver.

The connection is now complete.

2. Push in the screwdriver until it touches

the bottom of the port. The wire port is

now open, and the screwdriver is held

in place. The screwdriver will not come

off even if you release your hand.

The waterproof

gasket is completely

tightening the cable

The waterproof

gasket is not

properly tightening

the cable

Spring Force

Terminal

Spring Force

Terminal

Safety

Switch

A

Gasket

Sheath

B

Terminal

Cover

CAUTION

• Make sure not to lose any screw when

removing the terminal cover from the

switch.

• Please make sure the cable is insterted

deep enough into the terminal cover so

that the waterproof gasket can tighten

he cable sheath completely and ensure

its waterproof functions.

• Make sure you always tighten connecter

A before connecter B, otherwise the

wires which connect the terminals might

get twisted or might break, and this

might also damage the terminal ports.

• When tightening the connecters, only

use a tightening torque that is approved by the connecters' manufacturer to

ensure waterproof properties of the product.

• Do not pull or twist the cable with excessive force, otherwise you might damage the

wires inside of it.

Use a connector with a degree of protection IP67.

Applicable connector dimensions : See the figure on the right.

• When using flexible conduit and metal connector

Applicable Flexible Conduit Example:

Type VF-03 (made by Nihon Flex)

(M20) Applicable Metal Connector Example:

Type RLC-103EC20 (made by Nihon Flex)

• When using plastic connector, metal connector and multi-core cable

(M20) Applicable Plastic Connector Example:

Type ST-M20×1.5 (made by LAPP)

Applicable Metal Connector Example:

Type ALS-

□□

EC20 (made by Nihon Flex)

9mm max.

Conduit Thread

30mm max.

Applicable Connectors

A

B

Connecter (To buy separately)

Gasket

1. Loosen connecter A and connecter B, and insert the cable into these pieces in the

following order :

connecter B → waterproof gasket → connecter A.

Do not tighten the connecters yet.

2. Remove the terminal cover from the switch

and insert the cable into the cover.

3. Wire the terminals.

4. Tighten connecter A into the terminal cover.

Fix the terminal cover back into its original

position. Tighten connector B.

Connecters' mounting method

Correct

The wire is inserted

deep enough

between the clamps

Incorrect

The wire insula ion

sheath is in contact

with the clamps

CAUTION

• When using wire with insulation

diameter of Φ2.0mm or less, do not

insert the wire too deep where the

insulation inserts into the spring clamp

opening. Otherwise conductive failure

will be caused. Make sure that the

wire insulation is stripped 8 to 9 mm

and the wire is inserted to the bottom.

• Please only connect one wire per

terminal port (according to the general

requirements section (13.1.1) of

IEC60204).