57

HS5E-K Interlock Switches with Key

Ratings

Contact Rating

Rated Insulation Voltage (Ui) (Note 1)

250V

Rated Thermal Current (Ith)

Operating temperature:

–25°C to 60°C: 2 .5A max .

60°C to 65°C: 1 .5A max .

65°C to 70°C: 1 .0A max .

Rated Voltage (Ue)

30V

125V

250V

Rated

Current

(Ie)

(Note 2)

AC

Resistive Load (AC-12)

−

2A

1A

Inductive Load (AC-15)

−

1A

0 .5A

DC

Resistive Load (DC-12)

2A

0 .4A

0 .2A

Inductive Load (DC-15)

1A

0 .22A

0 .1A

Minimum applicable load (reference value) = 3V AC/DC, 5 mA

(Applicable range may vary with operating conditions and load types .)

Note 1: UL rating:

125V

Note 2: TÜV rating:

AC-15, 0 .5A/250V, DC-13, 0 .22A/125V

UL, c-UL rating: Pilot Duty AC 0 .5A/125V,

Pilot Duty DC 0 .22A/125V

Key Specifications

Operating Method

2-position maintained

Mechanical Durability

100,000 operations minimum

Insertion/Removal Durability

10,000 operations minimum

Operator Strength

1 .0 N·m minimum

Direct Opening Force

0 .6 N·m minimum

Direct Opening Angle

60° minimum

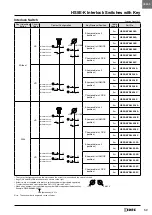

Part No. Development

H S 5 E - K V A 0 L 0 3 - 2 A 5 0 1

VA:

VD:

Circuit Code

Pilot Light

0: None

Main

Circuit

Door Monitor

Circuit

Lock Monitor

Circuit

1NC, 1NO

2NC

—

—

1NC, 1NO

2NC

Rear Unlocking Button

L: With

Blank: Without

Cable Length

03: 3m

05: 5m

Key removal specifications

A: Removable in

all positions

B: Removable at UNLOCK

C: Removable at LOCK

Key number

Blank: Standard Key

number (500)

or

501 to 515

Operator position

2: 2-position

General Specifications

Applicable Standards

ISO14119, IEC60947-5-1,

EN60947-5-1 (TÜV approval), EN1088,

GS-ET-19 (TÜV approval),

UL508 (UL recognition),

CSA C22 .2 No . 14 (c-UL recognized)

IEC60204-1/EN60204-1

(applicable standards for use)

Operating

Temperature

-25 to +70°C (No freezing)

Relative Humidity

45 to 85% (No condensation)

Storage Temperature

-40 to +80°C (No freezing)

Pollution Degree

3

Impulse Withstand

Voltage

2 .5 kV

Insulation Resistance

(500V DC megger)

Between live and dead metal parts: 100 MΩ

minimum (500V DC megger)

Between live metal part and ground:

100 MΩ minimum (500V DC megger)

Between live metal parts:

100 MΩ minimum (500V DC megger)

Between terminals of the same pole:

100 MΩ minimum

Electric Shock Class

Class II (IEC61140)

Degree of Protection

IP65 (IEC60529)

Shock Resistance

Operating extremes: 100 m/s

2

Damage limits:

1,000 m/s

2

Vibration Resistance

Operating extremes:

10 to 55 Hz, amplitude 0 .35 mm

Damage limits: 30 Hz, amplitude 1 .5 mm

Actuator Operating

Speed

0 .05 to 1 .0 m/s

Direct Opening Travel

Actuator HS9Z-A51: 11 mm minimum

Actuator HS9Z-A51A/A52/A52A/A53/A55: 12 mm

minimum

Direct Opening Force

80N minimum

Actuator Retention

Force (Note 1)

1,400N minimum (GS-ET-19)

Operating Frequency

900 operations per hour

Rear Unlocking

Button Mechanical

Durability

3,000 operations minimum (HS5E-K

L)

Mechanical Durability

1,000,000 operations minimum (GS-ET-19)

Electrical Durability

100,000 operations minimum (AC-12, 250V, 1A)

1,000,000 operations minimum (24V AC/DC, 100

mA)

(Operating frequency: 900 operations per hour)

Performance between

41 and 42 when head

is removed

Mechanical durability: 10 operations minimum

Insulation resistance: 100 M

Ω

(initial value)

Withstand voltage: 1,000V for 1 minute (initial value)

Conditional Short-

circuit Current

50A (250V) (Note 2)

Cable

UL2464, No . 22 AWG

(12-core, 0 .3 mm

2

or equivalent/core)

Cable Diameter

ø7 .6 mm

Weight (approx .)

510g (3m cable), 680g (5m cable)

Note 1: See page 61 for actuator retention force .

Note 2: Use 250V/10A fast-blow fuse for short-circuit protection .

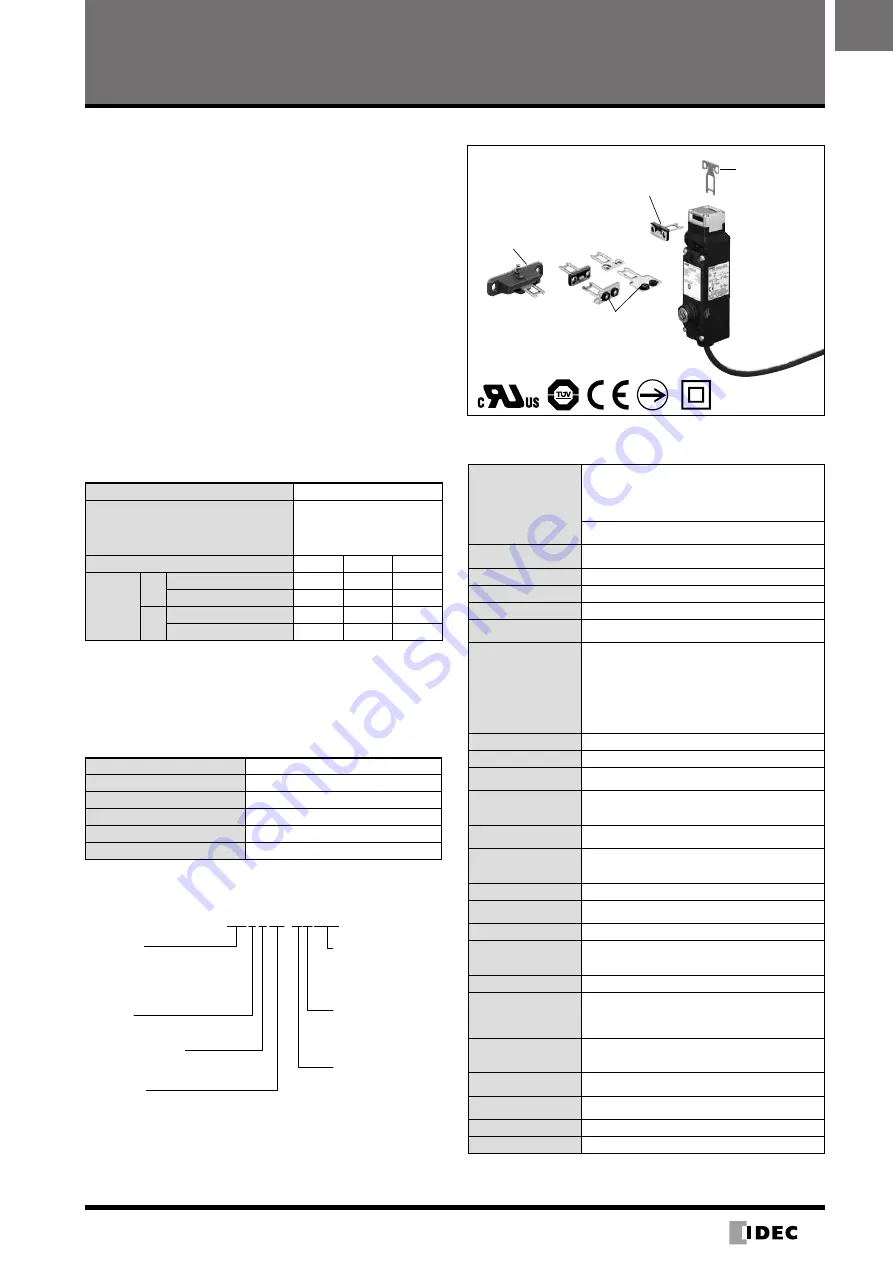

New interlock switches that can be locked and unlocked with a key.

•

Head removal detection circuitry .

•

High-security pin tumbler key is used . Sixteen types of key

numbers are available .

•

Available with rear unlocking button for emergency escape .

•

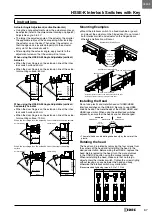

Accessory available for aluminum frame mounting .

•

Gold-plated contacts .

•

The locking strength is 1400N minimum . (GS-ET-19)

•

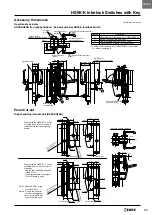

The head orientation can be rotated, allowing 8 different

actuator entries .

•

Metal actuator entry slot ensures high durability .

•

Actuator with rubber bushings alleviates the impact of

the actuator entry slot .

•

Environmentally-friendly . RoHs directive compliant .

•

Double insulation structure . No need for grounding .

•

Compact body: 35 × 40 × 146 mm

Right-angle Actuator

(SUS304)

Straight

Actuator

Right-angle Actuator

w/rubber bushings

Angle Adjustable

Actuator (vertical)

HS5E-K