69

HS5E-K Interlock Switches with Key

Instructions

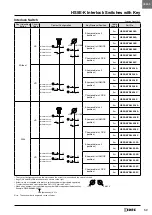

Manual Unlocking using the Rear Unlock-

ing Button

•

The rear unlocking button is used by the operator confined

in a hazardous area for emergency escape .

Unlock

Rear Unlocking Button

Unlock

Rear Unlocking

Button Kit

How to operate

•

When the rear unlocking button is pressed, the interlock

switch is unlocked and the door can be opened .

•

To lock the interlock switch, pull back the button .

•

When the button remains pressed, the interlock switch

cannot be locked even if the door is closed, and the main

circuit remains open .

Safety Precautions

•

Install the rear unlocking button in a place where only the

operator inside the hazardous area can use it . Do not

install the button in a place where an operator outside the

hazardous area can use it, otherwise the interlock switch

may be unlocked during usual machine operation, causing

danger .

•

Operate the rear unlocking button by hand only . Do not

operate using a tool or with excessive force . Do not apply

force to the button from the direction other than the proper

direction, otherwise the button will be damaged .

Recommended Tightening Torque for

Mounting Screws

•

HS5E-K interlock switch: 1 .8 to 2 .2 N·m (four M4 screws)

(Note)

•

Rear unlocking button: 0 .5 to 0 .7 N·m

•

Rear unlocking button kit: 4 .8 to 5 .2 N·m (M5 Screw)

•

Actuators

HS9Z-A51:

1 .8 to 2 .2 N·m (two M4 screws) (Note)

HS9Z-A52:

0 .8 to 1 .2 N·m (two M4 Phillips screws)

HS9Z-A51A/A52A: 1 .0 to 1 .5 N·m (two M4 screws) (Note)

HS9Z-A53:

4 .5 to 5 .5 N·m (two M6 screws) (Note)

HS9Z-A55:

1 .0 to 1 .5 N·m (two M4 screws) (Note)

Note: The above recommended tightening torques of the

mounting screws are the values confirmed with hex socket

head bolts . When other screws are used and tightened to a

smaller torque, make sure that the screws do not become

loose after mounting .

•

Mounting bolts must be provided by the users .

•

To avoid unauthorized or unintended removal of the in-

terlock switch and the actuator, it is recommended that

the interlock switch and actuator are installed in a secure

manner, for example using special screws or welding the

screws .

•

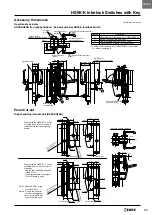

When installing the HS9Z-A51A and HS9Z-A52A actua-

tors, use the washer (supplied with the actuator) on the

hinged door, and mount tightly using two M4 screws .

M4 Screw Hole

Hinged Door

Note: Choose mounting centers of

either 12 mm or 20 mm.

M4 Screw

Rubber Bushing

Washer

Cables

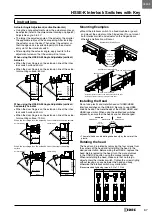

•

Do not fasten or loosen the gland at

the bottom of the interlock switch .

•

When bending the cable during wir-

ing, make sure that the cable radius

is kept at 30 mm minimum .

•

When wiring, make sure that water

or oil does not enter the cable .

•

Do not open the lid of the interlock

switch . Otherwise the interlock

switch will be damaged .

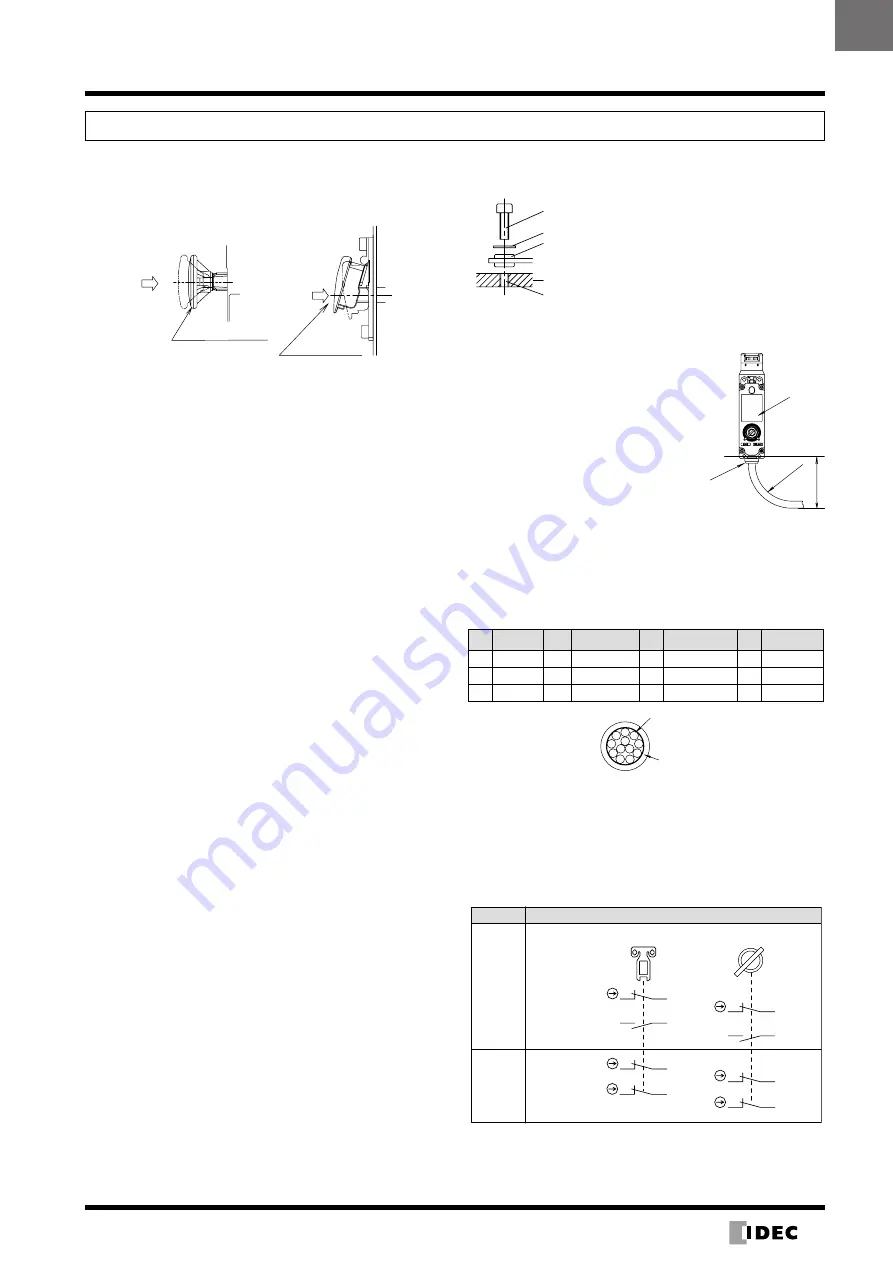

Wire Identification

•

Wires can be identified by color and white line printed on

the wire .

•

Wires whose colors are white, black, gray and gray/white

cannot be used .

No . Insulation No .

Insulation

No .

Insulation

No .

Insulation

1 White

4

Blue

7 Blue/White

10 Pink/White

2 Black

5

Brown/White

8 Orange/White

11 Gray

3 Brown

6

Orange

9 Pink

12 Gray/White

Jacket

Insulation

2

1

10

12

9 11

8

7

6

4

3

5

Circuit Code Identification

•

Circuit codes can be identified by the insulation color in

each contact configuration .

•

The following table shows the identification of circuit

numbers .

•

When wiring, cut unnecessary wires such as the dummy

insulation (white) and any unused wires .

Door Monitor

HS5E-KVA

HS5E-KVD

11

12

42

41

52

51

53

54

41

42

12

23

11

24

Contact Configuration

Model

LOCK

UNLOCK

22

21

Monitor Circuit: Blue

Monitor Circuit: Orange

Monitor Circuit:

Monitor Circuit:

Monitor Circuit: Blue

Monitor Circuit: Orange

Monitor Circuit:

Monitor Circuit:

Orange/White

Brown

Pink

Brown

Pink

Blue/White

Orange/White

Blue/White

Pink/White

Brown/White

Pink/White

Brown/White

• The contact configuration shows the status where the actuator is

inserted and the switch is locked .

30 mm

Gland

Minimum

Radius

Lid

(48)

HS5E-K