11

HT3P Safety Commander

™

Turn off the power before installation, removal, wiring, maintenance, and inspection. Failure to turn power off may cause electrical shock or fire

hazard.

Safety Precautions

Be sure to read the instruction sheet before installation, wiring, operation, and maintenance of the product.

For details on installation, wiring, and maintenance, see the Instruction sheet and

User’s Manual from the URL below.

URL: https://product.idec.com/?product=HT3P

• When using the HT3P in applications which require high level of

safety, add a fail-safe or backup functionality, and verify an adequate

level of safety using the product specifications.

• Turn off the power to the HT3P before installation, removal, wiring,

maintenance, and inspection of HT3P.Failure to turn power off may

cause electrical shock or fire hazard.

• Special expertise is required to install and wire the HT3P. Users

without such expertise must not perform installation or wiring.

• An emergency circuit must be configured outside of the HT3P by

using the emergency stop switch mounted on HT3P unit.

• Connect the emergency stop switch and the enabling switch on

the HT3P to function as either a category 0 or category 1 stop in

accordance with IEC/EN60204-1.

• Do not, under any circumstances, hold the enabling switch on the

HT3P in position 2 with tape, string, or deform the rubber cover. The

intrinsic function of the enabling switch will be lost, and the enabling

switch may not work in case of an emergency situation.

• When using the HT3P, place your finger firmly on the enabling switch.

• Perform regular checks to confirm that the emergency stop switch

and enabling switch work properly. It is extremely dangerous if the

enabling switch no longer returns to position 1 due to a foreign object

becoming lodged in the switch because position 2 will be maintained

even when you remove your hand.

• The enable functionality must be evaluated with the robot.

• Stop using the HT3P if it is accidentally dropped or exposed to

significant shocks, check for damage, and confirm that its various

functions work safely and correctly.

• Malfunction may result due to noise. Follow the instructions below

– Set the FE terminals to class D grounding

(Class 3 grounding : Grounding resistance: 100Ω or less).

– Do not connect the grounding conductor to the grounding conductor

of the power unit.

Do not supply power to the USB with foreign matter or water on the

product.

• Do not pull or apply load to the cable, USB cable, or the connector.

Otherwise, fire or malfunction may occur.

• Use a dedicated optional neck strap. Be careful not to get neck straps

getting caught in machines during operation.

• Use the emergency stop switch indicator LED to determine whether

the emergency stop switch is enabled or disabled. When the product

is disconnected from the control device (when the emergency stop

switch is disabled), make sure to store the product where it is not

accessible to the operator so that it will not accidentally be operated.

• HT3P is designed for indoor use only (Not for outdoor use)

• Do not apply strong shock such as dropping the HT3P. Otherwise

damage or malfunction will result.

• Use of the product in high temperature or high-humidity

environments, or in locations where it is exposed to condensation,

corrosive gas or large shock loads, can create the risk of electric

shock or fire.

• HT3P is designed for use in pollution degree 3 environment. Use the

HT3P under pollution degree 3 environment. (according to IEC60664-

1 rating)

• Be sure to prevent metal fragments or wire chips from dropping

inside the HT3P housing. Ingress of such fragments and chips may

cause fire hazard, damage, and malfunction.

• Use a power supply of the rated value. Using a wrong power supply

or wiring in reverse polarity may cause fire hazard and damage.

• Make sure of safety before starting and stopping HT3P. Incorrect

operation of HT3P may cause mechanical damage or accidents.

• Do not attempt to disassemble, repair or modify HT3P. This can create

the risk of fire or electrical shock.

• When disposing of HT3P, do so as an industrial waste.

• Install according to the instructions. Improper installation may result

in, failure, electrical shock, fire hazard, or malfunction.

• Use the HT3P only for its intended purpose. Otherwise functions of

the product may be impaired.

• Please note that some tablets may interfere with power or volume

buttons at installation.

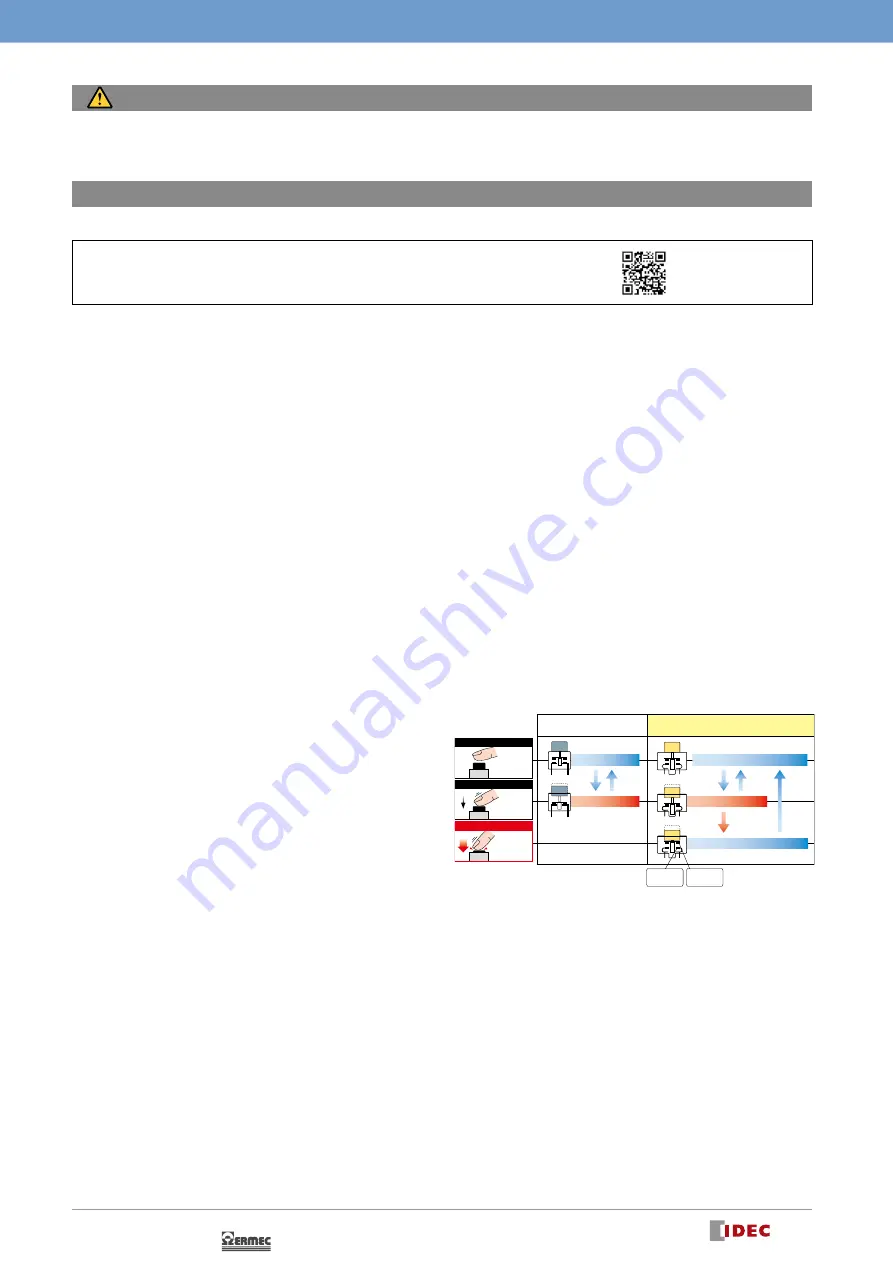

3-position operation of enabling switch

Terminal

Contact

Movable

Contact

Position 1

General Pushbutton Switch

(2-position)

3-position Enabling Switch

OFF

OFF

ON

OFF

ON

No position

1. Press

1. Press

lightly

3. Press

fully

4. Release

2. Release

2. Release

Button

released

Position 2

Button

pressed

Position 3

Button

pressed

fully

Instructions

Tel. +34 902 450 160

Tel. +34 902 450 160

info@ermec.com

info@ermec.com

www.ermec.com

www.ermec.com

ERMEC, S.L. BARCELONA

ERMEC, S.L. BARCELONA

C/ Francesc Teixidó, 22

C/ Francesc Teixidó, 22

08918 Badalona SPAIN

08918 Badalona SPAIN

ERMEC, S.L. - MADRID

ERMEC, S.L. - MADRID

C/ Puerto Rico, 4

C/ Puerto Rico, 4

28222 Majadahonda (Madrid) SPAIN

28222 Majadahonda (Madrid) SPAIN

bilbao

@ermec.com

bilbao

@ermec.com

portugal

@ermec.com

portugal

@ermec.com