21: T

RIGONOMETRIC

F

UNCTION

I

NSTRUCTIONS

21-2

FC6A S

ERIES

MICROS

MART

L

ADDER

P

ROGRAMMING

M

ANUAL

FC9Y-B1726

DEG (Radian to Degree)

Valid Devices

For valid device address ranges, see "Device Addresses" on page 2-1.

When the conversion result is not within the range between –3.402823

×

10

38

and –1.175495

×

10

–38

or between 1.175495

×

10

–38

and

3.402823

×

10

38

, special internal relay M8003 (carry or borrow) is turned on except when the conversion result is 0. When the conversion result is

below –3.402823

×

10

38

or over 3.402823

×

10

38

, causing an overflow, the destination device designated by D1 stores a value of minus or plus

infinity.

When the data designated by S1 does not comply with the normal floating-point format, a user program execution error will result, turning on

special internal relay M8004 and ERR LED on the FC6A Series MICROSmart. For details about the user program execution errors, see "User Program

Execution Errors" on page 3-10.

Since the DEG instruction is executed in each scan while input is on, a pulse input from a SOTU or SOTD instruction should be used.

Valid Data Types

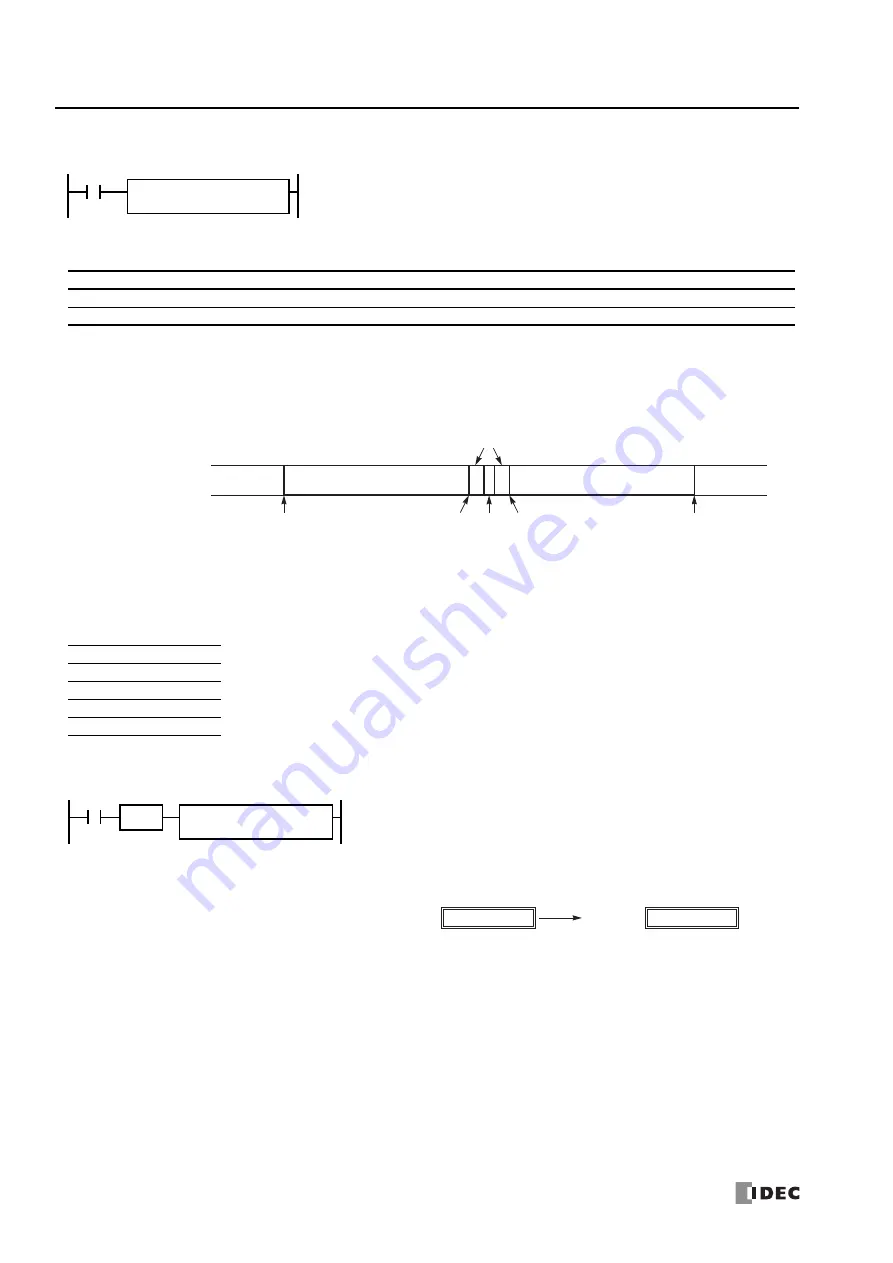

Example: DEG

S1·S1+1 rad

×

180/

π

→

D1·D1+1°

When input is on, the radian value assigned by source device S1 is converted into a degree value

and stored to the destination assigned by device D1.

DEG(F)

S1

*****

D1

*****

Device

Function

I

Q

M

R

T

C

D

P

Constant

Repeat

S1 (Source 1)

Radian value to convert into degree

—

—

—

—

—

—

X

—

X

—

D1 (Destination 1)

Destination to store conversion results

—

—

—

—

—

—

X

—

—

—

0

–1.175495

×

10

–38

M8003

1

1

1.175495

×

10

–38

0

–3.402823

×

10

38

0

Execution Result

1

Overflow

0

1

3.402823

×

10

38

Overflow

Not Zero

W (word)

—

Since floating point data is used, the source and destination devices use two consecutive data registers.

I (integer)

—

D (double word)

—

L (long)

—

F (float)

X

When input I1 is turned on, the radian value of data registers D10 and D11 assigned by

source device S1 is converted into a degree value and stored to data registers D20 and

D21 assigned by destination device D1.

I1

S1

D10

DEG(F)

D1

D20

SOTU

4.712389 rad

×

180/

π

→

270.0°

D1

S1

4.712389

D10·D11

270.0

D20·D21

Summary of Contents for MICROSmart FC6A Series

Page 1: ...B 1726 7 FC6A SERIES Ladder Programming Manual ...

Page 8: ...Preface 7 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 32: ...1 OPERATION BASICS 1 20 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 96: ...3 INSTRUCTIONS REFERENCE 3 18 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 130: ...4 BASIC INSTRUCTIONS 4 34 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 192: ...9 SHIFT ROTATE INSTRUCTIONS 9 12 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 272: ...12 DISPLAY INSTRUCTIONS 12 24 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 284: ...14 REFRESH INSTRUCTIONS 14 6 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 502: ...25 DATA LOG INSTRUCTIONS 25 22 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 546: ...26 SCRIPT 26 44 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...

Page 598: ...APPENDIX A 14 FC6A SERIES MICROSMART LADDER PROGRAMMING MANUAL FC9Y B1726 ...