185

800-262-IDEC

(4332)

•

USA & Canada

SA1E

Sensors

OI T

ouchscreens

PLCs

Automation Software

Power Supplies

Sensors

Communication

Barriers

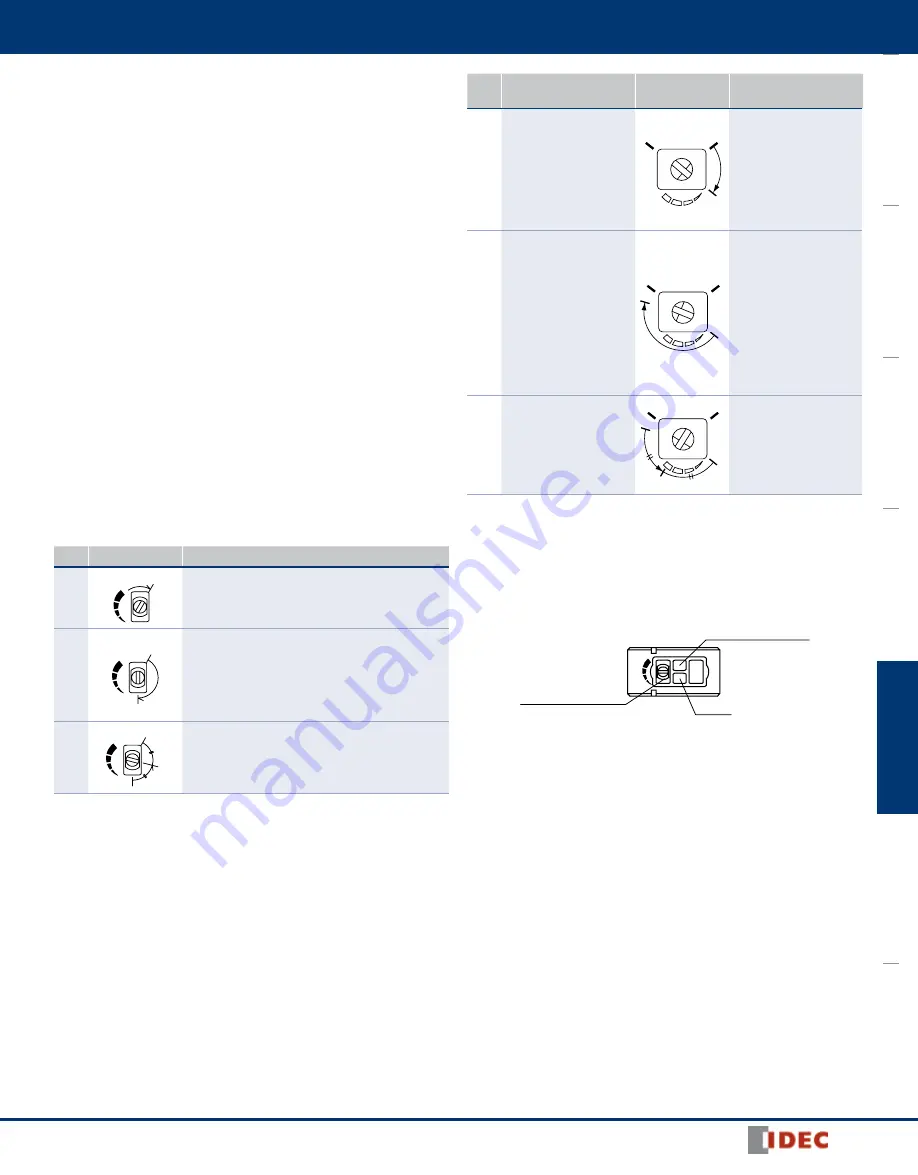

3. Sensitivity Adjustment

•

Referring to the table to the right, adjust the sensitivity of the SA1E photo-

electric switch when necessary, in such cases as the through-beam type is

used to detect small or translucent objects or the reflective type is affected by

background. The table explains the status of operation LED when the opera-

tion mode is set to light ON.

•

After adjusting the sensitivity, make sure that stable LED turns on at stable

incident and stable interruption. For detecting objects too small to turn on the

stable LED, use an optional slit.

•

Sensitivity is set to the maximum at the factory before shipment. When

adjusting the sensitivity, use the screwdriver supplied with the SA1E photo-

electric switch to turn the control as shown below, to a torque of 0.05 N·m

maximum.

Step

Photoelectric

Switch Status

Sensitivity

Control

Adjusting Procedure

1

Receiving light

•

Through-beam, polarized

reflective: No object

detected

•

Diffuse reflective,

small-beam reflec tive,

convergent reflective:

Object detected

max.

min.

A

Turn the control counter-

clockwise to the mini mum.

Then turn clock wise until

the operation LED turns

on (turns off with dark ON

type) (point A).

2

Light is interrupted

•

Through-beam, polar-

ized reflective: Object

detected

•

Diffuse reflective,

small-beam reflec tive,

convergent reflective:

No object detected

B

A

max.

min.

At interruption status, turn

the control clock wise from

point A, until the operation

LED turns on (turns off with

dark ON type) (point B).

If the operation LED does

not turn on (turn off with

dark ON type) even though

the control has reached the

maxi mum, set the maxi-

mum position as point B.

3

–

C

B

A

max.

min.

Set the middle point

between point A and B as

point C.

4. Adjustment of Sensing Range for Background Suppression (BGS) Type

•

When adjusting the sensing range, follow the instructions below.

Step Distance Control

Adjusting Procedure

1

A

Turn the control counter-clockwise to the mini mum. Then

turn clock wise until the operation LED turns on (turns off

with dark ON type) (point A).

2

A

B

At interruption status, turn the control clock wise from

point A, until the operation LED turns on (turns off with

dark ON type) (point B).

If the operation LED does not turn on (turn off with dark

ON type) even though the control has reached the maxi-

mum, set the maximum position as point B.

3

A

B

C

Set the middle point between point A and B as point C.

1. When the background is far off and not detected, turn the control 360°, and set the point as point C.

2. Because the control is multi-turn, it may take more than one turn to move from point A to point B.

3. Turning the control clockwise lengthens the sensing dis tance.

4. Background suppression (BGS) type is not provided with a stable LED.

Operation LED (yellow)

(Note 3)

Sensing Range Control

(6-turn)

(Note 4)

5. Power Supply and Wiring

•

Do not use the SA1E photoelectric switch at the transient status immediately

after turning on the power (approx. 100 ms, back ground suppression type: 200

ms). When the load and switch use different power supplies, make sure to

power up the switch first.

•

Use a power supply with little noise and inrush current, and use the photo-

electric switch within the rated voltage range. Make sure that ripple factor is

within the allowable limit. Do not apply AC volt age, otherwise the switch may

blow out or burn.

•

When using a switching power supply, make sure to ground the FG (frame

ground) terminal, otherwise high-frequency noise may affect the photoelectric

switch.

•

Turn power off before inserting/removing the connector on photo electric

switch. Make sure that excessive mechanical force is not applied to the

connector. Connect the connector cable to a tight ening torque of 0.5 N·m

maximum.

•

To ensure the degree of protection, use the applicable connector cable for the

connector type. Connector cables are ordered sepa rately.

•

Avoid parallel wiring with high-voltage or power lines in the same conduit,

otherwise noise may cause malfunction and damage. When wiring is long,

use a separate conduit for wiring.

•

Use a cable of 0.3 mm

2

minimum core wires, then the cable can be extended

up to 100m.