3 HG4G/3G, HG2G-5F

35-46

WindO/I-NV4 User’s Manual

3.7 Installation

●

Operating Environment

For designed performance and safety of the HG4G/3G, HG2G-5F, do not install the HG4G/3G, HG2G-5F in the

following environments:

• Where dust, briny air, or iron particles exist.

• Where oil or chemical splashes for a long time.

• Where space is filled with oil mist.

• Where direct sunlight falls on the HG4G/3G, HG2G-5F.

• Where strong ultraviolet rays fall on the HG4G/3G, HG2G-5F.

• Where corrosive or combustible gasses exist.

• Where the HG4G/3G, HG2G-5F is subjected to shocks or vibrations.

• Where condensation occurs due to rapid temperature change.

• Where high-voltage or arc-generating equipment (electromagnetic contactors or circuit protectors) exists in the vicinity.

●

Ambient Temperature

• Allow sufficient space for ventilation, and install the equipment away from heat sources.

• Allow at least 100mm between the HG4G/3G, HG2G-5F and walls or other equipment.

• Do not install the HG4G/3G, HG2G-5F where the ambient temperature exceeds the rated operating ambient

temperature range. When mounting the HG4G/3G, HG2G-5F in such locations, provide a forced air-cooling fan or

air-conditioner to keep the ambient temperature within the rated temperature range.

• The HG4G/3G, HG2G-5F is designed to install on a vertical plane so that natural air-cooling is provided. If you

install it using any other orientation, use forced-air cooling, or lower the ambient operating temperature.

●

HG4G/3G, HG2G-5F Installation

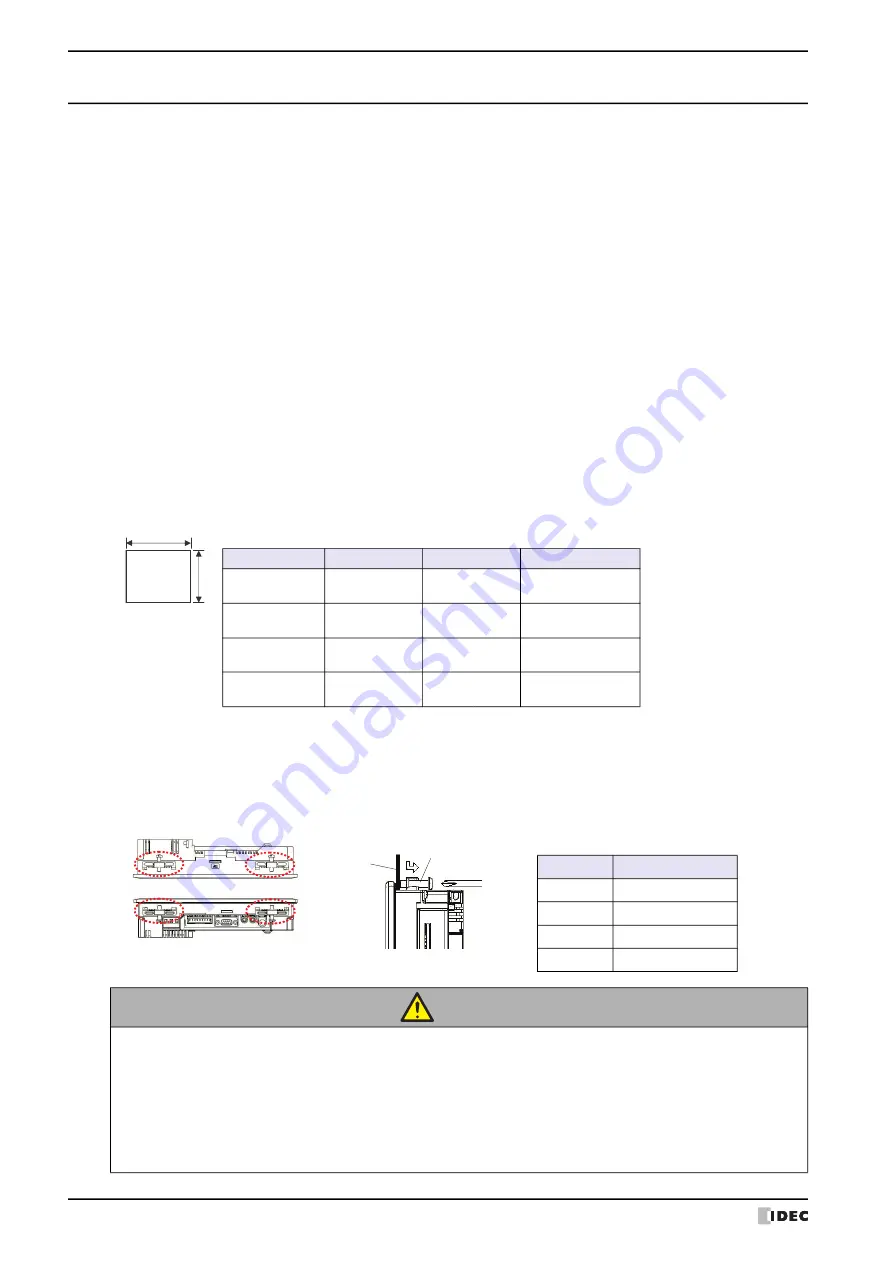

• Make a panel cut-out on the panel with the dimensions shown below.

• Use the attached mounting clips to tighten the screws evenly to mount panel: screws must be applied on total of

four places on top and bottom with the specified torque.

Mounting clips can be attached to the left and right sides of HG4G and HG2G-5F. However, if they are attached in

such way, there is a risk of not satisfying product specifications such as waterproof performance, shock resistance,

and vibration resistance performance.

Mounting Clip Position ex) HG3G-8 (8.4 inch)

CAUTION

• Do not tighten with excessive force, otherwise the HG4G/3G, HG2G-5F may warp and cause

wrinkle on the display, or impair the waterproof characteristics.

• If the mounting clips are tightened obliquely to the panel, the HG4G/3G, HG2G-5F may fall off the

panel.

• When installing the HG4G/3G, HG2G-5F into a panel cut-out, make sure that the gasket is not

twisted. Especially when re-installing, take special care because any twists in the gasket will

impair the waterproof characteristics.

B

A

Unit: mm

Type No.

A

B

Panel Thickness

HG4G

227.5

+2.0

0

301.5

+2.0

0

2.0 to 5.0

HG3G-A

200.0

+2.0

0

258.0

+2.0

0

2.0 to 5.0

HG3G-8

164.0

+2.0

0

219.0

+2.0

0

2.0 to 5.0

HG2G-5F

121.0

+2.0

0

153.0

+2.0

0

1.6 to 5.0

TOP

Panel

BOTTOM

Mounting

Clip

Unit : N∙m

Type

Specified Torque

HG4G

0.5 to 0.6

HG3G-A

0.5 to 0.6

HG3G-8

0.5 to 0.6

HG2G-5F

0.2 to 0.3

Summary of Contents for WindO/I-NV4

Page 1: ...B 1701 16 User s Manual...

Page 108: ...5 WindO I NV4 Common Operations and Settings 2 76 WindO I NV4 User s Manual...

Page 256: ...7 BACnet Communication 3 148 WindO I NV4 User s Manual...

Page 372: ...6 Screen Restrictions 5 32 WindO I NV4 User s Manual...

Page 390: ...5 Part Library Function 6 18 WindO I NV4 User s Manual...

Page 420: ...3 Text 7 30 WindO I NV4 User s Manual...

Page 628: ...2 Multi State Lamp 9 34 WindO I NV4 User s Manual...

Page 924: ...4 Meter 11 76 WindO I NV4 User s Manual...

Page 990: ...7 Timer 12 66 WindO I NV4 User s Manual...

Page 1030: ...4 Using Data and Detected Alarms 13 40 WindO I NV4 User s Manual...

Page 1098: ...4 Using the Data 15 22 WindO I NV4 User s Manual...

Page 1248: ...5 Restrictions 22 18 WindO I NV4 User s Manual...

Page 1370: ...2 Monitoring on the MICRO I 25 28 WindO I NV4 User s Manual...

Page 1388: ...4 Restrictions 26 18 WindO I NV4 User s Manual...

Page 1546: ...5 Module Configuration Dialog Box 30 36 WindO I NV4 User s Manual...

Page 1614: ...3 Settings 34 14 WindO I NV4 User s Manual...

Page 1726: ...5 Text Alignment A 10 WindO I NV4 User s Manual...