2

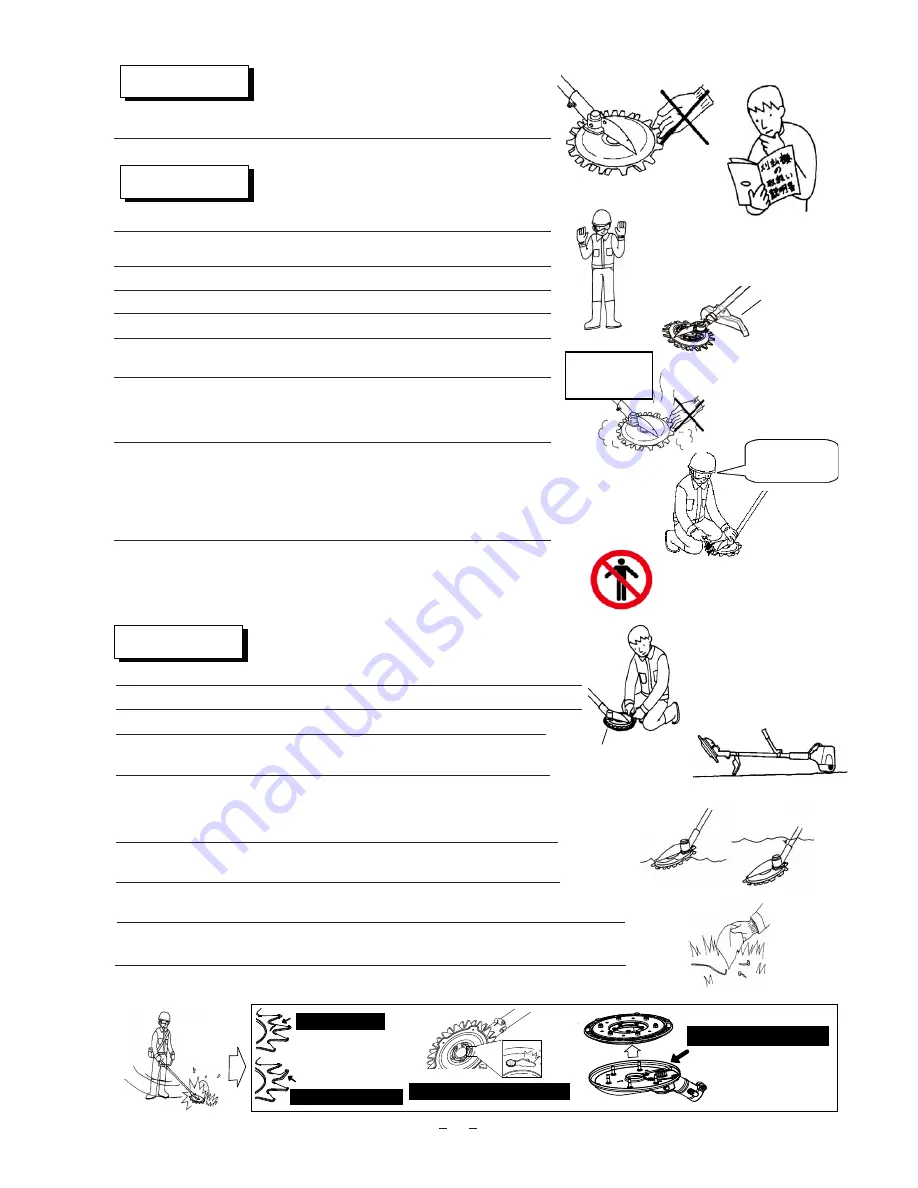

Protector

protective cover

15m

DANGER!

Be careful not to touch the blades. The blades are sharp and

may cause serious injury.

Read the manual of the brushcutter in advance.

WARNING!

Wear safety glasses while using the Power Rotary Scissors.

Be very careful of the blades.

Wear gloves when handling the Power Rotary Scissors.

Wear protective clothing for grass cutting work.

Wear sturdy boots with nonslip soles.

Be sure to attach the protector in the brushcutter.

Never use the Power Rotary Scissors after consumption of alcohol or

drugs, or if feeling tired or ill.

Allow the Power Rotary Scissors to cool sufficiently after operation,

before you touch it.

The Power Rotary Scissors heats up during operation due to the friction

of the blade.

Stop the

engine first

If a foreign object, such as a piece of wire becomes tangled in the Power

Rotary Scissors stopping blade rotation, stop the engine first before

removing the object.

If blade rotation is still not smooth after removing the object, see the

“Maintenance” section of this manual (Page 8) for further troublesooting

information.

This product can reduce a flying stones. It does not mean not to fly at all.

Make sure the safety confirmation to the surroundings and wear safety glasses while using.

Please make sure that there are no children or other people within a working

range of 15 meters, also pay attention to any animals in the working vicinity.

ATTENTION

!

Use only for lawn and grass cutting.

To avoid malfunction or injury do not modify your Power Rotary Scissors.

Shield the blades with the protective cover when not in use.

The blades must be free and not touch anything while starting the

brushcutter engine.

Blades off the

ground for starting!

Obstacles like plastic bags and steel wires in the grass should be removed

before cutting the grass to prevent them from becoming entangled in the blades.

Periodically lubricate the Power Rotary Scissors to ensure proper performance

(See page 9).

The Power Rotary Scissors is water resistant. However, if it is used

in a wet area, wipe the blades and lubricate after each use.

Do not completely submerge the Power Rotary Scissors and the

brushcutter in water.

Sharpen the blades if grass cutting efficiency drops.

See sharpening (page 6), maintenance (page 8).

Danger!

Very Hot!

No!

Do not hit the blade against obstacles. It will be caused damage to each part .

Also, there is a possibility that the blade and the bottom disk drop off, which is dangerous.

Cracking of the blade

Deformation of the blade

Damage of the bottom disk fixing parts

Damage of the drive pinion gear

No!

OK!

Summary of Contents for ASK-VW23

Page 7: ...6 9 ...