FD151 Gas Compressor 15

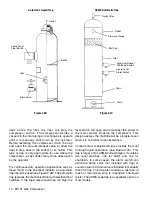

3.3 CRANKCASE OIL PRESSURE

ADJUSTMENT

Your Corken compressor Model FD151 is

equipped with an automatically reversible

geartype oil pump. Ensure that the pumping

system is primed and the oil pressure is properly

adjusted to assure smooth operation.

Before starting your compressor, check and fill the

compressor crankcase with the proper quantity of

lubricating oil.

To assure critical lubrication of crossheads and

crosshead guide during the initial start-up period:

• Remove inspection plate from crosshead guide.

• Fill crankcase with lubricating oil through the

inspection

plate opening (Figure 2.6C).

• Allow the oil to lubricate the crossheads and guide

as it fills into the crankcase.

• Check crankcase oil level at the oil bayonet. (Re-

install the inspection plate and gasket.)

• Follow any other pre-start-up procedures that may

be necessary in your application.

• Double-check the crankcase oil level.

• Start compressor, observing the crankcase oil

pressure gauge. If oil-pressure gauge does not

register 20 - 30 PSIG after 30 seconds, stop the

unit. Refer to Trouble-Shooting Guide in Appendix

J. Consult the Factory if condition cannot be

corrected.

DO NOT continue to run the

compressor without the correct oil pressure.

The oil pressure should be about 20 psi (2.4 Bars)

minimum for normal service. If the discharge

pressure is above 200 psi (14.8 Bars) or if the

compressor is equipped with a hydraulic unloader

(Specification 7 or 78; see Figure 3.4A), the oil

pressure must be maintained at a minimum of 25

psi (2.7 Bars). The oil pressure is regulated by a

spring-loaded relief valve mounted on the bearing

housing opposite the flywheel. As shown in Figure

3.3A, turn the adjusting screw clockwise to increase

the oil pressure, counterclockwise to lower it. Be

sure to loosen the adjusting-screw lock nut before

making any adjustments. Tighten locknut back after

any adjustments.

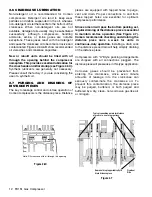

3.4 ADJUSTMENT OF MECHANICAL

UNLOADER CONTROLS

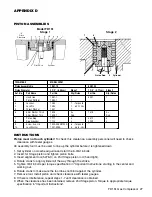

NOTE: If your compressor is not equipped with

mechanical unloader control (valve/ unloader Spec.

7, 78, and 8; see Appendix A to determine if this

applies to your machine), proceed to Section 3.5. See

Section 1.7 for explanation on how suction valve

unloaders work.

Figure 3.3a

Oil Pressure Adjustment

Oil Level Bayonet

Full

Low

Oil

Pressure

Gauge

Oil

Pump

Cover

Lock Nut

Oil Pressure

Adjusting Screw