16 FD151 Gas Compressor

3.5 STARTUP CHECK LIST

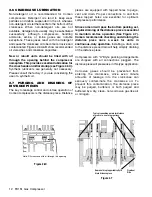

Please verify all of the items on this list before

starting your compressor! Failure to do so may

result in a costly (or dangerous) mistake.

BEFORE STARTING THE COMPRESSOR:

1. Become familiar with the function of all piping

associated with the compressor. Know each line's

use!

2. Verify that actual operating conditions will match

anticipated conditions.

3. Ensure that line pressures are within cylinder-

pressure ratings.

4. Clean out all piping.

5. Check that distance piece vents are tubed or

plugged as desired.

6. Check all mounting shims, cylinder and piping

supports to ensure that no undue twisting forces

exist on the compressor.

7. Verify that strainer elements are in place and

clean.

8. Verify that cylinder bore and valve areas are

clean.

9. Check V-belt tension and alignment. Check drive

alignment on direct-drive units.

10.Rotate unit by hand. Check flywheel for wobble or

play.

11.Check crankcase oil level and all other fluid

levels (lubricator, radiator, oil reservoirs, etc.).

12.Drain all liquid traps, separators, etc.

13.Verify proper electrical supply to motor and panel.

14.Check that all gauges are at zero-level reading.

15.Test piping system for leaks.

16.Purge unit with air before pressurizing with gas.

17.Carefully check for any loose connections or

bolts.

18.Remove all stray objects (rags, tools, etc.) from

vicinity of unit.

19.Verify that all valves are open or closed as

required.

20.Double-check all of the above.

AFTER STARTING THE COMPRESSOR:

1. Verify and note proper oil pressure. Shut down

and correct any problem immediately.

2. Observe noise and vibration levels. Correct

immediately

if excessive.

3. Verify proper compressor speed.

4. Examine entire system for gas, oil or water leaks.

5. Note rotation direction.

6. Check start-up voltage drop, running amperage

and voltage at motor junction box (not at the

starter).

7. Verify proper lube rate (lubed units only).

8. Test each shut-down device and record set points.

9. Test all dump valves, relief valves and unloaders.

10.Check and record all temperatures, pressures

and volumes after 30 minutes and 1 hour.

11.After 2-5 hour of running time, check, retorque all

head bolts, valve hold-down screws, and

baseplate anchor bolts.