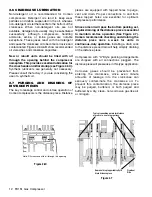

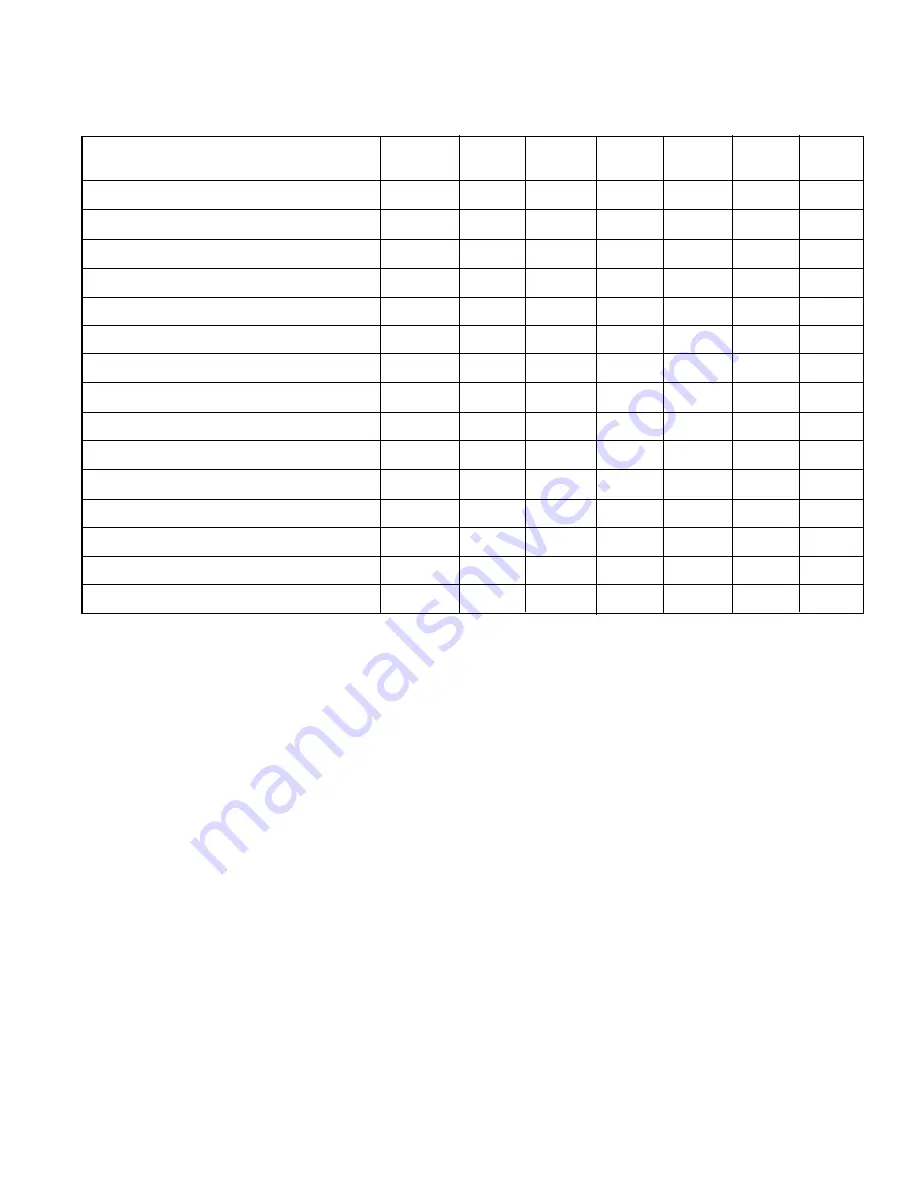

FD151 Gas Compressor 17

ITEM TO CHECK

First Week

Daily

Weekly

250

1000

2000

6000

Only

Hours

Hours

Hours

Hours

Crankcase oil pressure

X

Compressor suction pressure

X

Compressor discharge pressure

X

Compressor discharge temperature

X

Crankcase oil level

X

Drain liquid from system accumulation points

X

Drain / check distance piece

X

Check V-belts for correct tension

X

Retorque valve holddown screws

X(c)

X

Complete preventative maintanence

X(d)

Replace valve assemblies

X

Replace piston rings

X(a)

Replace packing rings

X

Change crankcase oil

X(b)

Complete Rebuild

X(e)

a.

Piston ring life varies greatly, depending on application, gas, and operating pressures. Consult factory for additional

recommendations for your specific applications and operating pressures. The initial set of piston rings may wear

faster than replacement rings. Piston ring life tends to get better as the ring material transfers into the cylinder wall

surfaces. On units with coated cylinders it is recommended to replace the initial piston rings after 1,000 hours.

b.

Change oil and filter every 250 hours of operation or every 45 days, whichever occurs first.

c.

Holddown screws must be checked at least once in the first 200 hours of operation.

d.

Includes rings, valves, packing and gaskets.

e.

All bearings, crossheads, rings, valves, packing and gaskets.

*

Recommended maintenance as suggested above are general guidelines only. Your specific maintenance

requirements may vary depending on the operating conditions and duty cycle.

CHAPTER FOUR

ROUTINE MAINTENANCE CHART