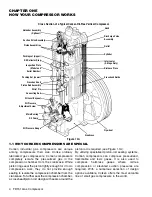

18 FD151 Gas Compressor

5.1 VALVES

CAUTION: Always relieve pressure in the unit

before attempting any repairs.

Low capacity, overheating, noise and vibration are all

indications of possible valve failure. Because valve

problems can manifest themselves in so many

different forms, valve inspection is frequently the best

first step in troubleshooting poor performance.

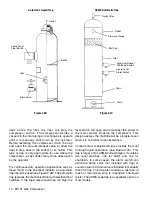

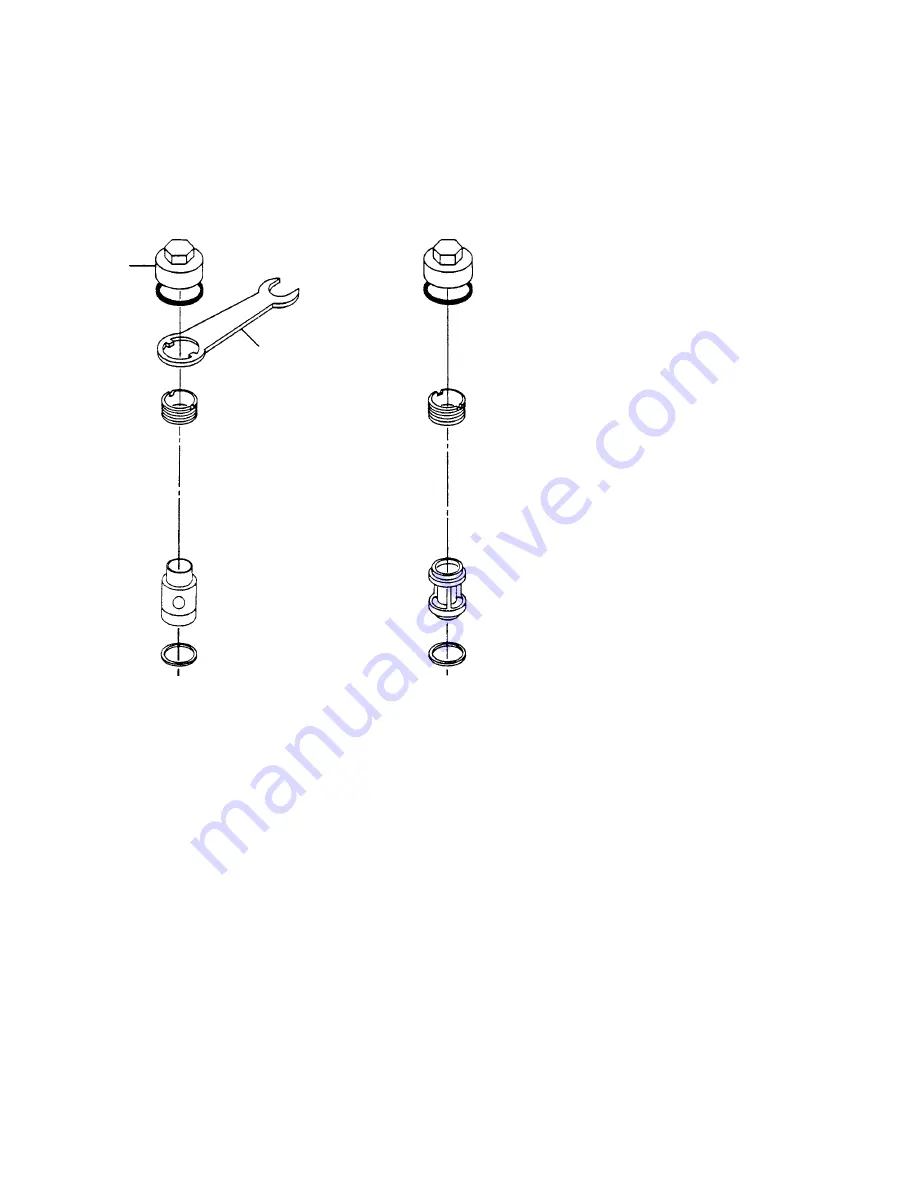

To remove and inspect valves,

begin by

depressurizing and purging

(if necessary) the unit.

Next, remove the valve cap or unloader assembly and

then remove the valve holddown screw (see Figure 5.1

A) with the special wrench supplied with the compressor.

Valves may then be removed.

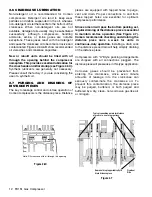

Inspect valves for breakage, corrosion, scratches on

the valve disk and debris. In many cases, valves may

simply be cleaned and reinstalled. If valves show any

damage, they should be repaired or replaced.

Replacement is usually preferable, although repair

parts are available. If valve disks are replaced, seats

should also be lapped until they are perfectly smooth.

If more than .005” must be removed to achieve a

smooth surface, the valve should be discarded. If

disks are replaced without relapping the seat, rapid

wear and leakage will occur.

Figure 5.1A

Compressor Model FD151

CHAPTER FIVE

ROUTINE SERVICE AND REPAIR PROCEDURES

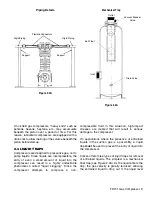

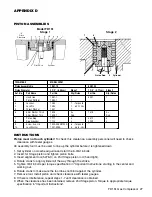

Suction:

Specification 4

Discharge:

All Specifications

* Older Units may have a metal gasket instead of the o-ring.

O-rings*

Corken Wrench

Valve Cap

Head

Head