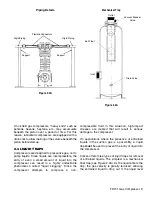

5.3A). Next, remove the roll pin with needle nose

pliers. The castellated nut may now be removed and

the piston platform lifted off the end of the piston rod.

Check the thrust washer and shims for damage and

replace if necessary. (FD151 Stage 1 only). See

Figure 5.4A Below.

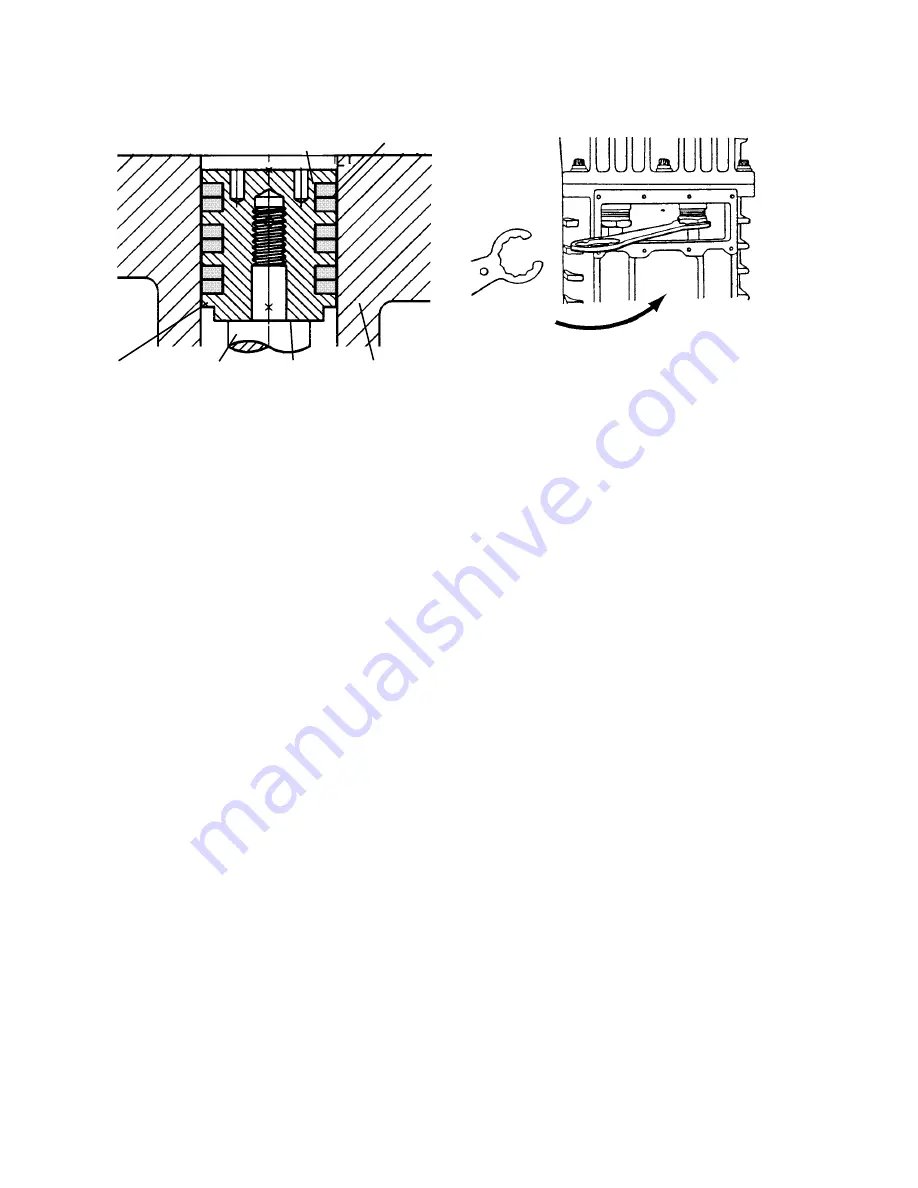

Remove the piston head by using spanner tool Pt. No.

5207-X. Turn piston counterclockwise to remove from

piston rod. Replace piston as noted below. On Model

FD151 (second stage) a roll pin and lock nut are not

used. A small amount of LOCTITE NO. 272 should be

applied to the threads on the piston rod prior to final

assembly of piston. Adjust piston clearance and torque

as noted in Appendix C and D.

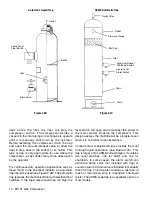

Reinstall the piston platform with the same thickness

of shims as before, BUT DO NOT REINSTALL THE

ROLL PIN. Replace the cylinder and install the

piston heads with new piston rings and expanders.

Now measure dimension “X”, shown in the

illustration. If this measurement does not fall within

the tolerances shown in Appendix D, remove the

piston, adjust the shims as necessary and

remeasure the “X” dimension. When the piston is

properly shimmed, tighten the castellated nut, as

shown in Appendix C. Now install a new roll pin to

lock the castellated piston nut in place. Install the

piston head and tighten the socket head bolts in an

alternating sequence. Reinstall the head and follow

standard start-up procedure.

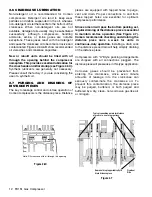

5.5 PISTON ROD PACKING

ADJUSTMENT

Piston-rod packing should be replaced whenever

leakage approaches an unacceptable level.

“Acceptable leakage” should be determined by the

customers according to safety and environmental

regulations for their area. Typically, it is a good idea

to replace piston-rod packing and piston rings at the

same time. Instructions for packing replacement are

included with each set of packing.

Inspection of the rod packing is generally not

productive, since packing that cannot be adjusted to

an “acceptable leakage” rate should be replaced.

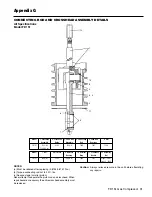

To adjust the packing, remove the compressor

nameplate, tighten the packing-adjusting nut(s) 1/4 turn

with the wrench supplied, then run the compressor a few

minutes to reseat the packing. If the leakage is still

unacceptable, tighten the adjusting nut as necessary,

1/4 turn at a time; do not over tighten! If the adjusting nut

is tightened until the packing spring is solid, the packing

should be replaced. If packing will not seal, carefully

inspect piston rods for possible scoring. Replace if

needed.

Reattach the compressor nameplate after adjustments

or repairs are made.

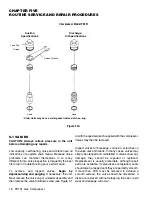

5.6 BEARING REPLACEMENT

To replace the crankcase roller bearings, wrist-pin

bushing and connecting-rod bearings, begin by

removing the head, cylinder, piston, crosshead guide

and crosshead. Drain the crankcase and remove the

inspection plates. Loosen and remove the

connecting-rod bolts in order to remove the

crosshead/connecting-rod assembly.

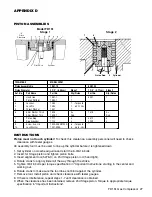

Figure 5.4B

Piston Cross-Section

Model FD151 (Second Stage)

Figure 5.5A

Packing-Adjusting Nuts

Piston Ring

Piston Ring

Expander

Piston Rod

Pistons

Shim Washer

Cylinder

“X” Piston

Clearance

Tighten 1/4 turn