22 FD151 Gas Compressor

Bearing - Carrier Replacement

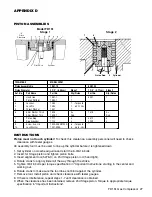

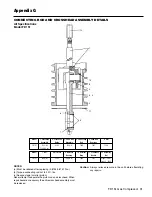

Figure 5.7A

To check the crankshaft end play, first remove the oil

pump (see Section 5.7). Press the end of shaft

towards the crankcase; if a clicking noise or motion

is detected, the crankshaft has too much end play. To

reduce end play, remove the bearing cover and

remove a thin shim. Recheck the end play after

replacing the bearing cover. When there is no

detectable end play, the shaft must still be able to

rotate freely. If the shaft sticks, binds or becomes

abnormally warm, the crankshaft bearings are too

tight. If the shaft is too tight, add more shims but

make sure not to over-shim. (Appendix E lists the

proper crankshaft end play.)

When the shaft can be rotated freely by hand and

no end play is present, the rest of the compressor

may be reassembled. If the crankshaft roller

bearings are too tight or too loose, premature

bearing failure will result.

Reinstall the flywheel on the crankshaft and check

the runout as shown in Appendix E.

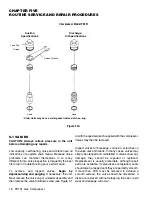

5.7 OIL PUMP INSPECTION

Damage to the oil pump may result if the compressor

operates for a prolonged period with dirty or

contaminated crankcase oil. To check the oil pump,

unbolt the pump cover and remove the oil pump,

spring guide, spring and oil-pump shaft, as shown in

Figure 5.7A. Inspect the gears in the oil pump for

corrosion or pitting and replace if necessary. Check

the oil-pump-shaft bushing in the bearing carrier. If

the bushing is corroded, pitted or worn, the oil-pump-

shaft bushing should be replaced.

Before reassembling the oil-pump mechanism,

replace the O-rings in the oil-pump cover and in the

oil pump adapter shaft (see Figure 5.7A). Rotate the

drive pin in the crankshaft to a vertical position for

easiest reassembly. Insert the shaft adapter so it

engages the drive pin. Next, insert the spring guide

and oil-pump assembly. The tang on the oil pump

must align with the slot in the shaft adapter. Install

the pump cover so the pin on the case is in the

opening on the oil-pump assembly as shown in

Figure 5.7A. When you are sure the pin is properly

aligned, install the cover bolts

finger tight

. Rotate

the crankshaft by hand to ensure smooth operation.

Then rotate it in opposite directions, listening for a

click which indicates proper alignment of the oil

pump's pins and slots. Finally, tighten the bolts in an

alternating sequence. See Section 3.3 for directions

on oil pressure adjustment.

Locate oil-filter adapter as shown

Oil Suction

Pin

Align slot (pump-shaft

adapter) with pin (crankshaft)

Align tang (oil-pump

assembly) with slot

(pump-shaft adapter)

Oil filter

O-ring

Pin (pump cover) must

fall in grooved area

(oil-pump assembly)

Oil Filter Adapter

Oil-pump Assembly

Spring Guide

Spring

Pump-shaft Adapter

O-ring

Pump-shaft

Bushing

Guage

For compressors without oil-filter assemblies use optional

pump cover. Assembly instructions are the same as above.

Tang