FD151 Gas Compressor 27

Piston must not touch cylinder!

To check this clearance, assembly personnel will need to check

clearance with feeler gauges.

An assembly tool must be used to line up the cylinder before it is tightened down.

1. Set cylinder on crosshead guide and start the 6-3/8-16 bolts.

2. Insert 1st Stage piston and tighten piston bolts.

3. Insert alignment tool (5276-X) on 2nd Stage piston rod (hand tight).

4. Rotate crank to align cylinder all the way through the stroke.

5. Tighten 3/8-16 bolts per torque specification in "Important Instructions: starting in the center and

working out.

6. Rotate crank to make sure the tool does not bind against the cylinder.

7. Remove tool, install piston and check clearance with feeler gauges.

8. If there is interference, repeat steps 1-7 until clearance is obtained.

9. When the clearance has been obtained, remove 2nd Stage piston. Torque to appropriate torque

specification in "Important Instructions".

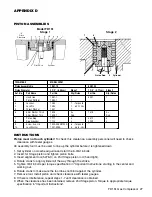

PISTON ASSEMBLIES

Model FD151

Stage 1

Stage 2

TWO-STAGE

MODEL FD151

Piston Assembly No.

1981-1X

5201-XC

Piston Diameter

2-1/2” (6.35 cm)

Stage 1

1-1/4” (3.17 cm)

Stage 2

Ref. No.

Part Name

Part No.

Qty./Piston

Part No.

Qty./Piston

1.

Head, Iron

1981-1

1

5201

1

2.

Piston Platform

1982-1

1

3.

Locknut

1482

1 -Torque to

4.

Lock Pin

1483

1 60 Ft. Lbs.

5.

Thrust Washer

1527

1

6.

Shim Washer, Thick

1528

As

1378

As

Shim Washer, Thin

1528-1

Req.

Req.

7.

Piston Ring

1771

3

3572

3

8.

Ring Expander

1774

3

4209

3

9.

Screw, Sco. Hd.

7002-008 NC125A

6 -Torque to

*

10.

Lock Washer

7207-008A

6 36 In. Lbs.

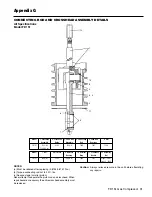

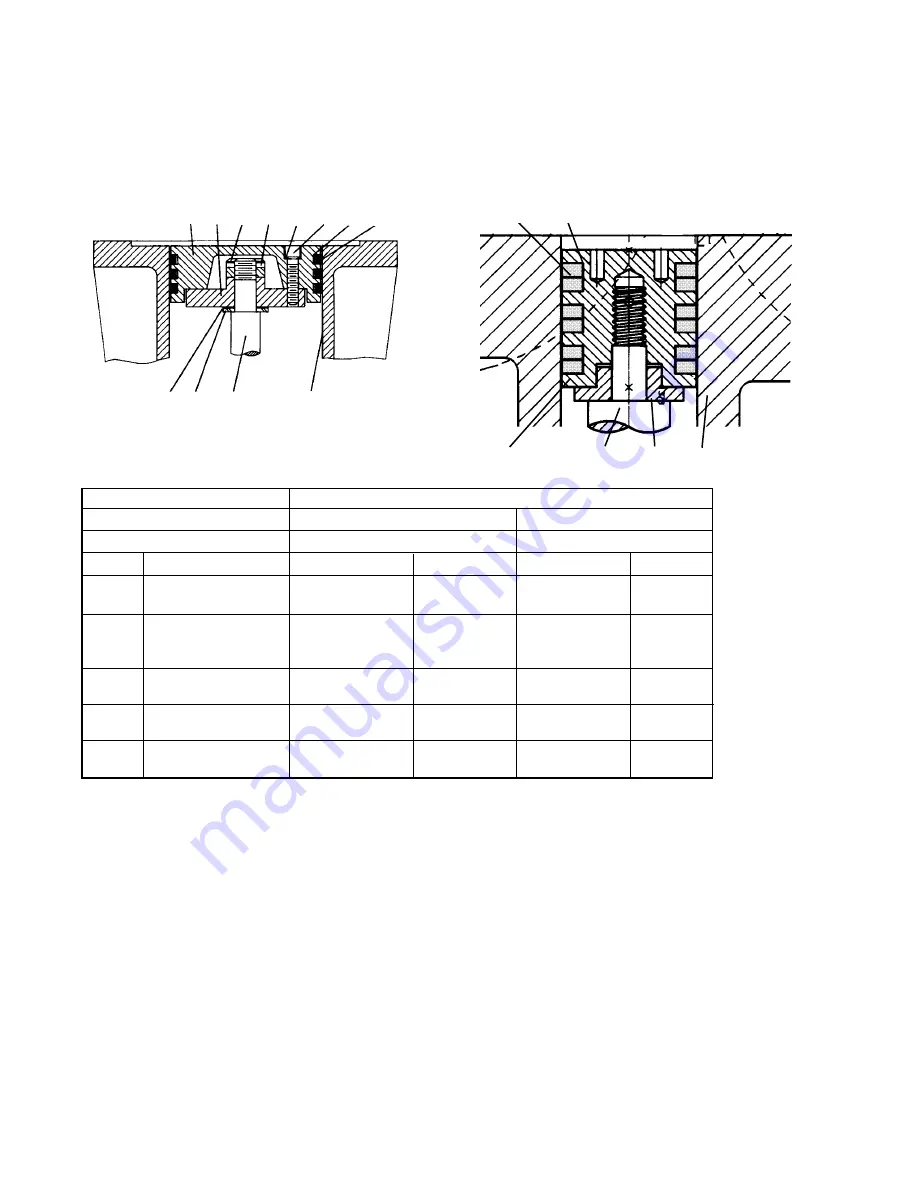

INSTRUCTIONS

7

8

1 Piston Rod 6 Cylinder

APPENDIX D

1

9

10

4

3

2

7

8

5

6

Piston Rod

Cylinder

“X”

Piston

Clearance