4 FD151 Gas Compressor

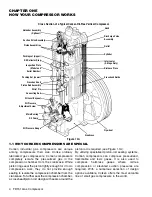

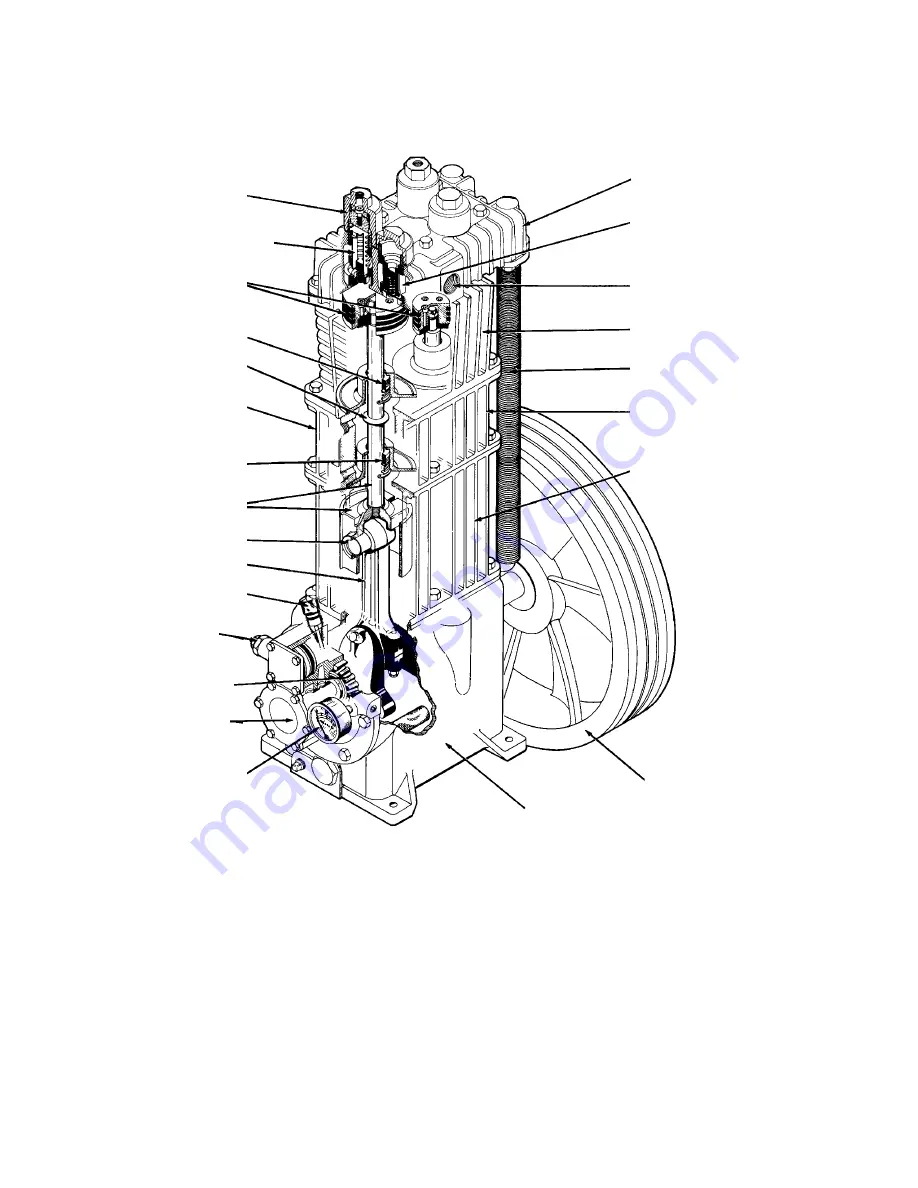

Corken industrial gas compressors are unique

among compressors their size. Unlike ordinary

lubricated gas compressors, Corken compressors

completely isolate the pressurized gas in the

compression chamber from the crankcase. While

piston rings seal the piston tightly enough for it to do

compression work, they do not provide enough

sealing to isolate the compression chamber from the

crankcase. To further seal the compression chamber,

a crosshead/piston rod design with seals around the

piston rod is required (see Figure 1.1A).

By utilizing specialized piston-rod sealing systems,

Corken compressors can compress pressurized,

flammable and toxic gases. It is also used to

compress harmless gases where oil-free

compression or elevated suction pressures are

required. With a numerous selection of design

options available, Corken offers the most versatile

line of small gas compressors in the world.

1.1 WHY CORKEN COMPRESSORS ARE SPECIAL

Unloader Assembly

(Optional)

Piston Assemblies

Packing set (Upper)

Suction Valve Assembly

Oil Deflector Ring

Packing Set (Lower)

Wrist Pin

Connecting Rod

Oil Level Bayonet

Main Bearing

Inspection Plate

(Model and

Serial Number)

Crosshead and

Piston Rod Assembly

Oil Pressure

Adjustment Screw

Oil Pump

Oil Pressure Gauge

Head

Discharge Valve

Assembly

Outlet

Cylinder

Intercooler

(2-Stage Only)

Distance Piece

Crosshead Guide

Crankcase

Flywheel

Figure 1.1A

Cross Section of a Typical Corken Oil-Free Vertical Compressor

CHAPTER ONE

HOW YOUR COMPRESSOR WORKS